F

BRAKES,

WHEELS

AND

TIRES

SECTION

F25

Regular checks should

be

made for flints, nails,

small

stones

etc., which should be

removed

from

the

tread

or

they

may

ultimately

penetrate

and damage

the

casing and puncture

the

tube.

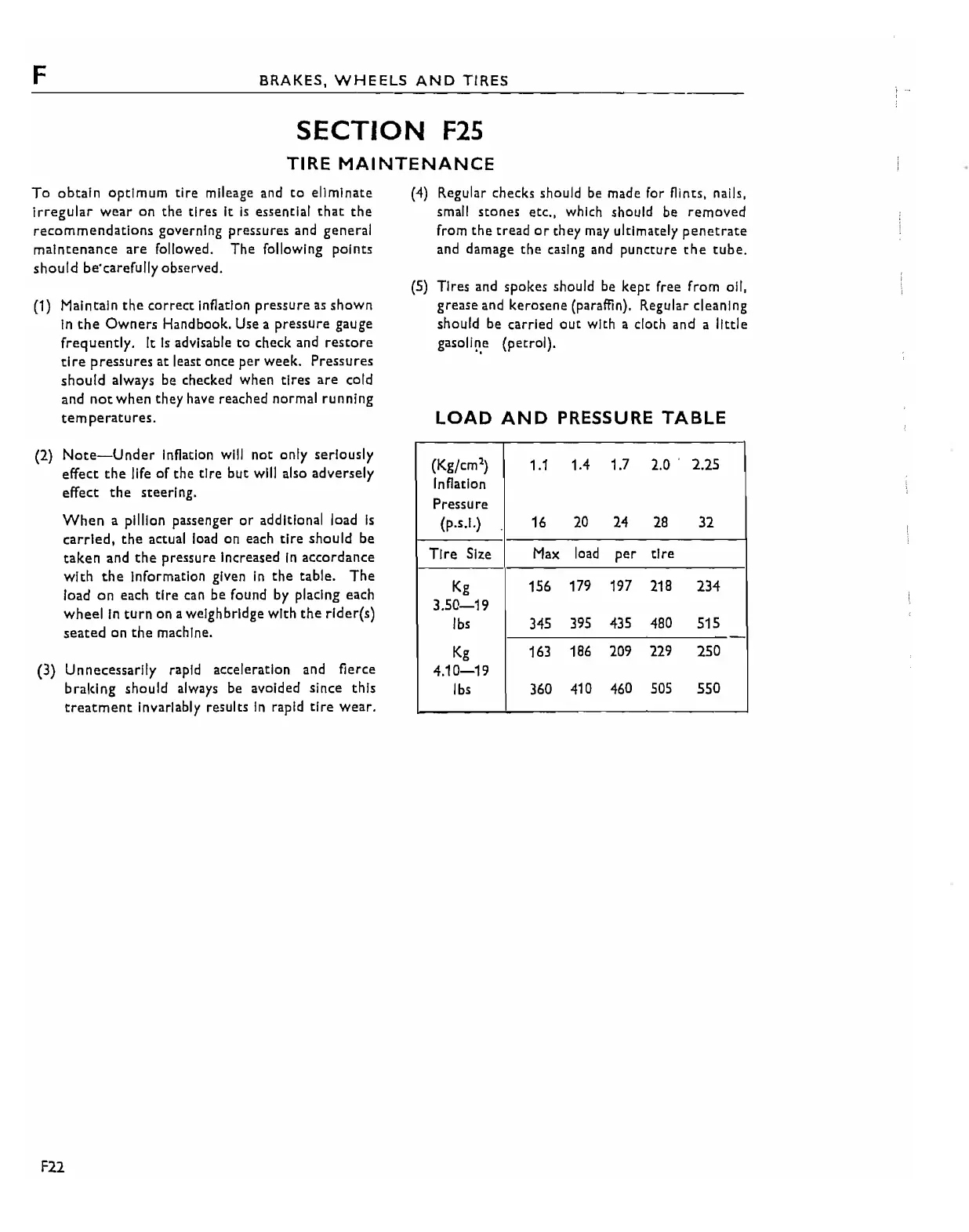

LOAD

AND

PRESSURE

TABLE

(5) Tires and spokes should

be

kept

free from oil,

grease and

kerosene

(paraffin), Regular cleaning

should be carried

out

with a cloth and a

little

gasoli~,e

(petrol).

TIRE

MAINTENANCE

(4)

(1) Maintain

the

correct

Inflation

pressure

as

shown

In

the

Owners

Handbook. Use a

pressure

gauge

frequently.

It

Is

advisable

to

check and

restore

tire

pressures

at

least once per week. Pressures

should

always be checked when

tires

are

cold

and

notwhen they

have

reached

normal

running

temperatures.

To

obtain optimum tire mileage

and

to

eliminate

irregular

wear

on

the tires

It

is

essential

that

the

recommendations governing pressures

and

general

malntenante

are

followed. The folloWing points

should

be'carefully observed.

(2)

Note-Under

Inflation will

not

only

seriously

effect

the

life

of

the

tire

but

will also adversely

effect

the

steering.

When

a pillion passenger

or

additional load

Is

carried,

the

actual load on each

tire

should

be

taken

and

the

pressure increased

In

accordance

with

the

Information given

In

the

table.

The

load

on

each

tire

can

be

found by placing each

wheel

In

turn

on a weigh bridge with

the

rlder(s)

seated

on

the machine.

(3) Unnecessarily rapid acceleration and flerce

braking

should always be avoided since this

treatment

Invariably

results

In

rapid

tire wear.

(Kg/cm')

1.1

1.4

1.7

2.0

.

2.25

Inflation

Pressure

(p.s.!.)

16

20

24

28

32

Tire

Size Max

load

per

tire

Kg

156

179

197

218

234

3.50-19

Ibs

345

395

435

480

515

Kg

163

186

209

229

250

4.10-19

Ibs

360

410

460

505

550

F22

Loading...

Loading...