D

TRANSMISSION

(GEARBOX)

Fig.Of4.

Refitting

the

gearbox

Inner

cover

Using a

pressure

011

can,

lubricate

all

the

moving

parts

In

the

gearbox. Check

the

condition

of

the

gasket which fits between

the

crankcase and

the

Inner cover.

Place

It

In

position with a smear

of

grease.

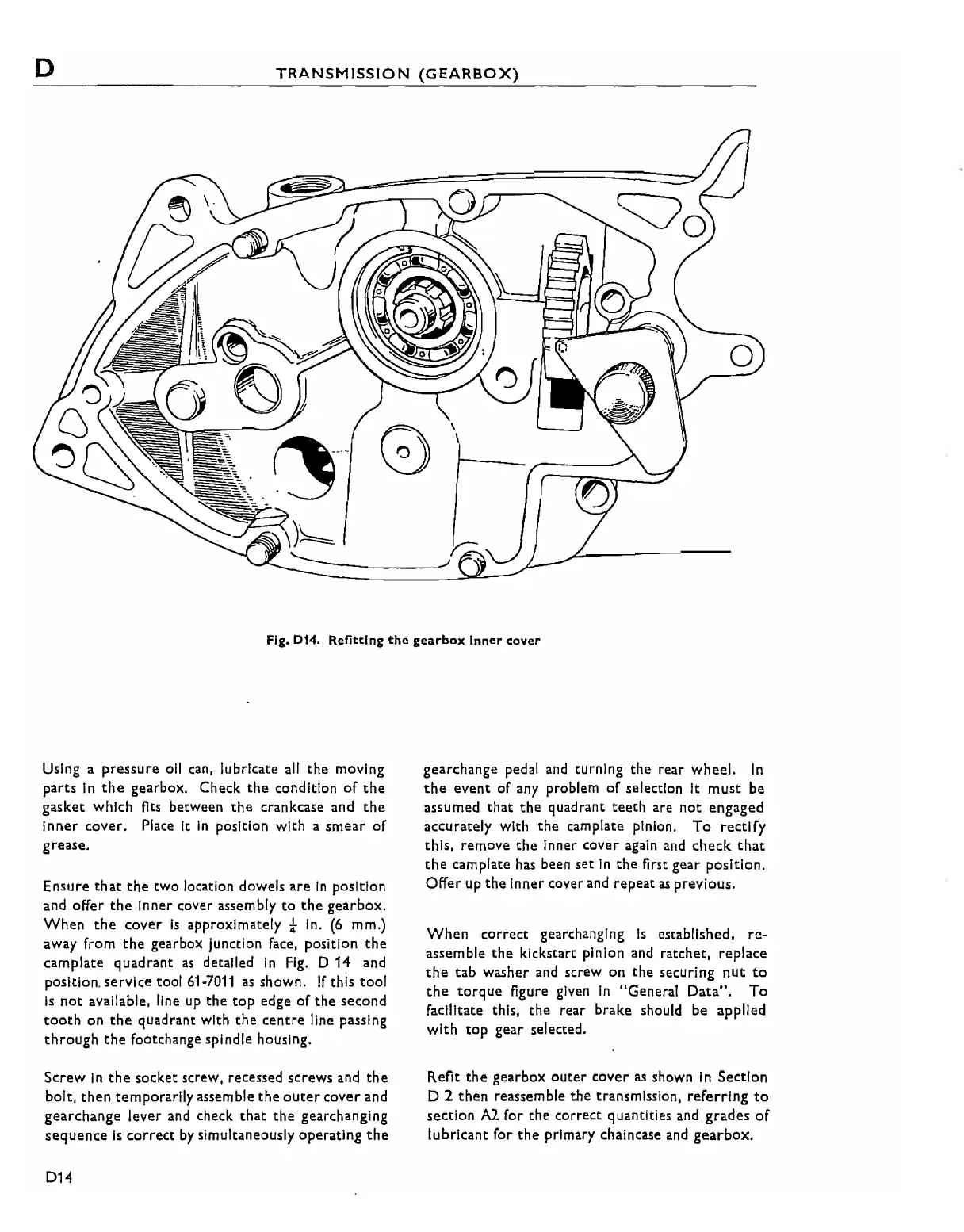

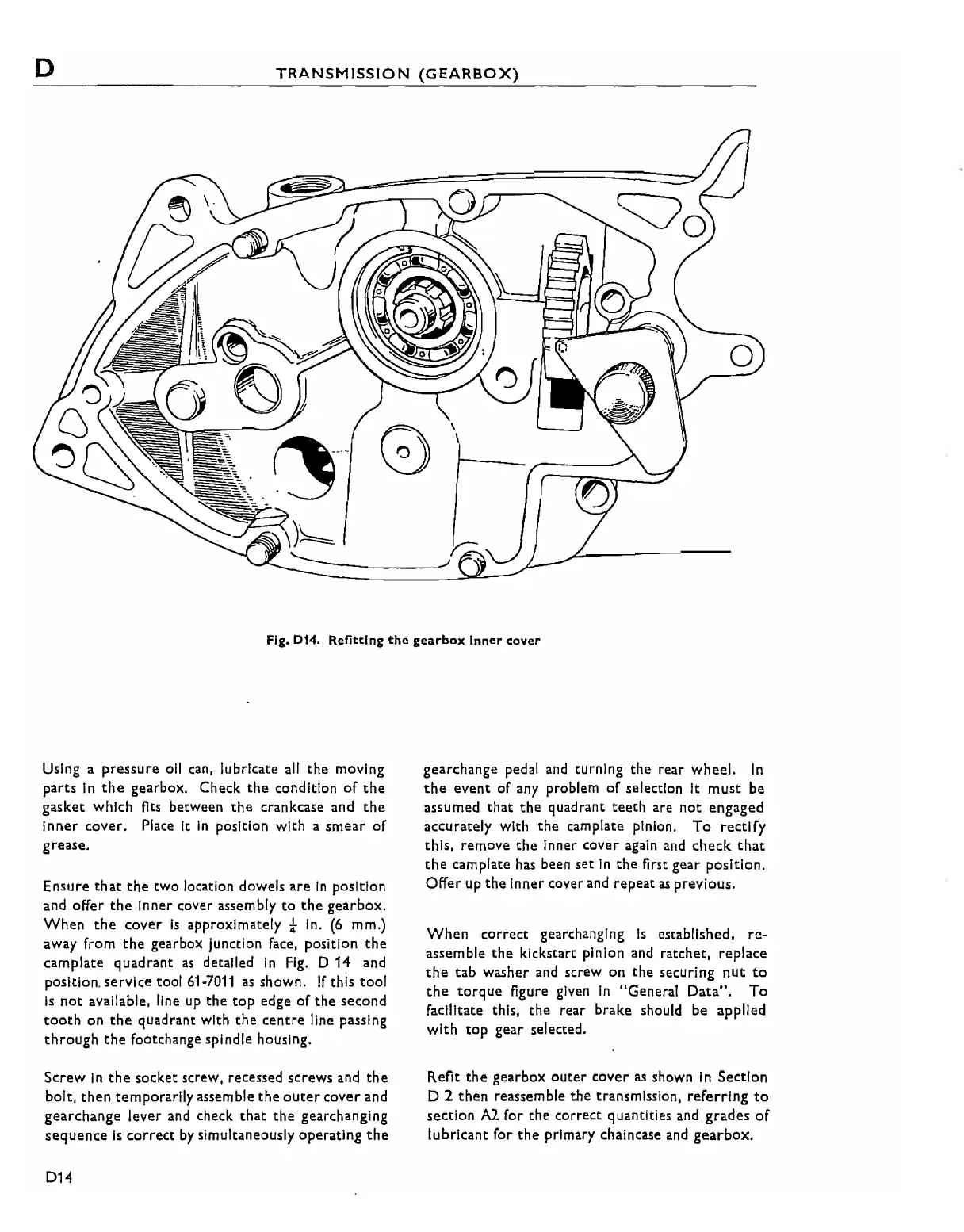

Ensure

that

the

two

location

dowels

are

In

position

and offer

the

Inner cover assembly

to

the

gearbox.

When

the

cover

Is

approximately

tin.

(6

mm.)

away from

the

gearbox junction face, position

the

camplate quadrant

as

detailed

In

Fig.

D

14

and

position. service tool

61·7011

as

shown.

If

this

tool

Is

not

available, line

up

the

top

edge of the second

tooth

on

the

quadrant with

the

centre

line passing

through

the

footchange spindle housing.

Screw

In

the

socket screw, recessed screws

and

the

bolt,

then

temporarily assemble

the

outer

cover and

gearchange lever and check

that

the

gearchanglng

sequence

Is

correct

by

simultaneously operating

the

D14

gearchange pedal

and

turning the rear

wheel.

In

the

event

of any problem of selection It

must

be

assumed

that

the

quadrant

teeth

are

not

engaged

accurately with the camplate pinion.

To

rectify

this,

remove

the Inner cover again

and

check

that

the

camplate

has

been set

In

the

first gear position.

Offer

up

the

Inner

cover

and

repeat

as

previous.

When

correct gearchanglng

Is

established, re-

assemble

the

klckstart pinion and ratchet. replace

the

tab washer

and

screw

on

the

securing

nut

to

the

torque

figure given

In

"General

Data".

To

facilitate this, the rear brake should be applied

with

top

gear selected.

Refit

the

gearbox

outer

cover

as

shown

In

Section

D 2

then

reassemble the transmission,

referring

to

section

IV..

for the correct quantities

and

grades

of

lubricant for

the

primary chaincase and

gearbox.

Loading...

Loading...