D

TRANSMISSION

(GEARBOX)

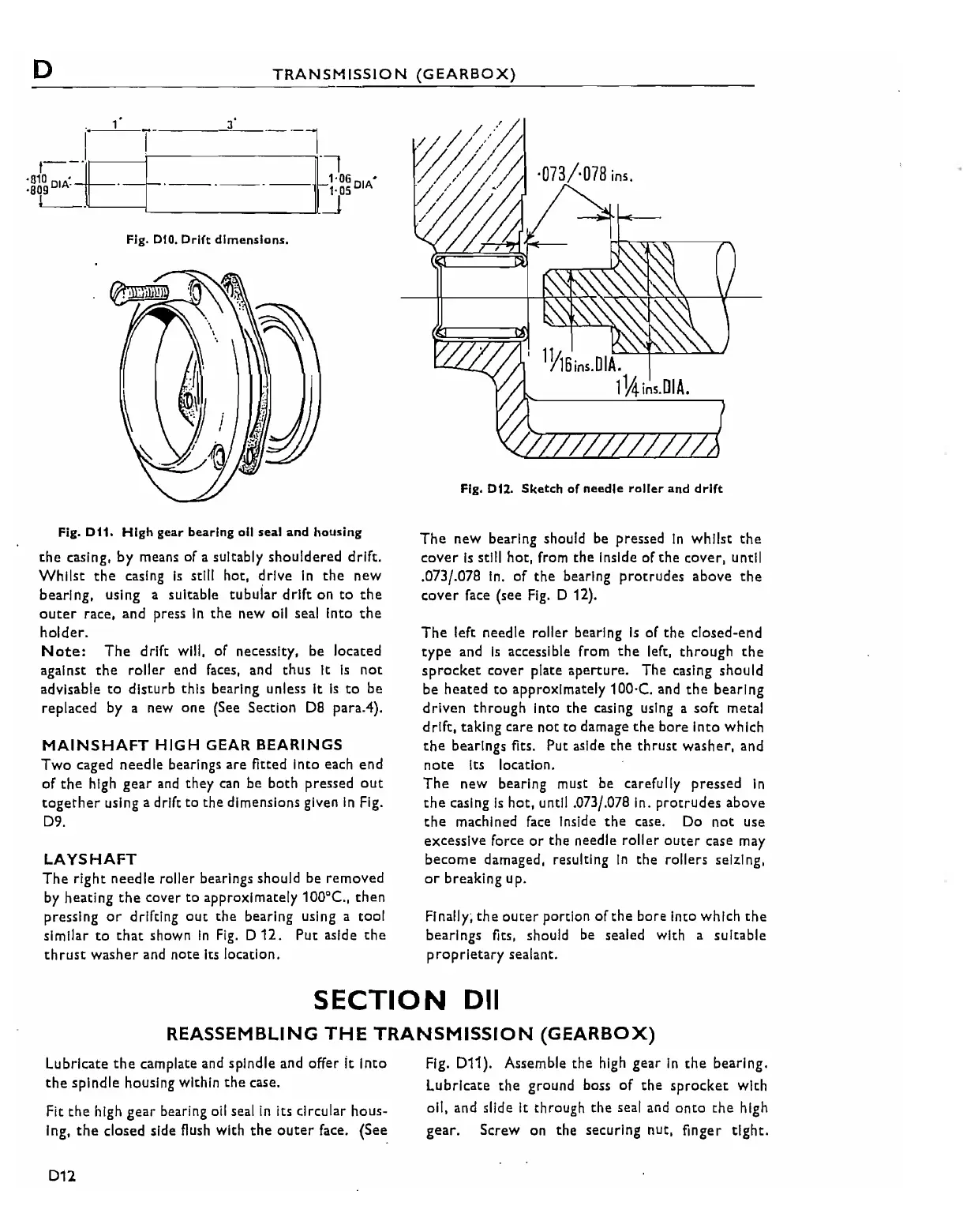

Fig.

OiO.

Drift

dimensions.

Fig.

011.

High

gear bearing all

seal

and

housing

the

casing, by means of a suitably

shouldered

drift.

Whilst

the

casing

Is

stili hot, drive

In

the

new

bearing, using a suitable

tubular

drift

on

to

the

outer

race, and press

In

the

neW

oil seal Into

the

holder.

Note:

The

drift will,

of

necessity, be located

against

the

roller

end faces, and

thus

It

Is

not

advisable

to

disturb this bearing unless It

Is

to

be

replaced by a new

one

(See Section

08

paraA).

MAINSHAFT

HIGH

GEAR

BEARINGS

Two

caged needle bearings are fitted Into each

end

of

the

high

gear

and

they

can be both pressed

out

togerher

using a drift

to

the

dimensions given

In

Fig.

09.

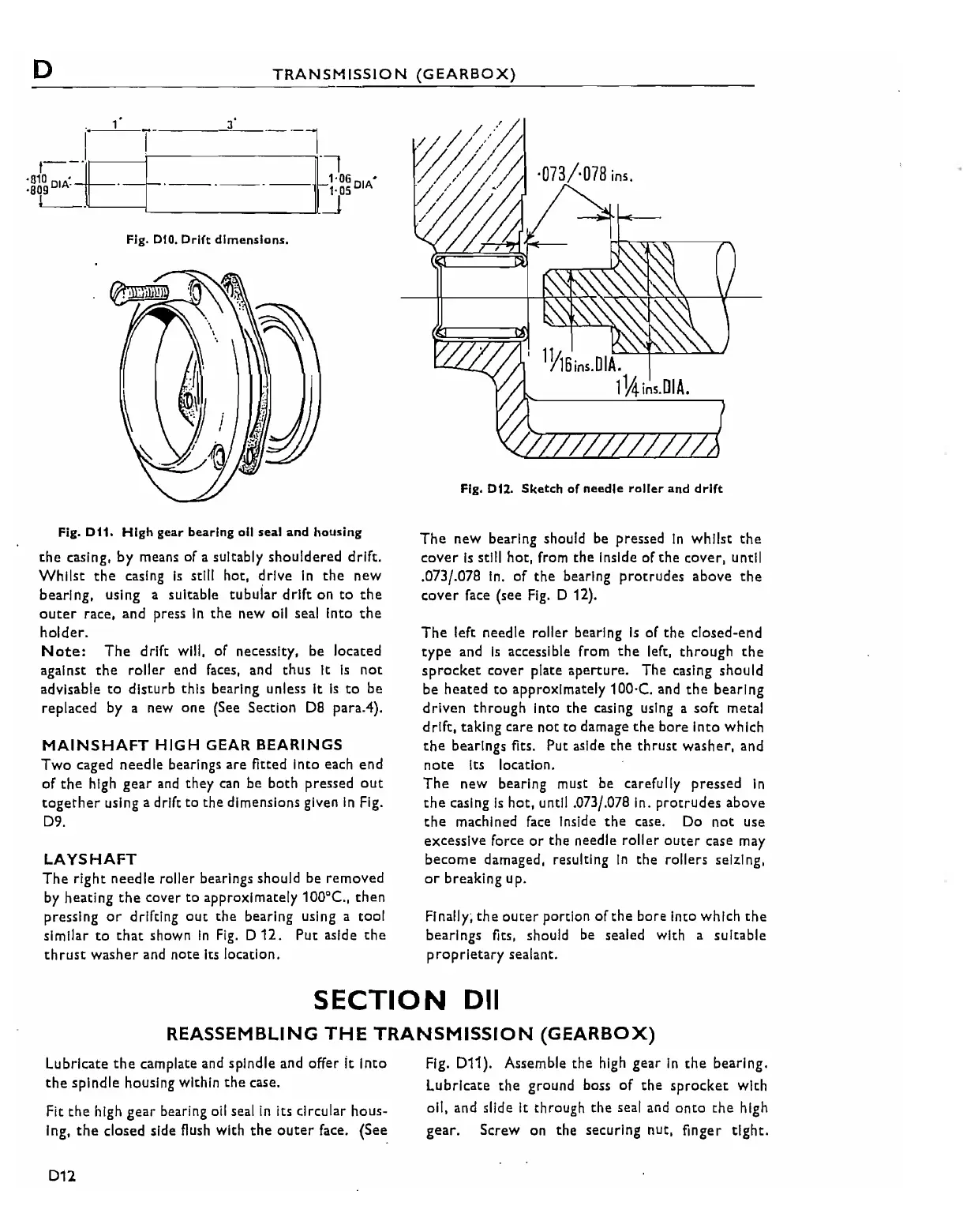

LAYSHAFT

The

right

needle

roller bearings should be

removed

by heating

the

cover

to

approximately 100"C.,

then

pressing

or

drifting

OUt

the

bearing using a

tool

similar

to

that

shown

In

Fig.

D

12.

PUt

aside

the

thrust

washer

and

note its location.

Fig.

012.

Sketch

of

needle

roller

and

drift

The

new bearing should be pressed

In

whilst

the

cover

Is

stili hot, from

the

Inside of

the

cover, until

.073/.078

In.

of

the

bearing

protrudes

above

the

cover

face (see

Fig.

D

12).

The

left needle roller bearing

Is

of

the

closed-end

type

and

Is

accessible from

the

left,

through

the

sprocket

cover plate

.perture.

The casing

should

be

heated

to

approximately 100·C. and

the

bearing

driven

through

Into

the

casing using a

soft

metal

drift,

taking care

not

to damage

the

bore Into which

the

bearings fits.

PUt

aside

the

thrust

washer,

and

note Its location.

The

new bearing must be carefully

pressed

In

the

casing

Is

hot,

until .073/.078 In.

protrudes

above

the

machined face Inside

the

case.

Do

not

use

excessive

force or the needle roller

outer

case may

become

damaged, resulting

In

the

rollers seizing,

or

breaking up.

Finally;

the

outer

portion

of

the

bore Into which

the

bearings fits, should

be

sealed with a

suitable

proprietary

sealant.

SECTION

011

REASSEMBLING

THE

TRANSMISSION

(GEARBOX)

Lubricate

the

camplate and spindle and offer

it

Into

the

spindle

housing within

the

case.

Fit

the

high

gear

bearing

011

seal

In

its circular hous-

Ing,

the

closed side flush with

the

outer

face. (See

012

Fig. 011). Assemble

the

high

gear

In

the

bearing.

Lubricate

the

ground boss

of

the

sprocket

with

011,

and slide It through

the

seal and

onto

rhe

high

gear.

Screw on the securing nut, finger

tight.

Loading...

Loading...