PRIMARY DRIVE

SECTION

C9

PRIMARY

CHAIN

SPROCKET

ALIGNMENT

c

It

Is

essential

that

the

primary chain misalignment

does

not

exceed

0.010

In.

Owing

to

the

design of

the

primary transmission,

the

engine and shock

absorber

sprockets

cannot be

accurately aligned with

the

customary use of a

straight edge, unless used

In

conjunction with

a cutaway primary

outer

cover (Fig. C6).

Normal manufacturing tolerances, which apply

to

the

Inner and

outer

primary covers, and

all

other

components from which

the

shock

absorber

Is

constructed, create a variation

In

the

amount

of

shock

absorber

end-float. Since

operation

of

the

clutch presses

the

shock

absorber

assembly against

Its

thrust

bearing,

the

end

float

present

In

each

particular engine unit

must

be eliminated before

checking

the

alignment.

If

either

of

the

primary covers,

or

any

component

part of

the

shock

absorber,

Is

changed for any

reason,

the

amOunt

of

end-float will almost certainly

alter.

It

Is

also necessary

to

account for variations

In

the

thickness

of

the

primary

cover

gasket.

Sprocket alignment must be checked

without

the

chain

In

position.

Replace

the

engine

sprocket,

together

with any

shims formerly fitted

between

the

sprocket

and

the

oil pump drive gear behind It. Drive

the

sprocket

home with a

tubular

drift.

Carefully clean

the

Joint face

of

the

Inner cover and

add

the

gasket.

Replace

the

chainwheel assembly

onto

the

clutch

shaft splines and then fit

the

needle roller

thrust

bearing

to

the

Inner

face

of

the

chainwheel.

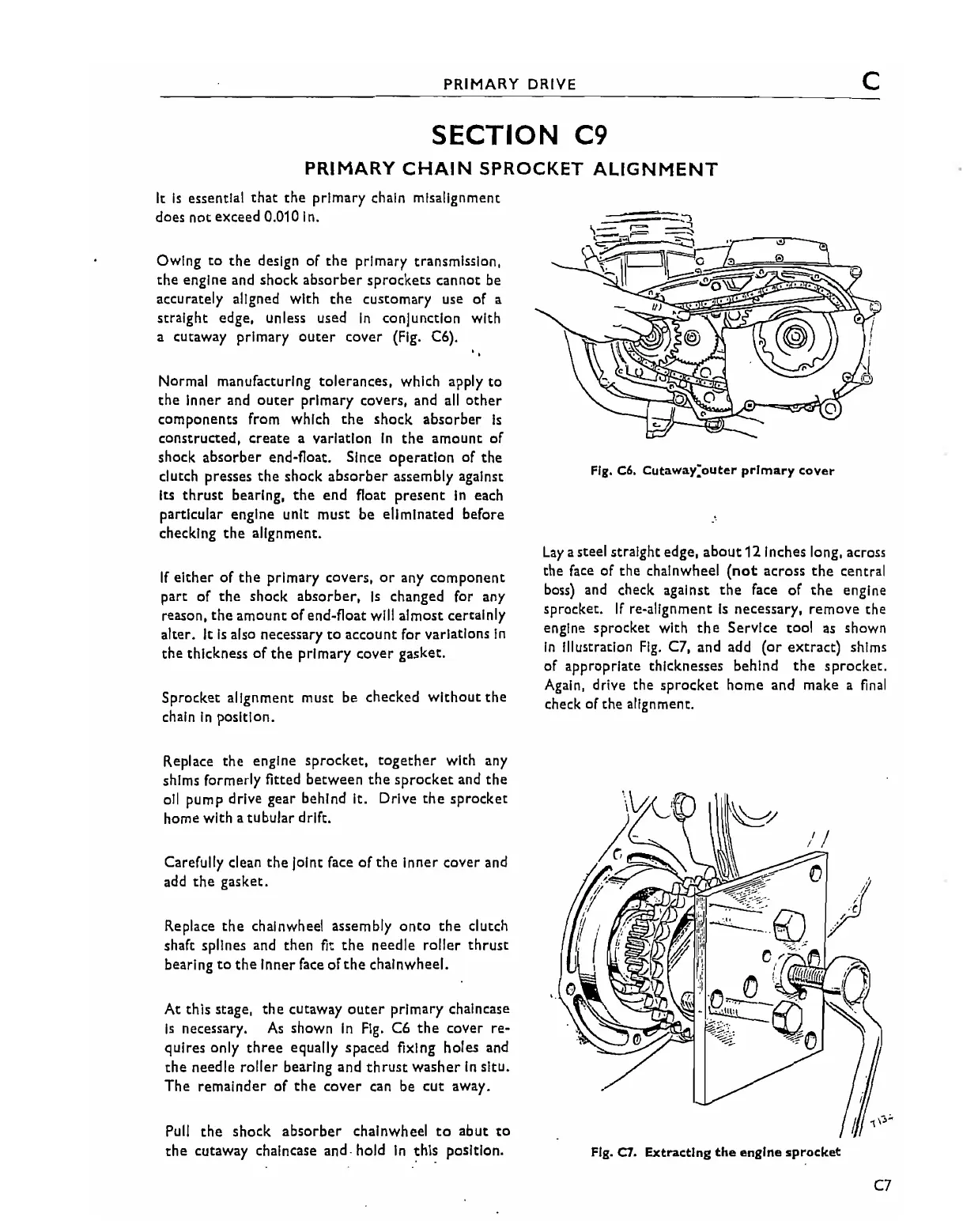

At

this stage,

the

cutaway

outer

primary chalncase

Is

necessary.

As

shown

In

Fig. C6

the

cover re-

quires only

three

equally spaced fiXing holes and

the

needle roller bearing and

thrust

washer

In

situ.

The

remainder

of

the

cover

can be

cut

away.

Pull

the

shock

absorber

chainwheel

to

abut

to

the

cutaway chalncase and. hold

In

this

position.

Fig.

C6.

Cutaway:outer primary

cover

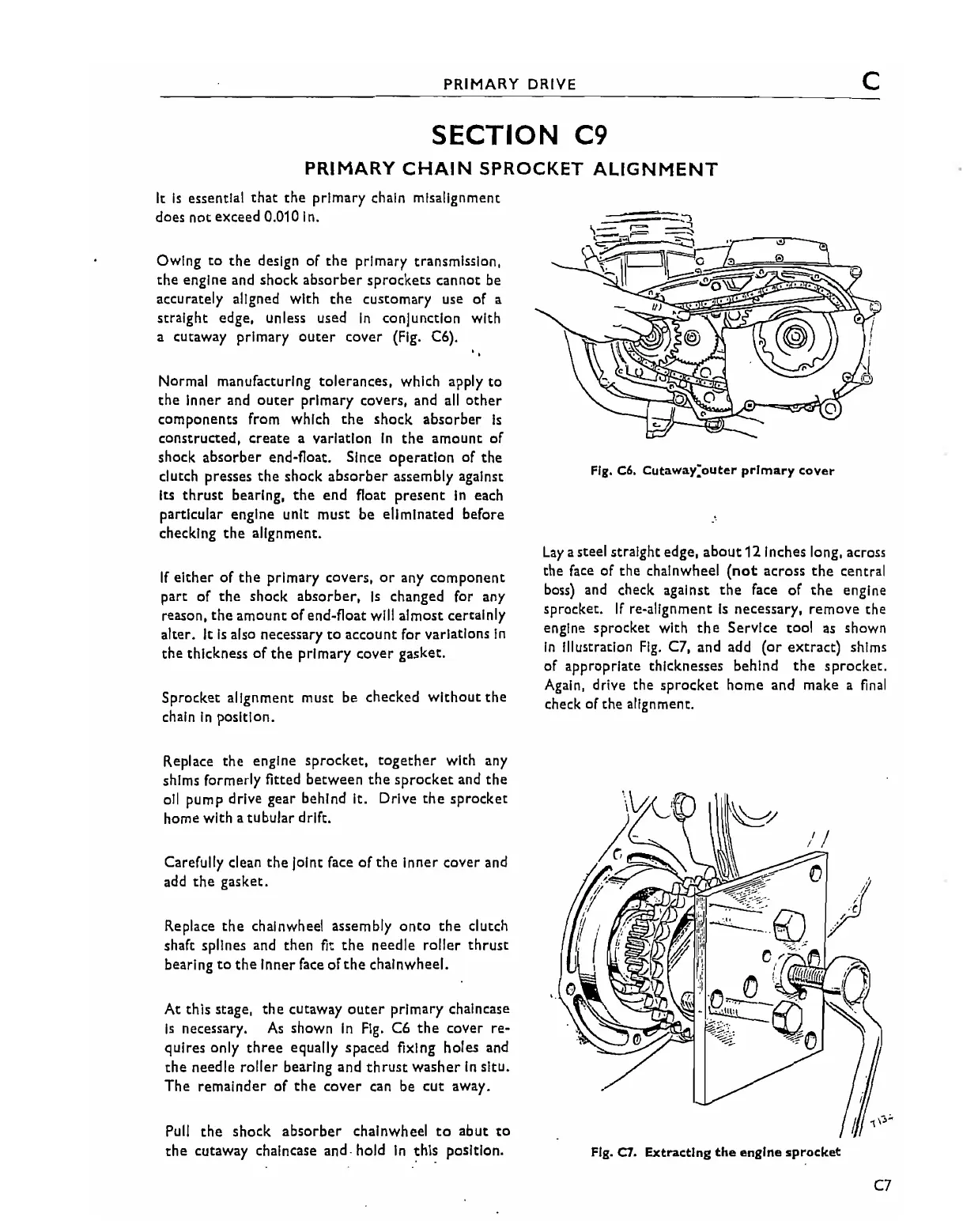

Lay

a steel straight edge,

about

121nches long, across

the

face

of the chainwheel

(not

across

the

central

boss) and check against

the

face

of

the

engine

sprocket.

If

re-alignment

Is

necessary, remove the

engine

sprocket

with

the

Service tool as shown

In

Illustration

Fig.

C7, and add

(or

extract)

shims

of appropriate thicknesses behind

the

sprocket.

Again, drive the

sprocket

home and make a

final

check of

the

alignment.

Fig.

C7.

Extracting

the

engine

sprocket

C7

Loading...

Loading...