ENGINE

B

------------------

SECTION

B5

ADJUSTING

THE

VALVE

ROCKER

CLEARA~CES

The valve

rocker

clearances should be checked and

If

necessary, adjusted

every

3,000 miles (5,000 Km),

The

correct

clearance for

the

type

of

camshaft

employed, ensures

that

a high valve operating

efficiency

Is

maintained, and

that

the

valves attain

their

maximum useful life.

NOTE:

Adjustment

should

only

be

":lade

when

the

engine

is

cold.

Access

to

'the

rocker

arm

adjuster

screws and lock-

ri~'ts

is

obtained

by

removing

both

the

Inlet and

exhaust rocker Inspection covers. These are

retained

by

four bolts and plain washers.

Adjustment

Is

carried

OUt

with a ring spanners (.5"

AF)

and an open end

spanner

(.25" AF).

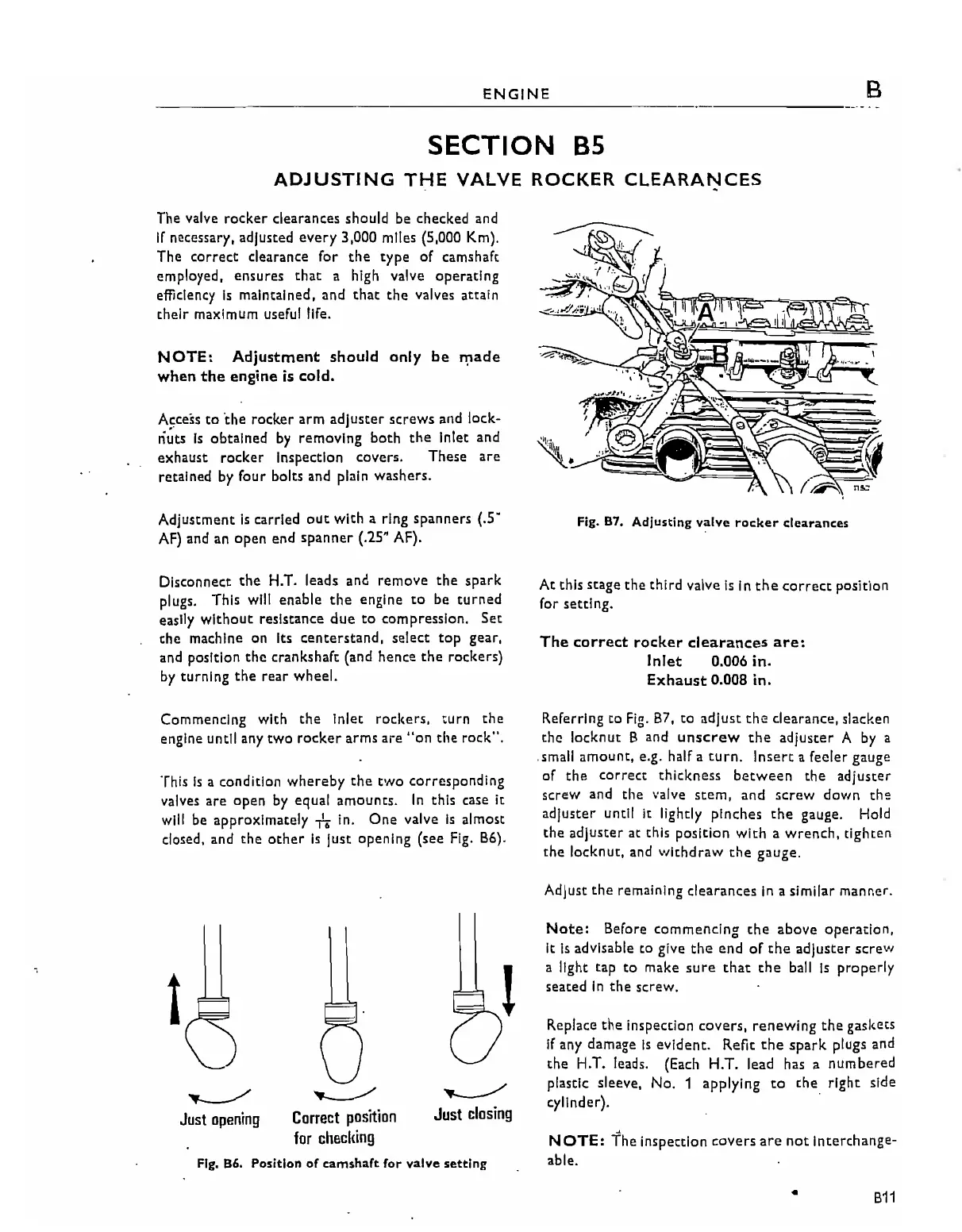

Fig.

87.

Adjusting

valve

rocker

clearances

Disconnect

the

H.T. leads and remove

the

spark

plugs. This will enable

the

engine

to

be

turned

easily

without

resistance

due

to

compression.

Set

the

machine on Its

centerstand,

select

top

gear,

and position

the

crankshaft (and hence

the

rockers)

by

turning

the

rear

wheel.

At

this stage

the

third valve

Is

in

the

correct

position

for setting.

The

correct

rocker

clearances

are:

Inlet

0.006

in.

Exhaust

0.008

in.

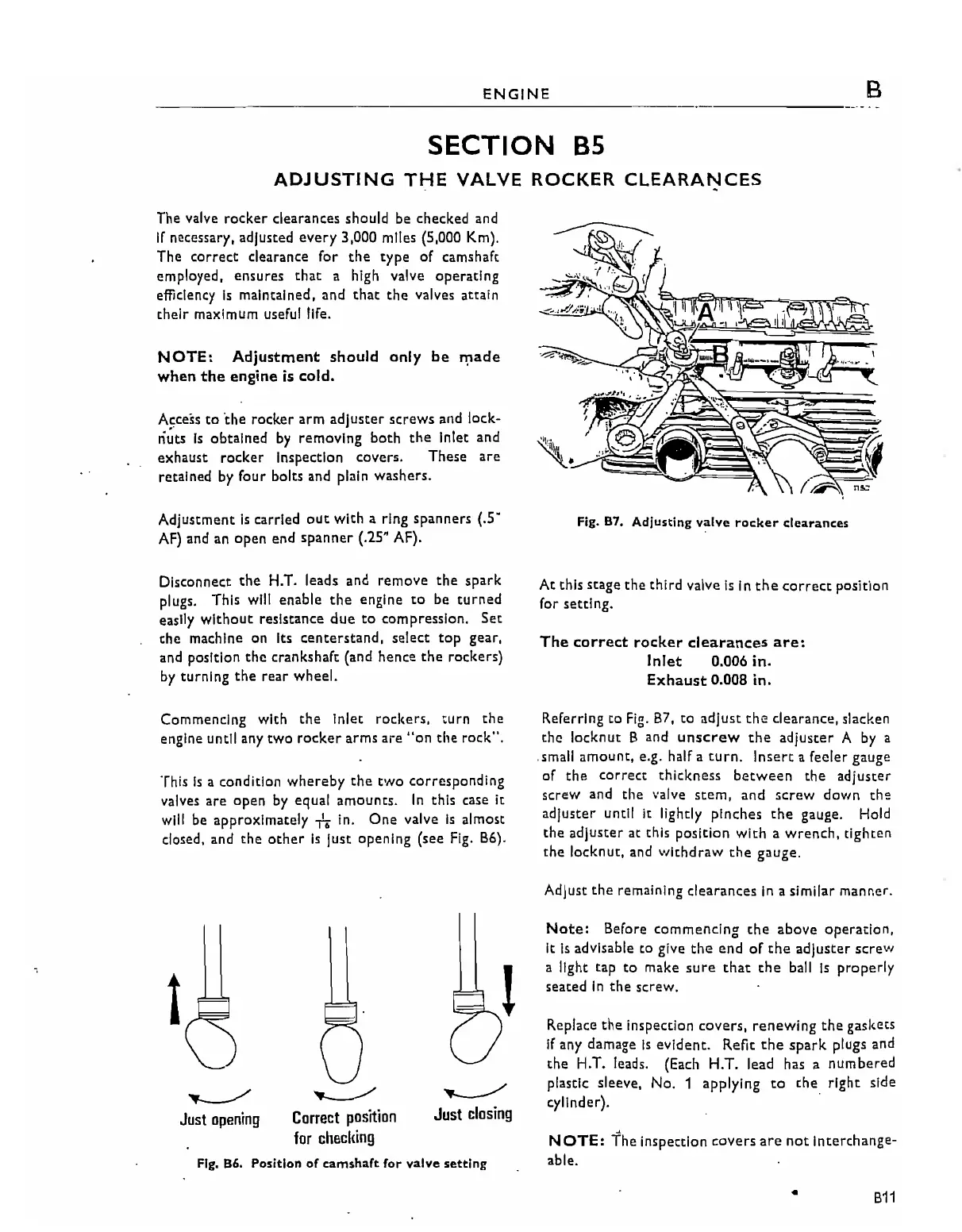

Commencing with

the

inlet

rockers,

turn

the

engine

until

any

two rocker

arms

are "on the rock",

This

Is

a condition

whereby

the

two

corresponding

valves are open

by

equal amounts.

In

this

case

it

will be approximately

+.

in.

One

valve

is

almost

closed. and

the

other

is

just

opening (see

Fig.

Bb).

Referring to

Fig.

B7,

to

adjust

the

clearance, slacken

the

locknut B and

unscrew

the

adjuster

A

by

a

small amount, e.g. half a

turn.

Insert

a feeler gauge

of the correct thickness

between

the adjuster

screw

and

the

....

alve

stem,

and

screw

down

th:!

adjuster until It lightly pinches

the

gauge. Hold

the

adjuster at this

position

with

a

wrench,

tighten

the

locknut, and

withdraw

the

gauge,

Adjust the remaining clearances

In

a,similar manner.

Fig.

86.

Position

of

camshaft

for

valve

setting

NOTE:

The inspection

covers

are

not

interthange-

able.

Replace the inspection covers,

renewing

the

gaskets

If

any damage

Is

evident.

Refit

the

spark

plugs and

the

H.T. leads. (Each H.T. lead has a

numbered

plastic sleeve, No. 1 applying

to

the

right side

~Iinde~.

.

Note:

Before commencing the above operation,

it

is

advisable

to

give

the

end

of

the

adjuster

screw

a light tap

to

make

sure

that

the

ball

Is

properly

seated

In

the screw.

~

Just

closing

~

Correct

position

for

checlling

~

Just

opening

t

•

B11

Loading...

Loading...