ENGINE

B

x

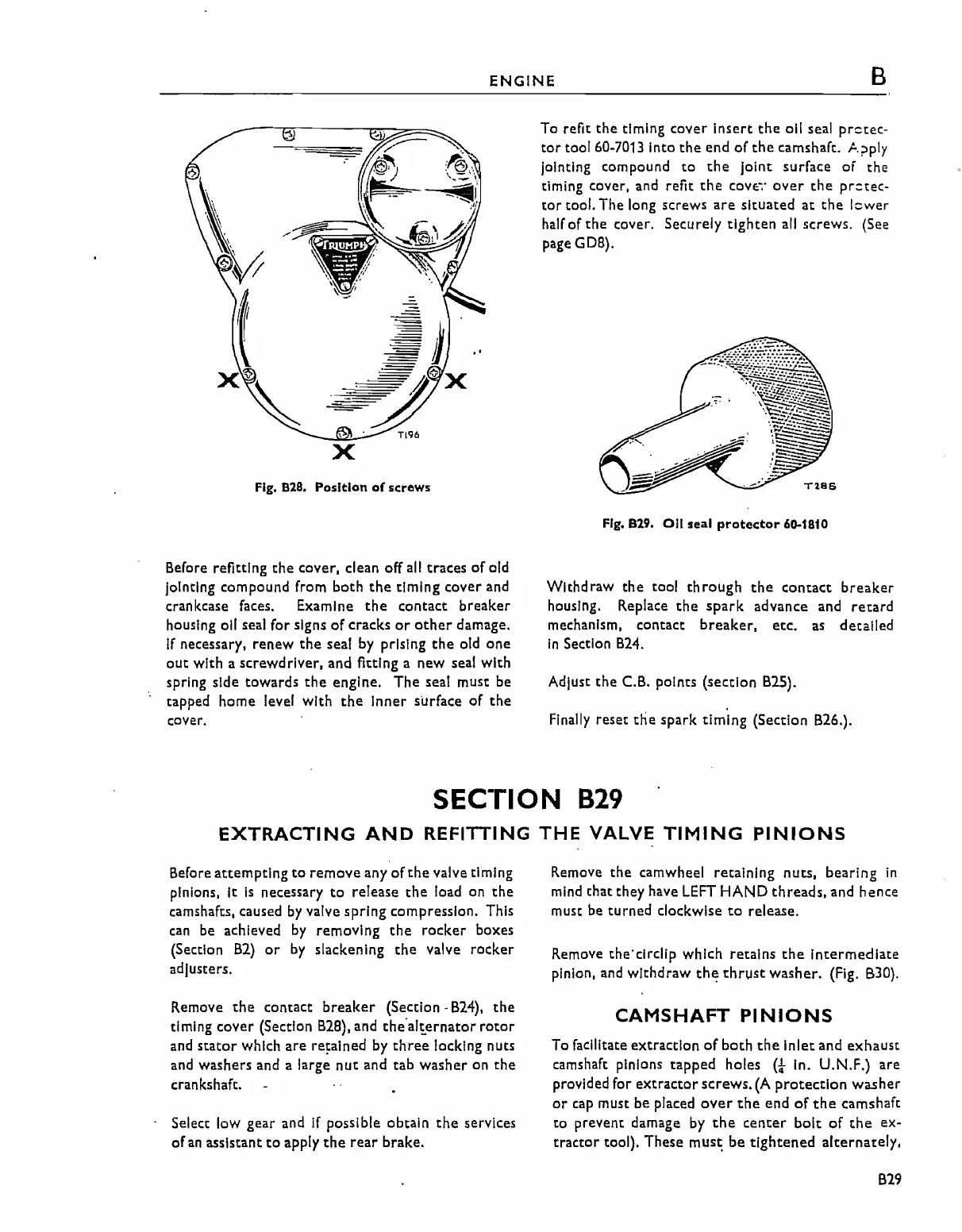

Fig,

828. Position

of

strews

Before refitting

the

cover,

dean

off

all

traces

of

old

Jointing compound from both

the

timing cover and

crankcase faces. Examine

the

contact breaker

housing

011

seal for signs

of

cracks

or

other

damage.

If

necessary, renew

the

seal

by

prlslng

the

old one

out

with a screwdriver, and fitting a new seal with

spring side towards

the

engine. The seal must be

tapped home level with

the

Inner surface

of

the

cover.

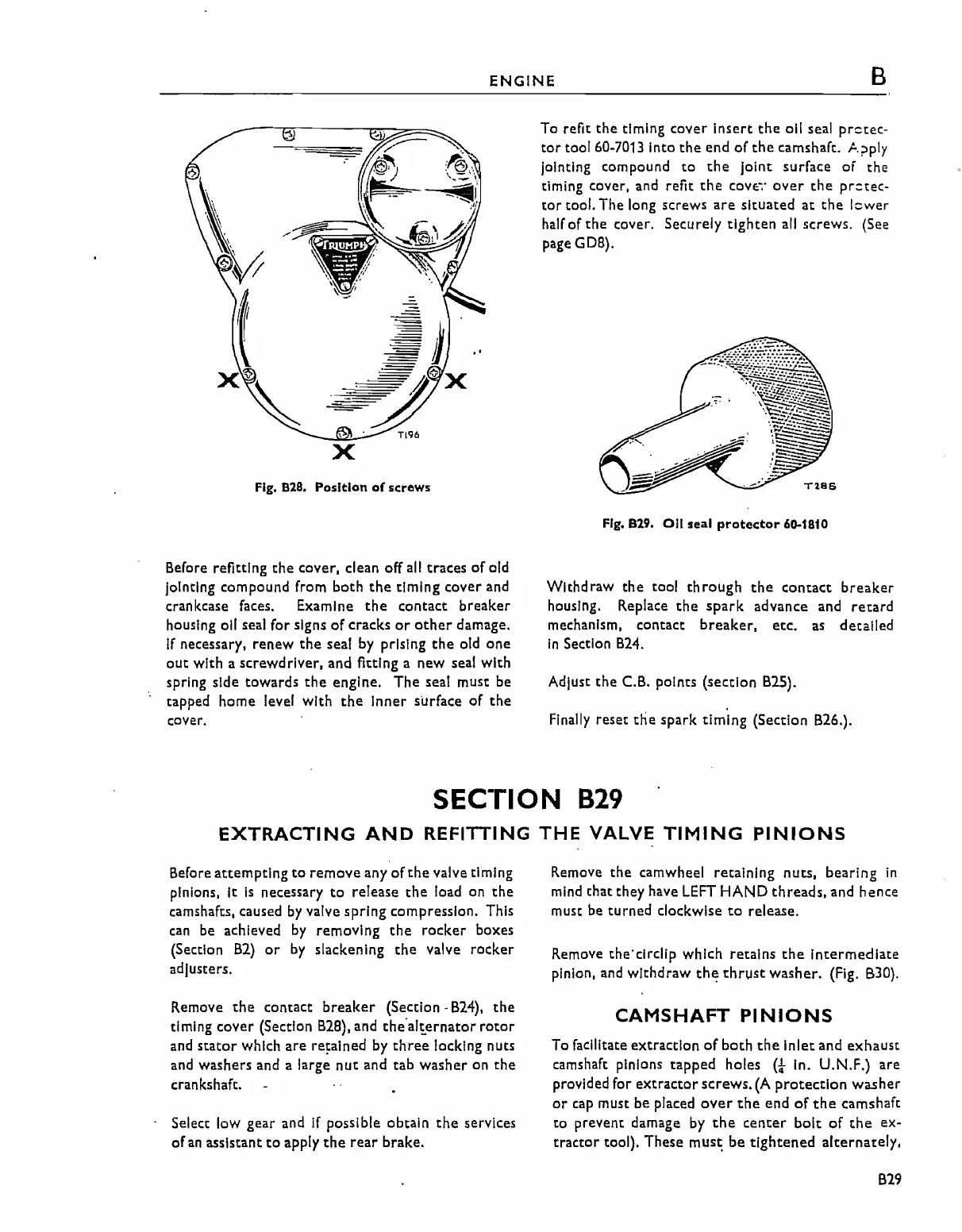

To

refit

the

timing

cover

insert

the

oil seal

prctec-

tor

tool 60-7013 Into

the

end of

the

camshaft. I-.?ply

Jointing compound

to

the

joint

surface

of

the

timing cover.

and

refit

the

COV!;";'

over

the

prctec-

tor tool. The long

screws

are

situated at

the

lcwer

half of

the

cover. Securely

tighten

all

screws. (See

page

GOB).

Fig. 829.

0/1

seal

protector

60-1810

Wlthd raw

the

tool th rough

the

contact

breaker

housing. Replace

the

spark

advance and

retard

mechanism. contact breaker.

etc.

as

detailed

In

Section

B24.

Adjust

the

C.B. points (section B25).

Finally

reset tlie spark timing (Section B26.).

SECTION

B29

EXTRACTING

AND

REFITTING

THE

VALVE

TIMING

PINIONS

Before

attempting

to

remove any of

the

valve timing

pinions.

It

Is

necessary

to

release

the

load on the

camshafts, caused

by

valve spring compression. This

can

be

achieved

by

removing

the

rocker

boxes

(Section

B2)

or

by

slackening

the

valve rocker

adjusters.

Remove

the

contact

breaker

(Section·

B24),

the

timing cover (Section

B2B),

and

theal,ernator

rotor

and

stator

which are re,alned by

three

locking nuts

and washers and a large

nut

and tab

washer

on

the

crankshaft.

Select low gear and

if

possible obtain

the

services

of

an

assistant

to

apply

the

rear

brake.

Remove

the camwheel retaining nuts, bearing

in

mind

that they have

LEFT

HAND

threads.

and hence

must be turned

clockwise

to

release.

Remove the'c1rdlp which retains

the

Intermediate

pinion. and withdraw

the

thrust

washer. (Fig.

B30).

CAMSHAFT

PINIONS

To facilitate extraction

of

both

the

Inlet and

exhaust

camshaft pinions

tapped

holes

(01-

In. U.N.F.) are

provided for

extractor

screws.

(A

protection

washer

or

cap must be placed

over

the

end

of

the

camshaft

to prevent damage

by

the

center

bolt

of

the

ex·

tractor

tool). These

mus~

be

tightened

alternately.

B29

Loading...

Loading...