8

ENGINE

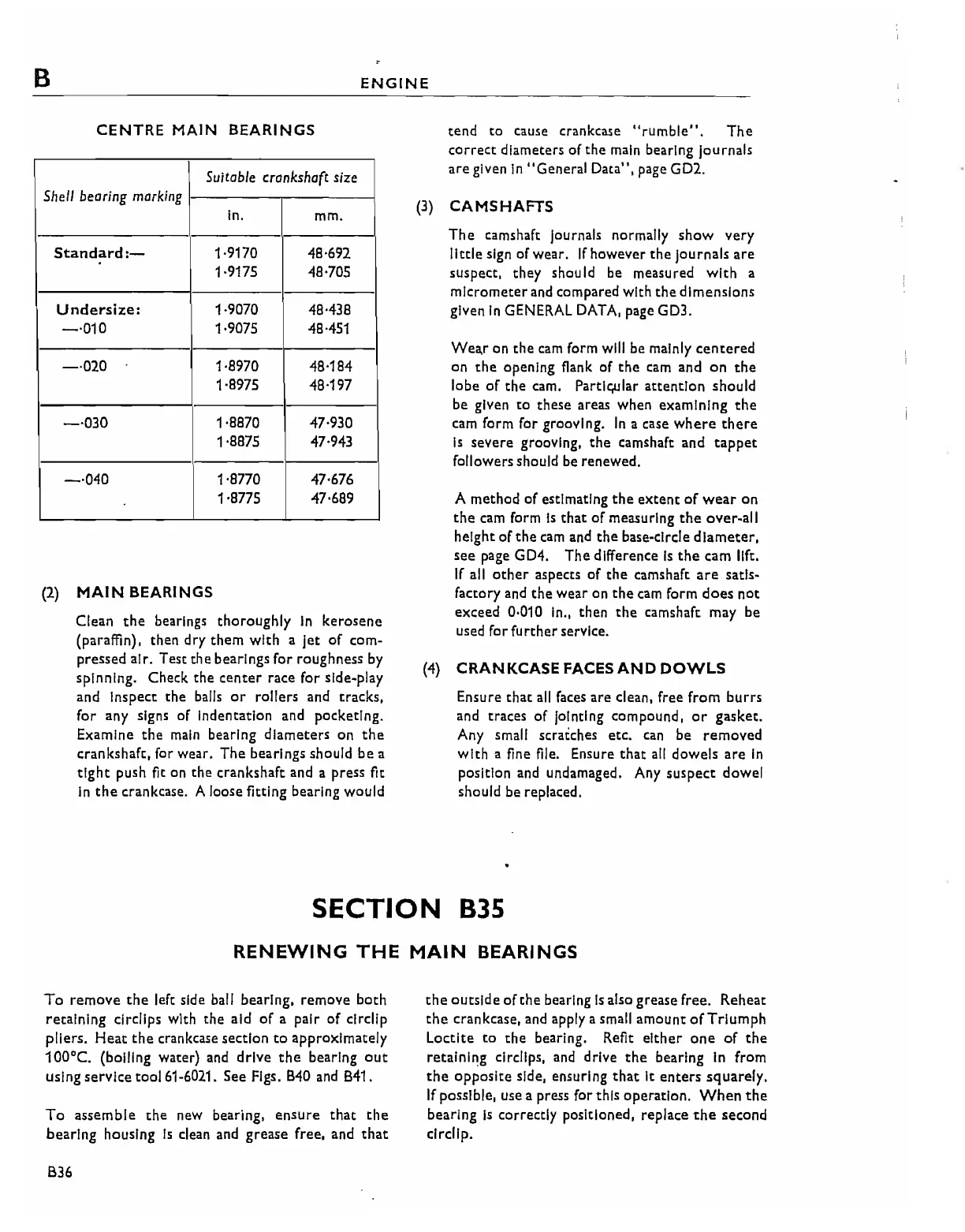

CENTRE

MAIN

BEARINGS

Suitable crankshaft size

Sheil bearing marking

in.

mm.

standard:-

1-9170 48·692

1·9175

48-705

Undersize:

1-9070

48·438

-·010

1-9075

48·451

-·020

1·8970 48·184

1·8975 48·197

-·030

1·8870

47·930

1·8875 47·943

-·040

1·8770

47·676

1·8775 47·689

(2)

MAIN

BEARINGS

Clean

the

bearings thoroughly

In

kerosene

(paraffin), then dry them with a Jet

of

com-

pressed air. Test the bearings for roughness

by

spinning. Check the

center

race for side-play

and inspect the balls

or

rollers and tracks,

for any signs of Indentation and pocketing.

Examine

the

main

bearing

diameters

on

the

crankshaft, for wear.

The

bearings should

be

a

tight

push fit on the crankshaft and a press fit

in

the

crankcase. A loose fitting bearing would

tend

to

cause crankcase

"rumble".

The

correct

diameters

of

the

main

bearing journals

are given

In

"General Data",

page

GD2.

(3)

CAMSHAFTS

The

camshaft Journals normally

show

very

little

sign of wear.

If

however

the

Journals

are

suspect, they should be measured

with

a

micrometer and compared with

the

dimensions

given

In

GENERAL

DATA,

page GD3.

Wea,r on the cam form will be mainly

centered

on

the

opening flank of

the

cam and

on

the

lobe

of

the cam. Partic;ular

attention

should

be given

to

these areas when examining

the

cam form for grooving.

In

a case

where

there

is

severe grooving,

the

camshaft and

tappet

followers should be renewed.

A method of estimating

the

extent

of

wear

on

the

cam form

Is

that

of measuring

the

over-all

height of

the

cam

and

the

base-circle

diameter,

see

page GD4.

The

difference

Is

the

cam

11ft.

If

all

other

aspects of

the

camshaft

are

satis-

factory and

the

wear on

the

cam

form

does

not

exceed 0·010

In.,

then

the

camshaft may be

used for

fu

rther

service.

(4)

CRANKCASE

FACES

AND

DOWLs

Ensure that all faces are clean, free from burrs

and traces of jointing compound,

or

gasket.

Any small scraiches etc.

can

be removed

with

a fine file. Ensure

that

all

dowels

are

In

position and undamaged. Any suspect dowel

should be replaced.

SECTION 835

RENEWING

THE

MAIN

BEARINGS

To

remove

the

left side ball bearing, remove both

retaining clrclips with the aid

of

a pair

of

circllp

pliers.

Heat

the

crankcase section

to

approximately

100'C.

(boiling water) and drive

the

bearing

out

using service tool 61-6021. See Figs.

B40

and B41.

To

assemble

the

neW

bearing,

ensure

that

the

bearing housing

is

dean and grease free, and

that

B36

the

outside

of

the

bearing

is

also grease free. Reheat

the

crankcase, and apply a small amount

of

Triumph

Loctlte

to

the

bearing. Refit

either

one

of

the

retaining circlips, and drive

the

bearing in from

the

oppOSite side, ensuring

that

it

enters

squarely.

If

possible, use a press for this operation.

When

the

bearing

is

correctly positioned, replace

the

second

drcllp.

Loading...

Loading...