ENGINE

B

connection

Is

located

under

the

nut

of

the

top

bolt.

Ic

is

most

essential that

this

connection

Is

replaced

on re-assembly using a

new

self locking nut.

The

small

nut

and bolt, holding

the

brake

fluid pipe

to

the engine plate, should also be removed. Unscrew

and

take

off

the

forward

adjuster

'n'Jt on

the

rear

brake pinch rod. This will

enable

the

engine

plate,

complete

with footrest,

brake

pedal and

operating

lever.

to

be lifted clear

of

the

brake

operating

mechanism and

the

frame.

To remove

the

long engine securing

bolt

from

beneath

the

crankcase,

take

off

the

nut

and spring

washer

at

the

left end,

and

withdraw

the

bolt

from

the

right side.

Note

that

on

the

right

side

there

Is

a spacer fitted

between

the

crankcase and

the

frame

tube.

Disconnect

the

horn,

then

remove

It from

the

left

front

engine bracket.

Take

off

the

nut

and washer from

the

left end

of

the

front

engine securing stud, and

withdraw

the

stud,

also

remove

the

bottom

of

the

two

bolts holding

the

left

front

engine

bracket

to

the

frame. Slacken

the

top bolt,

when

the

bracket

can

be

swung

to

one

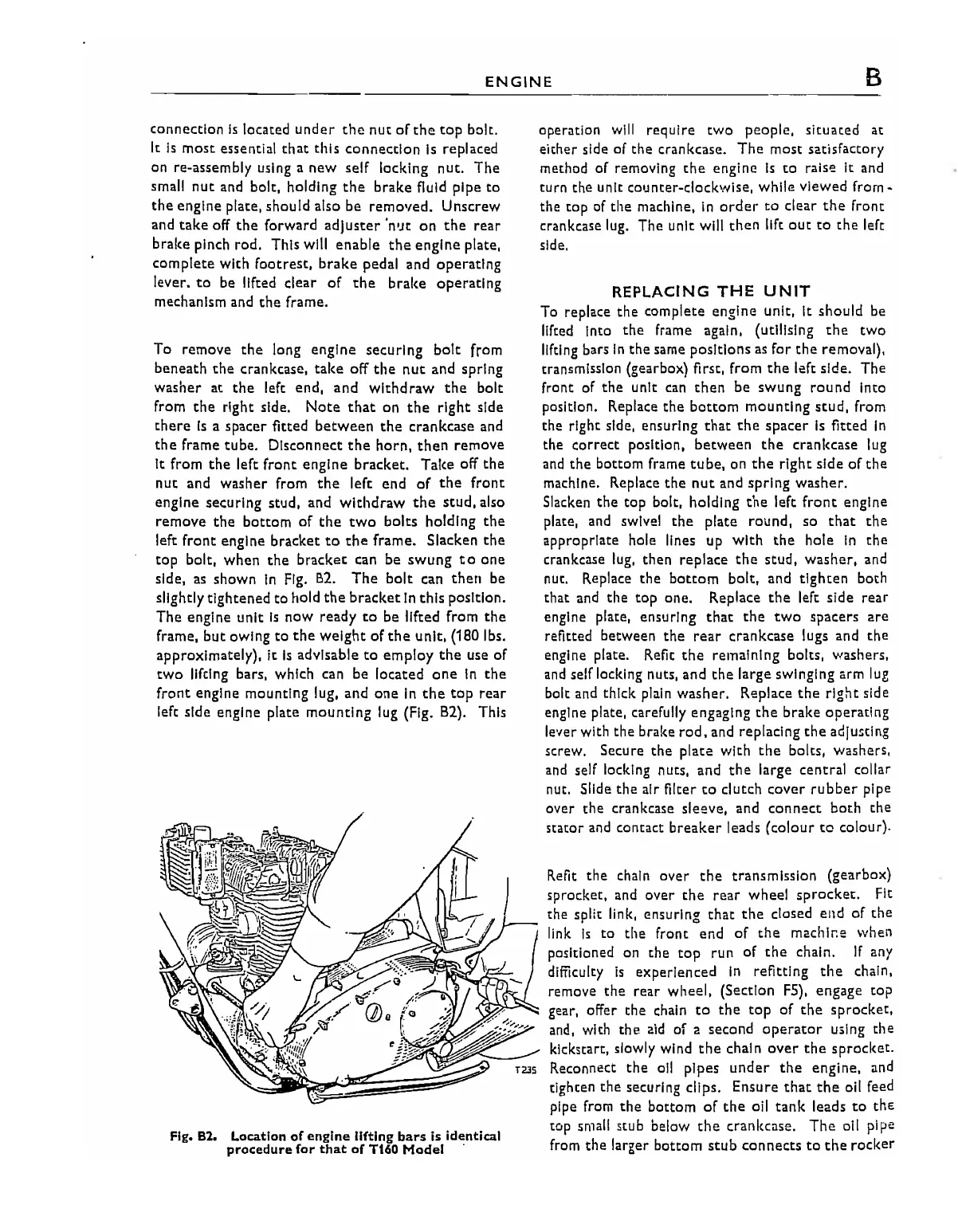

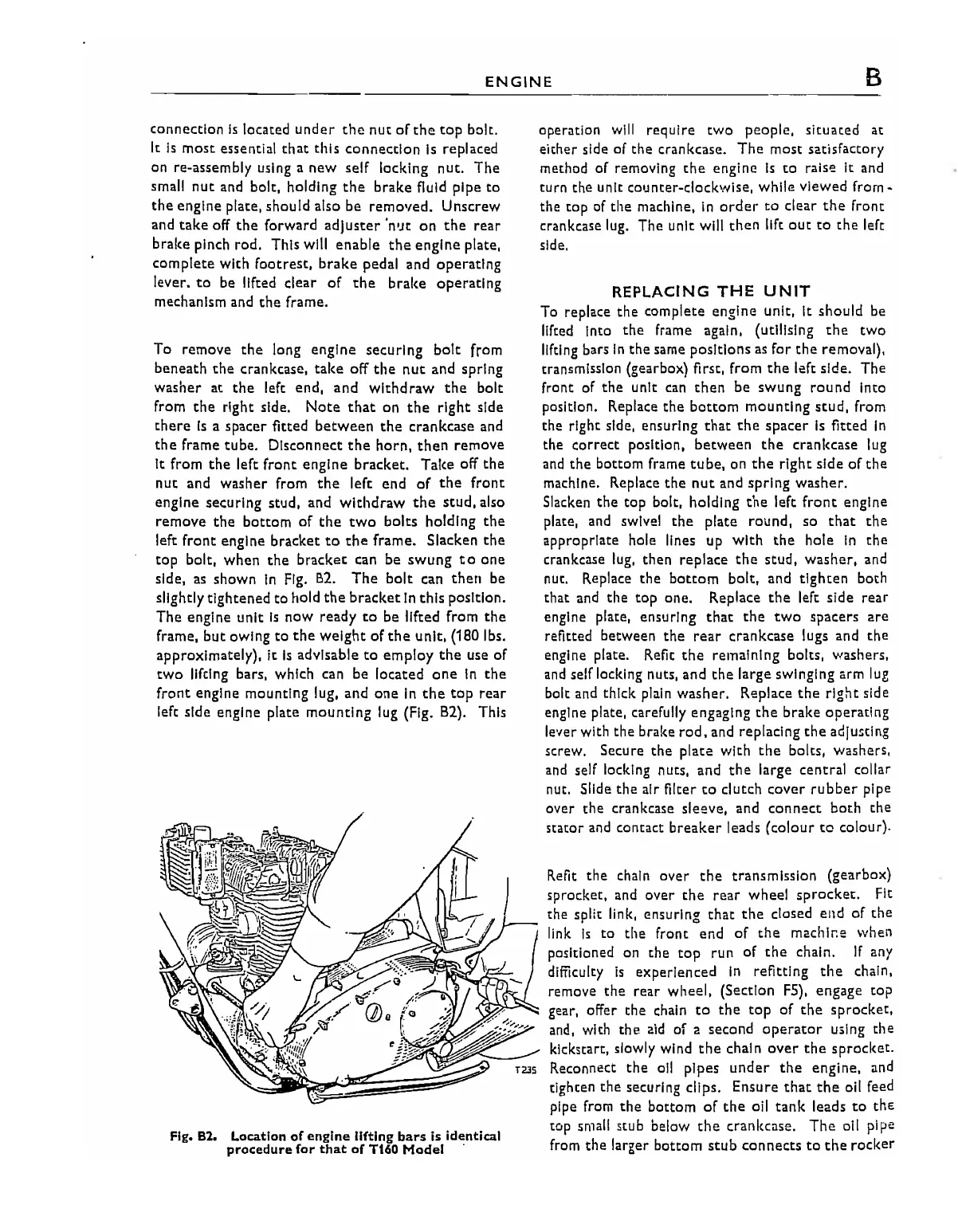

side, as shown

In

Fig.

82.

The

bolt

can

then

be

slightly

tightened

to

hold

the

bracket

In

this

position.

The

engine

unit

Is

now

ready

to

be lifted from

the

frame,

but

owing

to

the

weight

of

the

unit,

(180

Ibs.

approximately), It

Is

advisable

to

employ

the

use

of

two

lifting bars, which can be located

one

In

the

front

engine mounting lug, and

one

In

the

top

rear

left side engine plate

mounting

lug (Fig. 82). This

Fig. 82. Location

of

engine

lifting bars is identical

procedure for

that

of

T160

Model

.

oper:J.tlon

will require

two

people, situated at

either

side

of

the

crankcase.

The

most

satisfactory

method

of

removing

the

engine

Is

to

raise

it

and

turn the unit counter-c1ock\A/ise,

while

viewed

from

...

the

top

of

the

machine,

in

order

to

clear

the

front

crankcase lug. The unit will

then

11ft

oUt

to

the

left

side.

REPLACING

THE

UNIT

To replace

the

complete engine unit, It should be

lifted Into

the

frame again, (utilising

the

two

lifting bars

In

the

same positions

as

for

the

removal),

transmission (gearbox) first, from

the

I.ft

side. The

front

of

the

unit

can

then

be

swung

round

Into

position. Replace

the

bottom

mounting

stud,

from

the right side, ensuring

that

the

spacer

Is

fitted

In

the

correct

position,

between

the

crankcase lug

and

the

bottom frame

tube,

on

the

right side

of

the

machine. Replace

the

nut

and spring washer.

Slacken

the

top bolt, holding

the

left

front

engine

plate, and swivel

the

plate

round,

so

that

the

appropriate hole lines up

with

the

hole

In

the

crankcase lug, then

replace

the

stud,

washer,

and

nut. Replace

the

bottom

bolt, and

tighten

both

that and

the

top

one. Replace

the

left side

rear

engine plate, ensuring

that

the

two

spacers

are

refitted

between

the

rear crankcase lugs and

the

engine plate. Refit

the

remaining bolts, washers,

and self locking nuts, and

the

large swinging arm

lug

bolt and thick plain washer. Replace

the

right

side

engine plate, carefUlly engaging

the

brake

operating

le'ler with

the

brake

rod,

and replacing

the

aclju5tlng

screw. Secure

the

plate

with

the

bolts, washers,

and self locking nuts, and

the

large central collar

nut. Slide

the

air filter

to

clutch

cover

rubber

pipe

over

the

crankcase

sleeve,

and

connect

both

the

stator and contact

breaker

leads

(colour

to

colour).

Refit

the

chain over

the

transmission (gearbox)

sprocket, and

over

the

rear

wheel

sprocket.

Fit

the spilt link, ensuring

that

the

closed end

of

the

link

Is

to

the

front

end

of

the

machlr:e

when

pOSitioned on

the

top

run

of

the

chain.

If

any

difficulty

Is

experienced

In

refitting

the

chain,

remove

the

rear wheel, (Section

F5),

engage top

gear, offer

the

chain

to

the

top

of

the

sprocket,

and, with

the

aid

of

a

second

operator

using

the

klckstart, slowly wind

the

chal n

over

the

sprocket.

Reconnect

the

all pipes

under

the

engine, and

tighten

the

securing clips. Ensure

that

the

oil feed

pipe from

the

bottom

of

the

oil

tank

leads

to

the

tOP

small stub below

the

crankcase.

The

oil pipe

from

the

larger bottom

stub

connects

to

the

rocker

85

Loading...

Loading...