ENGINE

..

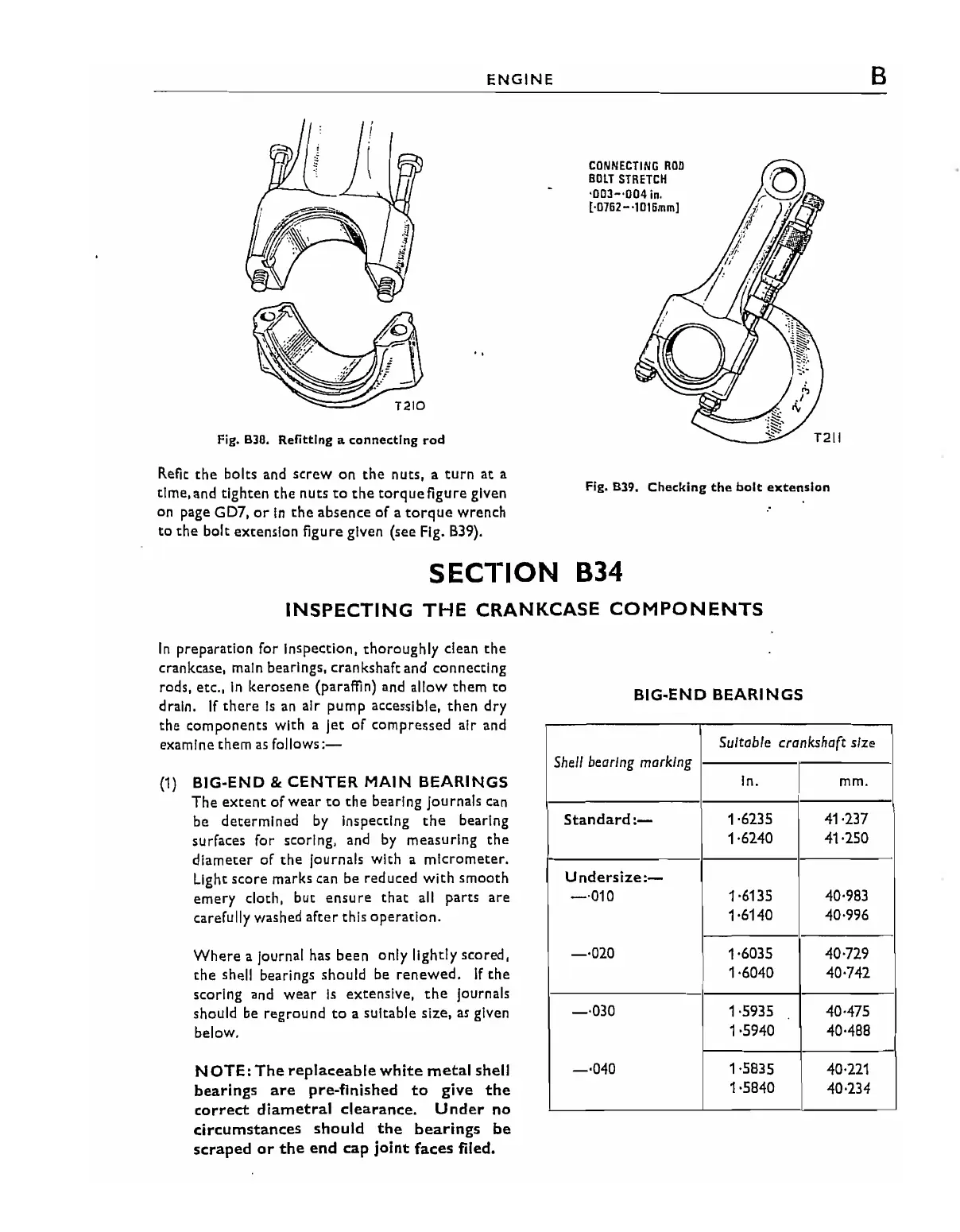

Fig. B38. RefittIng a connectIng

rod

Refit

the

bolts

and

screw

on

the

nuts, a turn at a

tlme,and tighten

the

nuts

to

the

torque

figure given

on page GD7,

or

In

the

absence

of

a

torque

wrench

to

the

bolt extension figure given (see Fig.

B39).

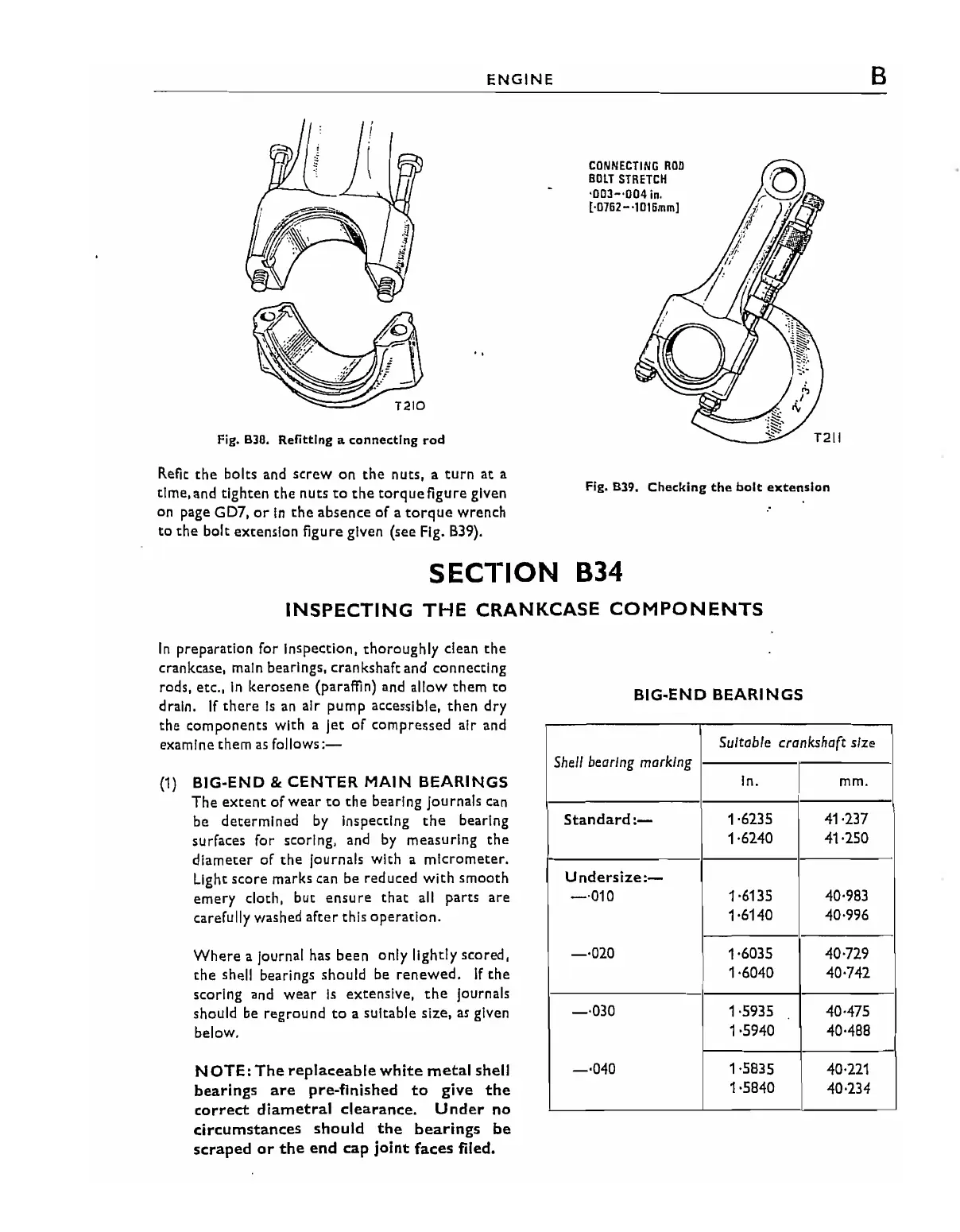

CONNECTING

ROO

BOLT

STRETCH

'003-'004

in.

[·0762-·1016mm]

Fig.

839.

Checking

the

bolt

extension

B

SECTION

834

INSPECTING

THE

CRANKCASE

COMPONENTS

In

preparation for Inspection,

thoroughly

clean

the

crankcase, main bearings, crankshaft and connecting

rods, etc.,

In

kerosene (paraffin) and allow them

to

drain.

If

there

Is

an

air pump accessible,

then

dry

the components with a

jet

of

compressed air and

examine them

as

fallaws:-

(1)

BIG-END &

CENTER

MAIN

BEARINGS

The

extent

of

wear

to

che bearing Journals can

be determined

by

Inspecting

the

bearing

surfaces for scoring, and

by

measuring

the

diameter

of

the

journals with a micrometer.

Light score marks can be reduced

with

smooth

emery cloth, but

ensure

that all parts are

carefully washed

after

this

operation.

Where

a Journal has been only lightly scored,

the

shell bearings should be

renewed.

If

the

scoring

and

wear

Is

extensive,

the

Journals

should be reground

to

a suitable size,

as

given

below.

NOTE:

The

replaceable

white

metal

shell

bearings

are

pre-finished

to

give

the

correct

diametral

clearance.

Under

no

circumstances

should

the

bearings

be

scraped

or

the

end

cap

joint

faces

filed.

BIG-END

BEARINGS

Suitable crankshaft size

Shell

bearing

markIng

In. mm.

Standard:-

1·6235 41·237

1·6240 41·250

Undersize:-

-·010

1·6135 40·983

1·6140

40·996

-·020

1·6035

40·729

1·6040 40·742

-·030

1·5935 40·475

1·5940

4Q.488

-·040

1·5835 40·221

1·5840 40·234

B35

Loading...

Loading...