TRANSMISSION

(GEARBOX)

/

0)'

D

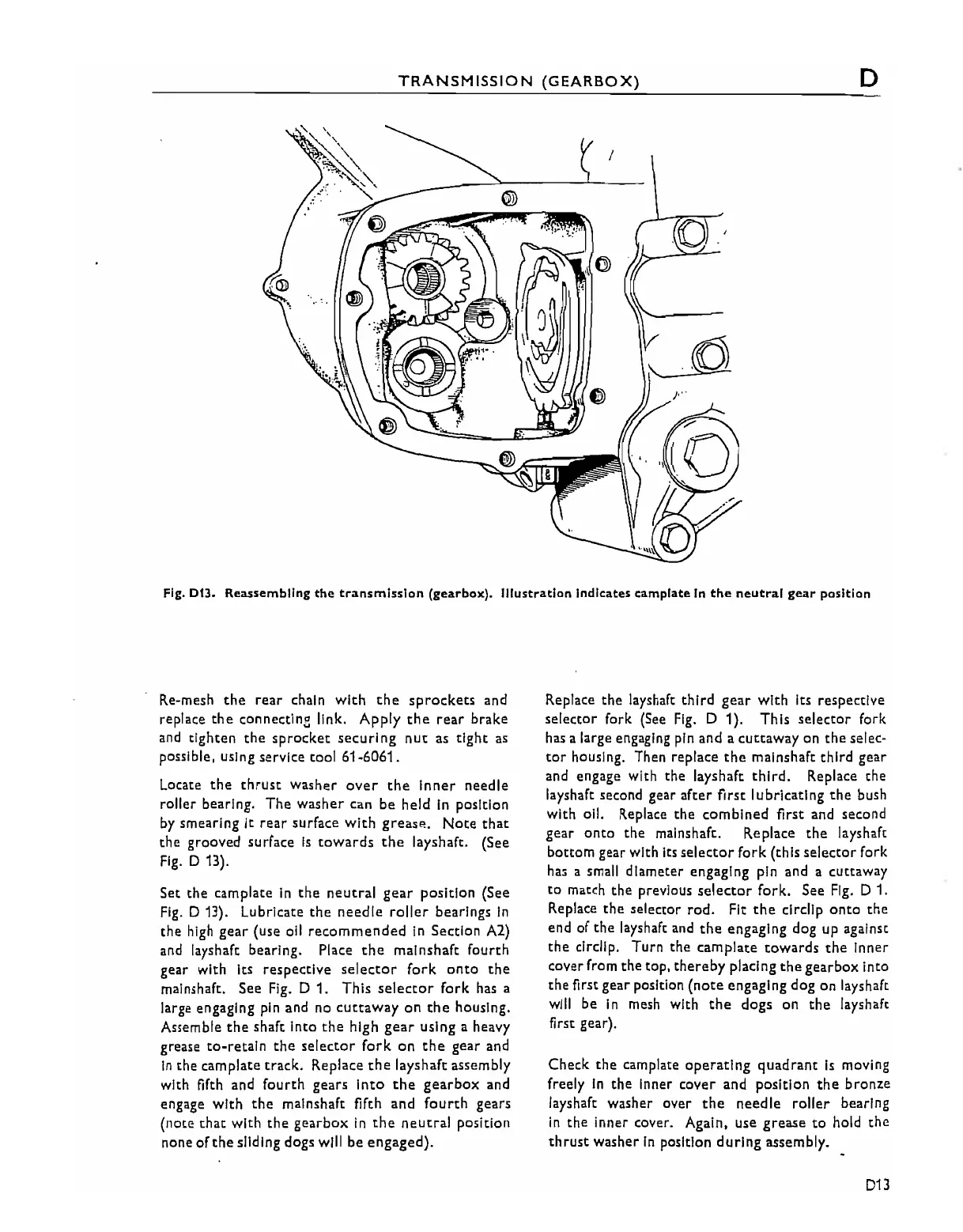

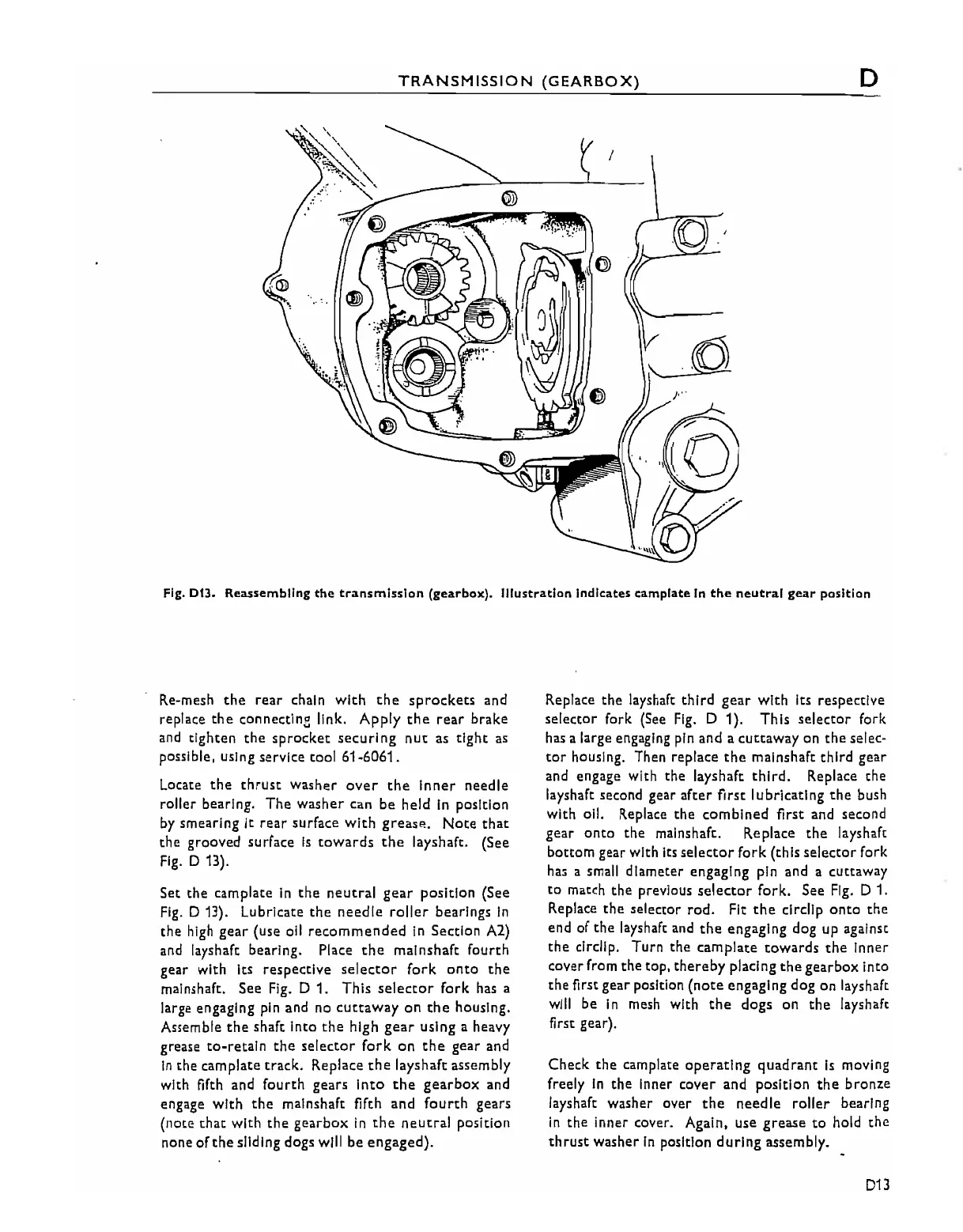

Flg.013.

Reassembling

the

transmission

(gearbox).

Illustration indicates camplate

In

the

neutral

gear

position

Re-mesh

the

rear

chain

with

the

sprockets

and

replace

the

connecting link.

Apply

the

rear

brake

and

tighten

the

sprocket

securing

nUt

as

tight

as

possible, using service tool 61-6061.

Locate

the

thrust

washer

over

the

inner

needle

roller bearing.

The

washer

can

be

held

In

position

by

smearing It rear surface with

grease.

Note

that

the

grooved surface

Is

towards

the

layshaft. (See

Fig.

DB).

Set the camplate

In

the

neutral

gear

position

(See

Fig.

D 13). Lubricate

the

needle

roller

bearings

In

the

high

gear

(use oil

recommended

in Section

AI)

and layshaft bearing. Place

the

mainshaft

fourth

gear with Its

respective

selector

fork

onto

the

malnshaft. See

Fig.

D 1.

This

selector

fork

has a

large engaging pin and no

cuttaway

on

the

housing.

Assemble

the

shaft Into

the

high

gear

using a heavy

grease

to-retain

the

selector

fork

on

the

gear and

in

the camplate

track.

Replace

the

layshaft assembly

with fifth and

fourth

gears

Into

the

gearbox

and

engage

with

the

malnshaft fifth and

fourth

gears

(note that with

the

gearbox

in

the

neutral

position

none

of

the

sliding dogs will

be

engaged).

Replace

the

layshaft

third

gear

with

Its respective

selector

fork (See

Fig.

D 1).

This

selector

fork

has a large engaging pin and a

cuttaway

on

the

selec-

tor

housing. Then replace

the

malnshaft

third

gear

and engage with the layshaft

third.

Replace the

layshaft second gear

after

first

lubricating

the

bush

with oil. Replace

the

combined

first and second

gear

onto

the

malnshaft. Replace

the

layshaft

bottom

gear with Its

selector

fork

(this

selector

fork

h.,

a small diameter engaging pin and a cuttaway

to

match

the

previous

selector

fork.

See

Fig.

D 1.

Replace

the

selector

rod.

Fit

the

clrcllp

onto

the

end of

the

layshaft and

the

engaging dog up against

the

c1rcllp. Turn

the

camplate

towards

the

Inner

coverfrom the top.

thereby

placing

the

gearbox

into

the

first gear position

(note

engaging dog

on

lays haft

will

be

In mesh with

the

dogs

on

the

layshaft

first gear).

Check

the

camplate

operating

quadrant

Is

moving

freely

In

the

Inner

cover

and position

the

bronze

lays haft washer over

the

needle

roller

bearing

in

the inner cover. Again, use

grease

to

hold the

thrust

washer

In

position

during

assembly.

D13

Loading...

Loading...