B

ENGINE

off

of

power

noticeable mainly on hills, a tendency

for

the

engine

to

run

hotter

than usual and

an

Increase In petrol consumption.

When

the

cylinder head

is

removed, unscrew

the

sparking

plugs and hate

them

grit-blasted and

checked. Before fltting

the

plugs, check

that

the

gap

setting

15

correct

as

listed

In

the

owners

handbook'.

Rotate

the

engine

to

bring each piston

In

turn

to

the

top

of

the

bore, and remove

the

carbon from

the

crown,

using a suitable scraper such

as

a stick

of

tinsmiths solder, flattened on

the

end to fOI m a

scraper.

Do

not

use a screwdriver

or

a steel Implement

of

any kind on an aluminium surface.

Leave a

narrow

ring

of

carbon round

the

edge

of

the

piston

crowns

and

do not remove the ring

of

carbon at the top or

the

cylinder bores.

An

old

piston ring placed

or,

top

of

the

piston wiil

assl't

In,

this operation.

After

cleaning

th~

pistons, again rotate

the

engIne

to

lower

the

pistons

to

the

bottom

of

their

bores

and wipe

all

loose carbon from

the

cylinder walls.

Remove

the

valves (Section

B13)

then

remove

the

carbon depos!ts

from

the valve stems, combustion

chamber

and ports of

the

cylinder head. Remove

all

traces

of

carbon dust

by

means

of

a

let

of

compressed

air

or

the vigorous use

of

a eyre pump,

then

thoroughly

clean the cylinder head and valves

In

kerosene

(paraffin). Finally, check

the

valves for

pitting.

If

necessary, the valves

can

be ground-in

as

shown

In

Section

B16.

SECTION

816

~E-SEATING

THE

VALVES

Examine

the

face

of

the

valve

to

see

if it

is

pitted,

burnt

or

damaged.

If

necessary,

the

face can be

reground.

but

excessive

re.grlndlng

Is

not

advisable

since

this

adversely affects

vapour

flow, and hence

performance, and will ultimately

result

in

critical

pocketing.

This,

in

turn,

will

require

excessive

Use

of

the

blending

cutter.

Where

the

valve guides have been renewed

or

the

condition

ofa

valve seat

Is

doubtful, It

is

advisable

to

re-cut

the

cylinder head valve

seat

then grind

In

the

valve, using a flne grade

of

grinding-In paste.

It

Is

important

that

the

cylinder head valve seat and

the

valve guide

bore

should be concentric. For

the

purpose

of

re-cuttlng

the

valve seats

the

following

service

tools

are available. (see tools section)

60-1833 Inlet

seat

cutter

(4S')

60-1832 Exhaust seat cUtter (4S')

60-1835 Exhaust seat blender

{

Holder-seat

cutters

60-1863

Pilot-seat

cutters

Tommy bar

Tommy

bar-cutter

pilot

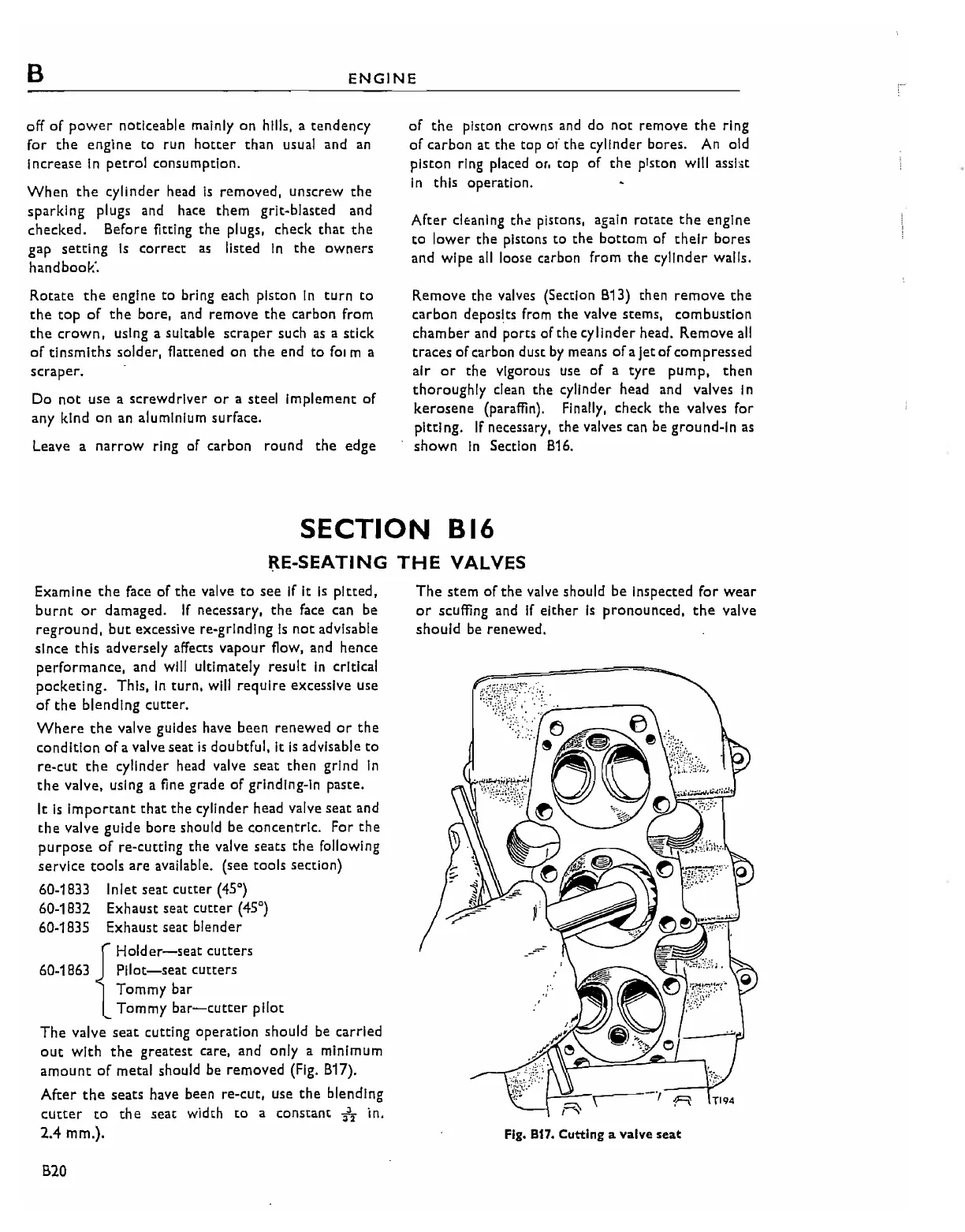

The

valve

seat

cutting operation should be carried

out

with

the

greatest care, and only a minimum

amount

of

metal should be removed (Fig. B17).

After

the

seats have been re-cut, use

the

blending

cUtter

to

the

seat width

to

a constant

:;JJ

z

in.

2.4

mm.).

B20

The

stem

of

the

valve should be inspected

for

wear

or

scuffing and

If

either

is

pronounced,

the

valve

should

be renewed.

--=--

t-''''---r----.,

I'

A

Fig.

B17.

Cutting a valve seat

Loading...

Loading...