ENGINE

SECTION

B4

STRIPPING

AND

REASSEMBLING

THE

ROCKER

BOXES

B

Removal of

the

rocker

spindles

from

the

rocker

boxes

Is

best achieved by

driving

them

out,

using a

soft metal drift.

When

the

spindles

are

removed,

the

rocker arms and

washers

can

be

withdrawn.

All

parts should

be

thoroughly

cleaned

in

kerosene,

(paraffin), and

the

oliways

In

the

spindles should be

cleaned with a

jet

of

compressed

air.

Remove

the

'0'

rings

from

the

rocker

splndle~

and

renew them.

If

It

Is

required

to

renew

the

rocker

ball pins,

the

old ones should

be

removed

by means

of

a suitable

drift. New ones should

then

be

pressed In.

To ensu re

an

oli-tlght seal

between

the

rocker

box

and cylinder head,

In

cases

where

an oli leak

cannot

be cured

by

fitting

new

gaskets,

the

Joint surface

of

the

rocker

box

should

be

IInlshed

to

remove

any

Irregularities.

An

effective finish can

be

achieved by lightly rubbing

the

junction surface

on

a

sheet

of

emery

cloth

mounted on a truly flat surface (such as a piece of

plate glass).

The following method

of

assembly

Incorporates

the

use

of a home made

alignment

bar. which can be

made from a

-{-;

In.

dla.

bar

X

9-!-

In. long

by

grinding

a taper at one end.

Smear

the

plain washers

with

grease

and place

them against the cast bosses or rocker arms

as

shown

In

Fig.

BS.

Commencing from

the

left end

of

each

rocker

box

(I.e. end with larger hole), fit

the

rocker

arms.

Compress each Thackery

washer

(double-coli) with

thin nosed pliers and assemble

these.

Align each

rocker

In

turn

with

the

alignment

bar.

When

all

the

arms and washers

are

correctly

aligned, remove

the

bar.

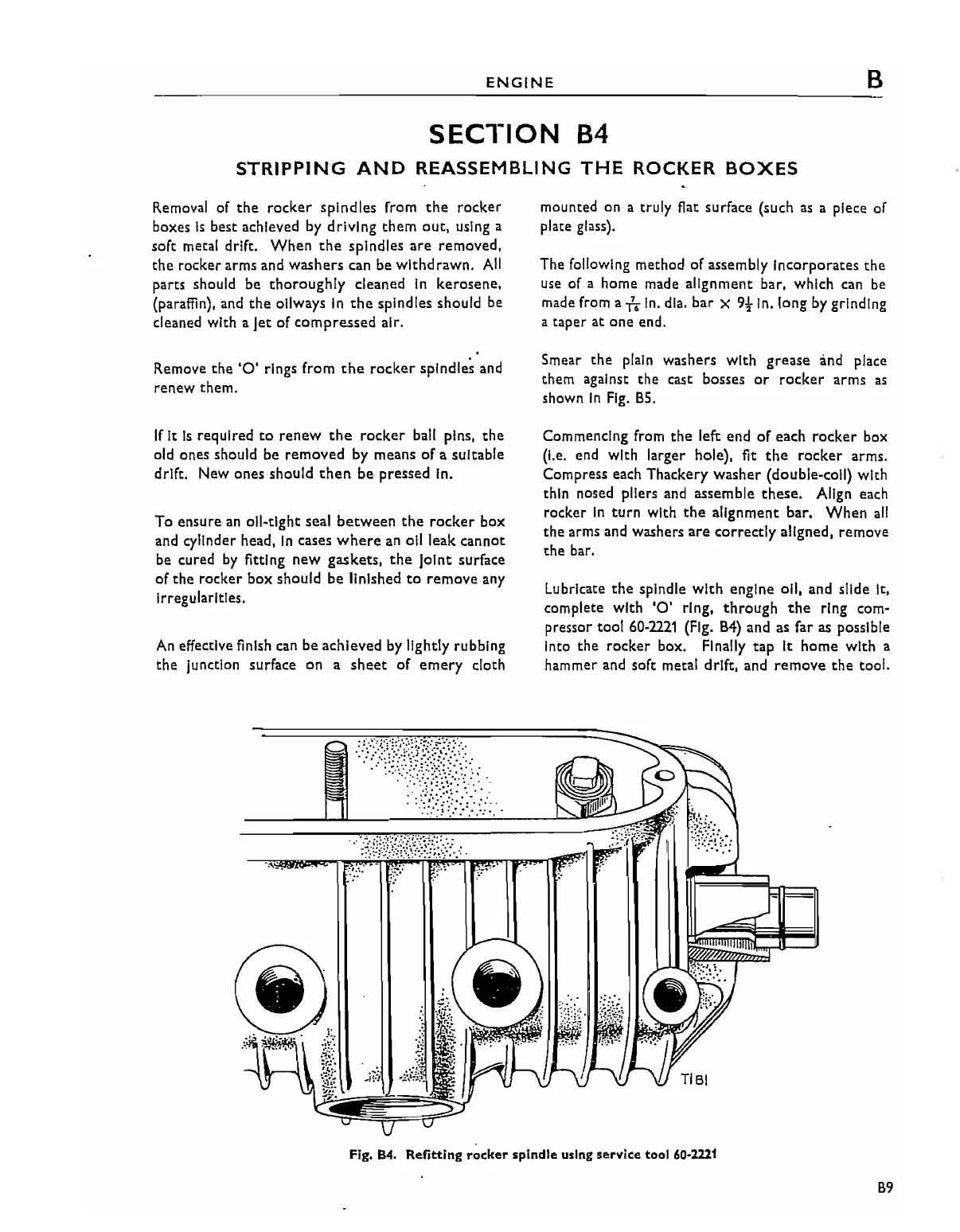

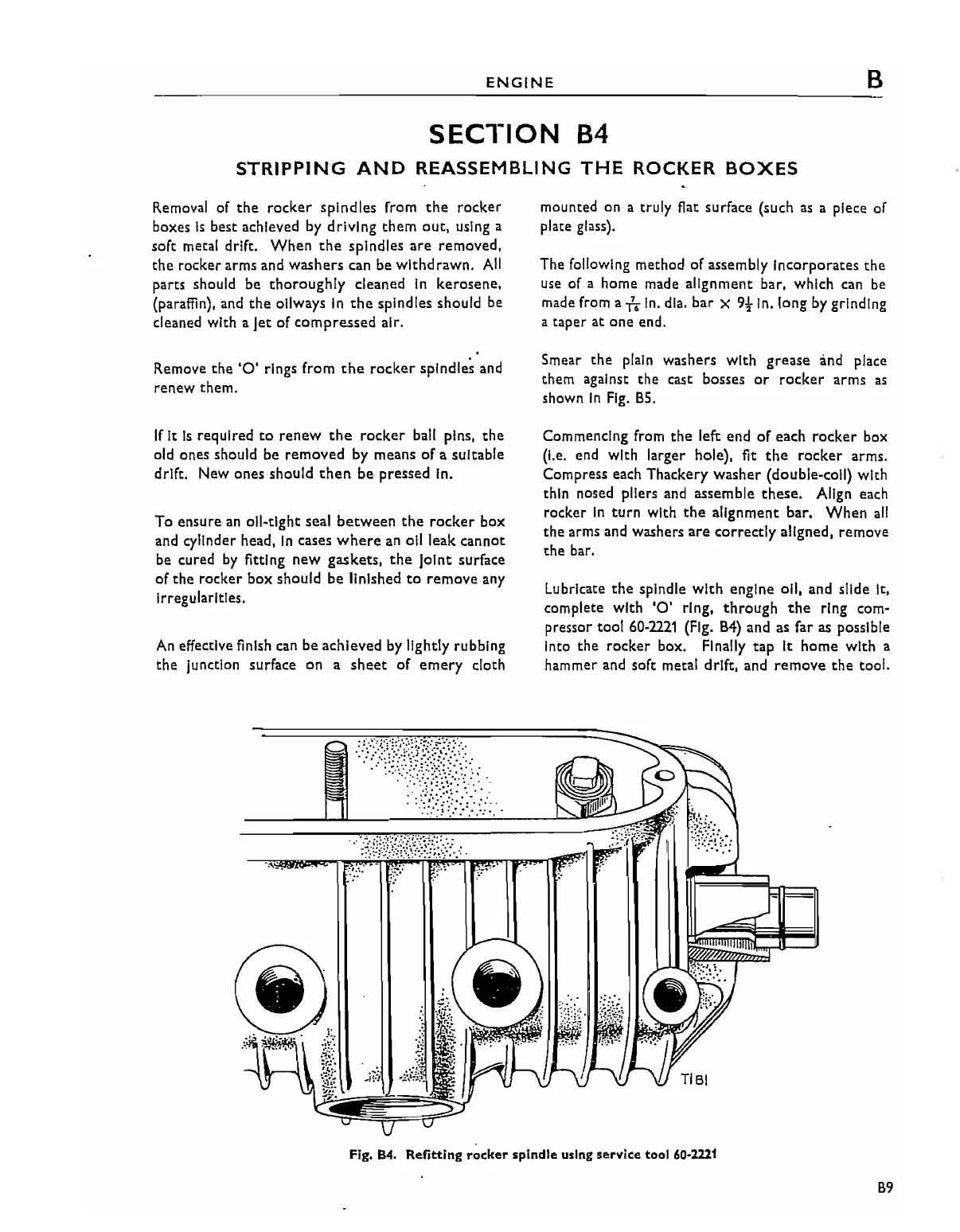

Lubricate

the

spindle

with

engine oil, and slide it,

complete with

'0'

ring,

through

the

ring com-

pressor

tool

60-2221

(Fig.

B4)

and as far as possible

Into

the

rocker

box. Finally

tap

It

home

with

a

hammer and soft metal drift, and

remove

the

tool.

Fig. 84. Refitting rocker spindle using service tool

60-2221

B9

Loading...

Loading...