B

ENGINE

Either camshaft

can

be

advanced or retarded

In

steps

of

15 degrees. which

Is

equal

to

one

tooth

on

the

camshaft

pinion.

or

5 degrees

by

assembiing

the

pinion on a different keyway.

Re-assembly notes

are

given

in

5ectlon

B29.

The

Ignition timing

procedure

is

fully described

in

Section

B26.

NOTE

When

checking

the

valve timing

after

assembly, due to the intermediate wheel having a

prime number of teeth, the timing

marks

will only

coincide every 94th revolution,

thus

there

Is

no

cause for alarm ifche marks will not readily re-allgn.

SECTION

831

TO

DISMANTLE

AND

REASSEMBLE

THE

CRANKCASE

(1) Remove

the

engine unit (Section

B1).

(2) Remove

the

rocker

boxes (Section

B2).

(3) Remove

the

carburetors

(Section

B8).

(4) Remove

the

cylinder head (Section 812).

(5) Remove

the

cylinder block (Section 817).

DO

NOT

FORGET

TO

PROTECT

THE

CONNECTING

RODS

FROM

DAMAGE.

(6) Remove

the

pistons (Section 820).

(7)

Remove

the

primary chain, engine

sprocket.

shock

absorber.

and gearshift crass-shaft.

(Section

C5-Cl).

(8) Remove

the

clutch and housing (Section C7).

(9) Remove

the

oil pump (Section A7).

(10) Remove

the

transmission (gearbox)

outer

cover (Section D2).

(11) Remove

the

transmission (gearbox) Inner

cover and

gear

cluster (Section D7).

(12) Remove

the

timing

cover

(Section

B28).

(13) Remove

the

rotar

and

stator.

To

remove

the

right side crankcase section

It

is

nOt necessary

to

remove the timing pinion

and

distance

piece.

If

for any reason

the

pinion

Is

removed,

note

that

this

Is

keyed

to

the

crankshaft

and

will need

the

use

of

an

extractor.

The

Intermediate

timing gear

with

Its retaining

circlip

and

thrustwasher must be removed next.

For valve timing purposes on re·assembly, refer

to

Section

B30.

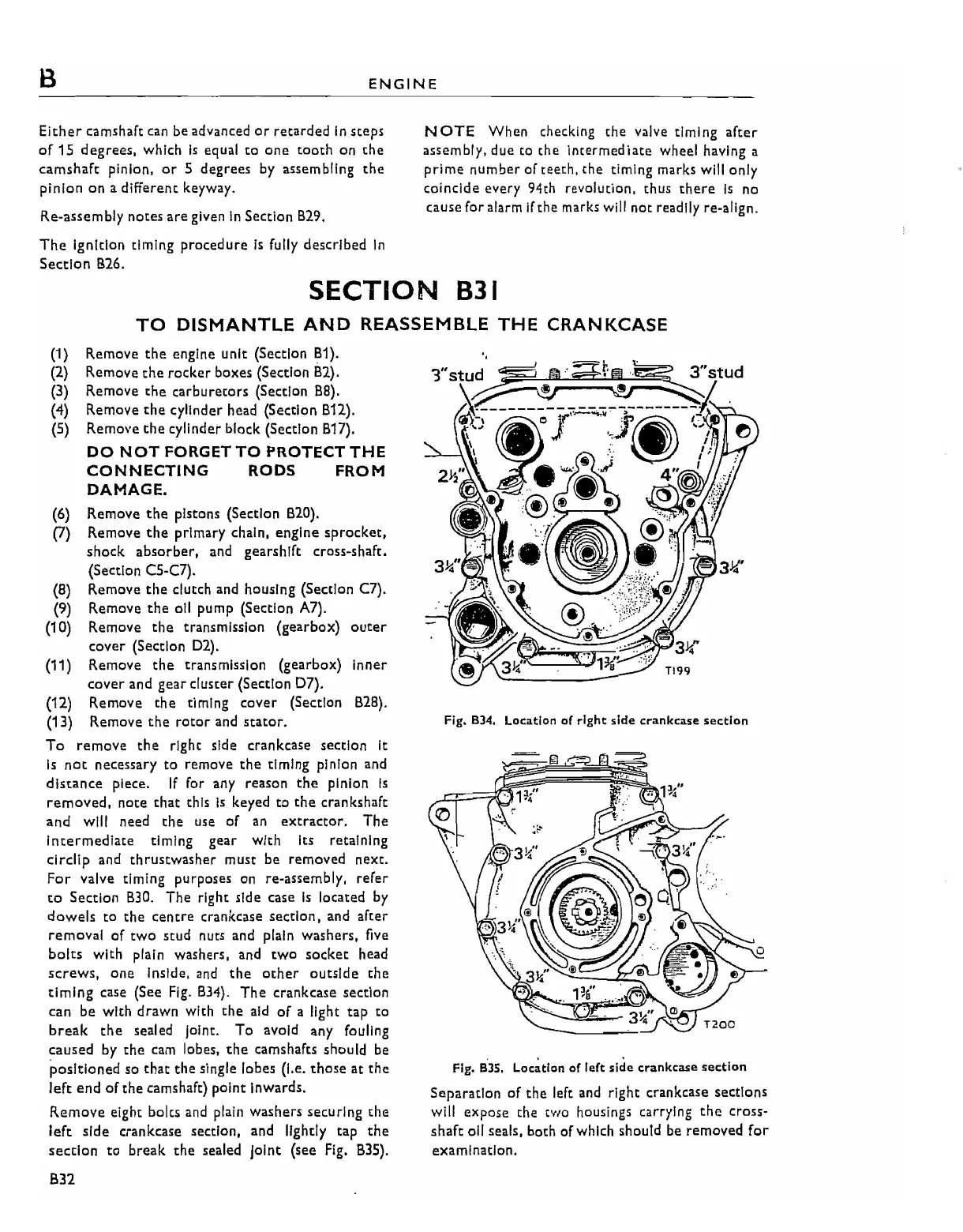

The right side case

Is

located

by

dowels

to

the

centre

crankcase

section,

and after

removal

of

two

scud

nuts

and

plain

washers, five

bolts

with plain washers. and

twO

socket

head

screws,

one

Inside,

and

the

other

outside

the

timing

case (See

Fig.

B34).

The

crankcase section

can be with drawn with

the

aid

of

a light

tap

to

break

the

sealed joint. To avoid any fouling

caused

by

the

cam lobes,

the

camshafts should be

positioned

so

that

the

single lobes (I.e.

those

at

the

left

end

of

the camshaft) point Inwards.

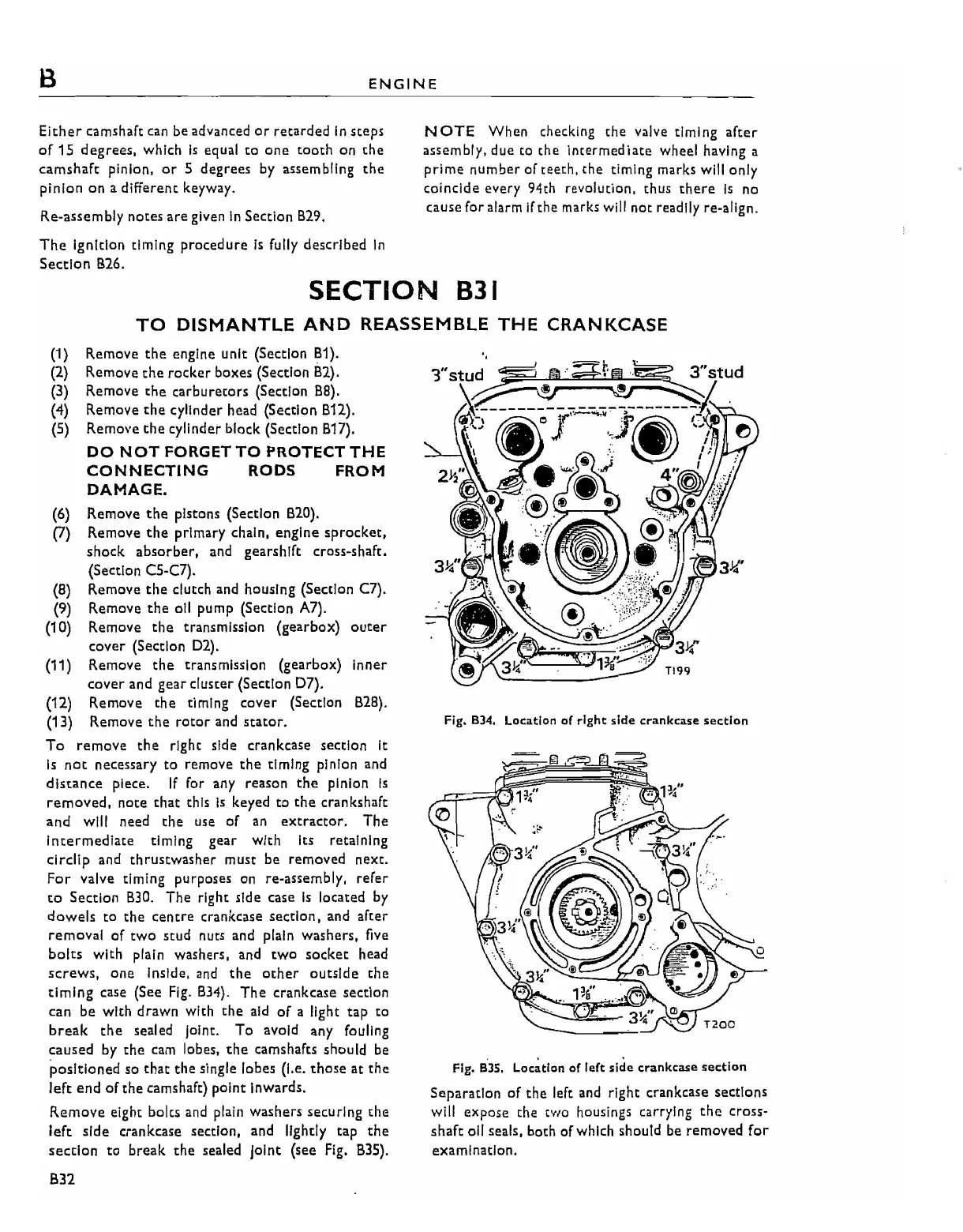

Remove

eight bolts and plain washers securing

the

left

side crankcase section, and lightly tap

the

section

to

break

the

sealed Joint (see

Fig.

835).

B32

Fig. 834. Location

of

right

side

crankcase

section

Fig.

BJS.

Loc~t1on

of

left

side

crankcase

section

Separation

of

the

left and right crankcase sections

will

expose

the two housings carrying the cross-

shaft

011

seals. both of which should be removed

for

examination.

Loading...

Loading...