B

ENGINE

SECTION

B6

REMOVING

AND

REPLACING

THE

AIR

FILTER

The

common air filter unit has

rubber

grommets

which fit

over

plain sleeves on

the

carburetor

Intakes

to

provide airtight joints and these

grom-

mets

must

be

In

good condition for

the

filter

to

be

effective

..

The whole assembly

Is

secured

to

the

carburetor

adaptor

by

means

of

two

bolts and

locknuts,

the

main nuts being Inside, and

part

of,

the

filter box.

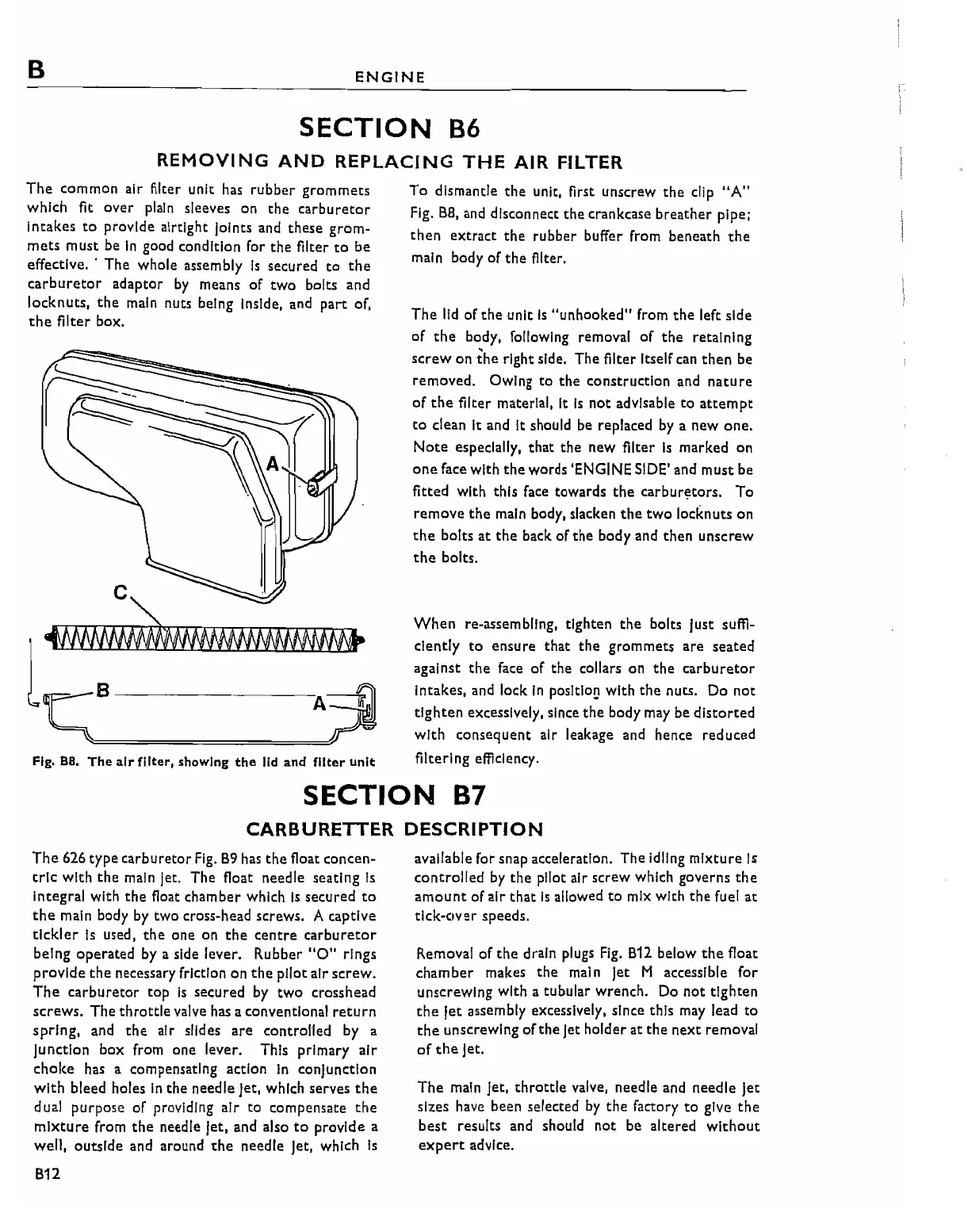

Fig.

B8.

The airfilter, showing

the

lid

and filter unit

To

dismantle

the

unit, first unscrew

the

clip

"A"

Fig.

B8,

and disconnect

the

crankcase

breather

pipe;

then

extract

the

rubber buffer from beneath

the

main body

of

the

fllter.

The

lid

of

the

unit

Is

"unhooked"

from

the

left side

of

the

body, following removal

of

the

retaining

screw

on

the

right side. The fllter Itself can

then

be

removed. Owing

to

the construction

and

nature

of

the

filter material, It

Is

not

advisable

to

attempt

to

clean It and It should be replaced

by

a new

one.

Note

especially,

that

the

new filter

Is

marked

on

one

face with

the

words 'ENGINE SIDE' and must

be

fitted with this face towards

the

carbur~tors.

To

remove

the

main body, slacken

the

two

locknuts

on

the

bolts

at

the

back

of

the

body and then unscrew

the

bolts.

When

re-assembling, tighten

the

bolts Just suffi-

ciently

to

ensure

that

the

grommets

are

seated

against

the

face

of

the

collars

on

the

carburetor

Intakes, and lock

In

posltlo~

with

the

nuts. Do

not

tighten

excessively, since

the

body may be

distorted

with

consequent air leakage and hence reduced

filtering efficiency.

SECTION

87

CARBURETTER

DESCRIPTION

The

626 type

carburetor

Fig.

B9

has

the

float concen-

tric

with

the

main Jet. The float needle seating

Is

Integral with

the

float chamber which

Is

secured

to

the

main body

by

two cross-head screws. A captive

tickler

Is

used,

the

one on

the

centre

carburetor

being

operated

by

a side lever. Rubber

"0"

rings

provide

the

necessary friction on

the

pilot air

screw.

The

carburetor

top

Is

secured by

two

crosshead

screws.

The

throttle

valve

has

a conventional

return

spring,

and

the

air slides

are

controlled by a

Junction

box

from one lever. This primary

air

cholte has a compensating action

in

conjunction

with

bleed holes

In

the

needle Jet, which serves

the

dual purpose

of

providing

air

to

compensate

the

mixture

from

the

needle Jet, and also

to

provide a

well, outside and around

the

needle Jet, which

Is

B12

available for snap acceleration. The Idling

mixture

Is

controlled

by

the

pilot air screw which governs

the

amount

of

air

that

Is

allowed

to

mix with

the

fuel

at

tlck-tlVer speeds.

Removal

of

the

drain plugs

Fig.

B12

below

the

float

chamber

makes

the

main Jet M accessible

for

unscrewing with a tubular wrench. Do

not

tighten

the

Jet

assembly excessively, since this may lead

to

the

unscrewing

of

the

Jet holder at

the

next

removal

of

the

Jet.

The

main Jet,

throttle

valve, needle and needle Jet

sizes have been selected

by

the

factory

to

give

the

best

results and should

not

be altered

without

expert

advice.

Loading...

Loading...