LUBRICATION

SYSTEM

A

To

prevent

the

loss-of all from

the

oll.cooler and all

tank the ends of

the

pipes should be plugged

as

they

are disconnected.

When the valve has been

removed

t.he hexagonal

domed

cap

can be unscrewed from

the

main body,

thus releasing

the

piston which should be with-

drawn.

Thoroughly clean

all

parts

in

(kerosene) paraffin and

Inspect for wear.

If

any defect

is

apparent, e.g.

scoring

of

piston, spring fracture, etc.

the

whole

unit must be replaced.

When

screwing

the

relief

valve unit into the crankcase,

fit

a new fibre washer

between

the

body and

the

crankcase. (Figure

AS).

SECTION

A7

REMOVING

AND

REPLACING

THE

OIL

PUMP

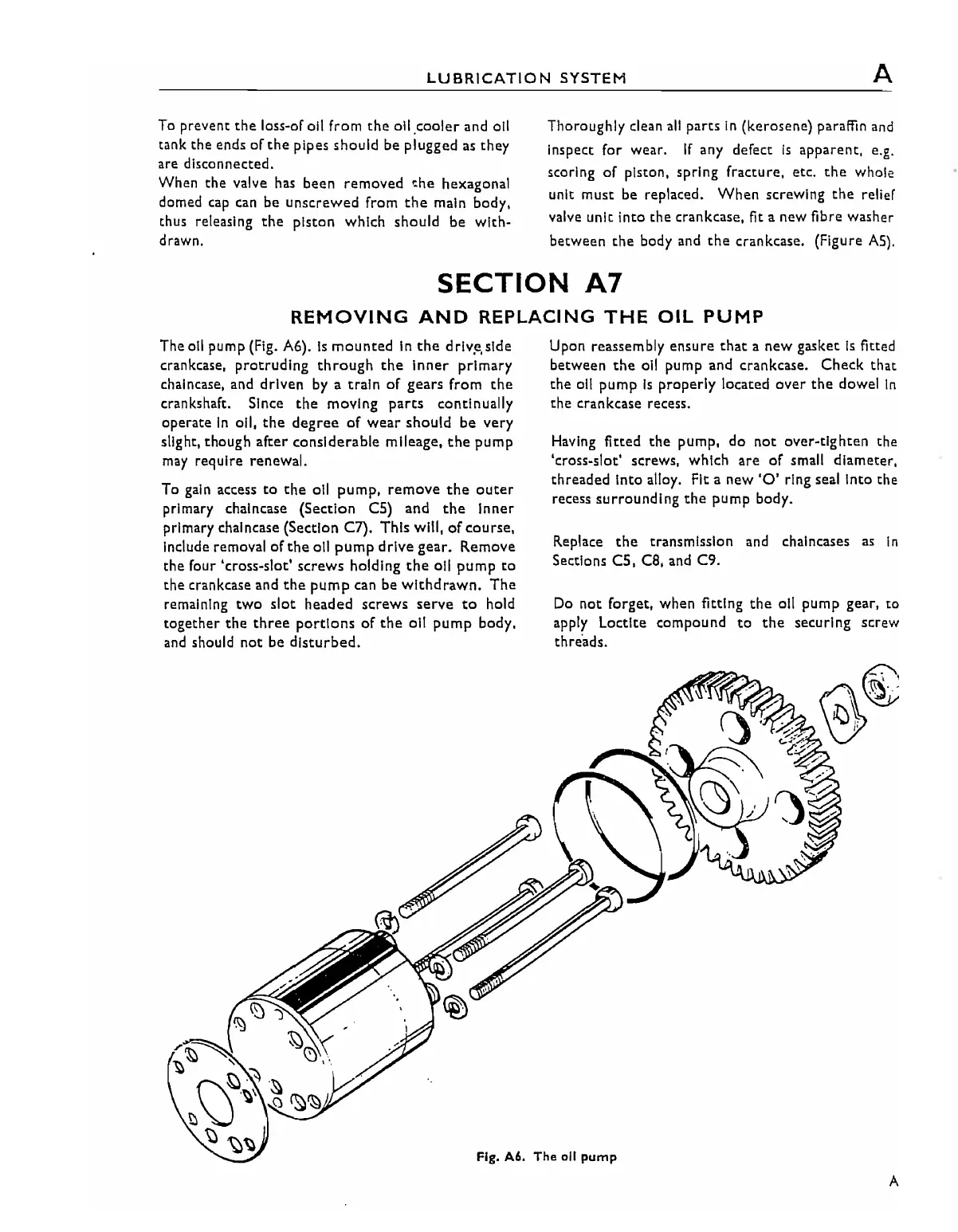

Theall pump (Fig. A6).

is

mounted

In

the

drlv.e,slde

crankcase,

protruding

through

the

Inner

primary

chalncase, and driven

by

a

train

of

gears from

the

crankshaft. Since

the

moving

parts

continually

operate

In

all,

the

degree

of

wear

should be very

slight, though after considerable mileage.

the

pump

may

require renewal.

To

gain

access

to the

011

pump, remove

the

outer

primary chalncase (Section

CS)

and

the

Inner

primary chalncase (Section C7). This will,

of

course,

Include removal of

the

oil

pump

drive gear. Remove

the four 'cross-slot' screws holding

the

oil pump

to

the crankcase and

the

pump

can be

withdrawn.

The

remaining

two

slot

headed screws

serve

to

hold

together

the

three

portions

of

the

011

pump

body,

and

should not be

disturbed.

Upon reassembly ensure

that

a new gasket

is

fitted

between

the

oil pump and crankcase. Check that

the

011

pump

Is

properly located

over

the

dowel

In

the crankcase recess.

Having fitted

the

pump, do

not

over-tighten the

Icross~slot'

screws, which are

of

small diameter,

threaded into alloy. Fit a new

'0'

ring seal into the

recess

surrounding

the

pump body.

Replace

the

transmission and chalncases

as

In

Sections C5,

ca,

and C9.

Do

not forget, when fitting

the

all pump gear, to

apply Loctlte compound

to

the

securing screw

threads.

Fig. A6. The all

pump

A9

Loading...

Loading...