136

FNC

07

W D T P

1

2

M

3

○ ○ ○○

A PLC is provided with the WDT (Watch Dog Timer), which is used to monitor operation condition of the PLC system.

By way of the WDT to monitor the process, when the PLC's CPU runs abnormally, that will command the PLC to stop

operation and turn all external output “OFF”. This system achieves the protection purpose.

(2) Use the MOV instruction to change the content value of D9000.

To adopt this approach, it should be noted that at the first Scan Time of the PLC (from “STOP” to “RUN”),

the value of WDT timer is still 200 ms. The program below can be used for the solution where necessary.

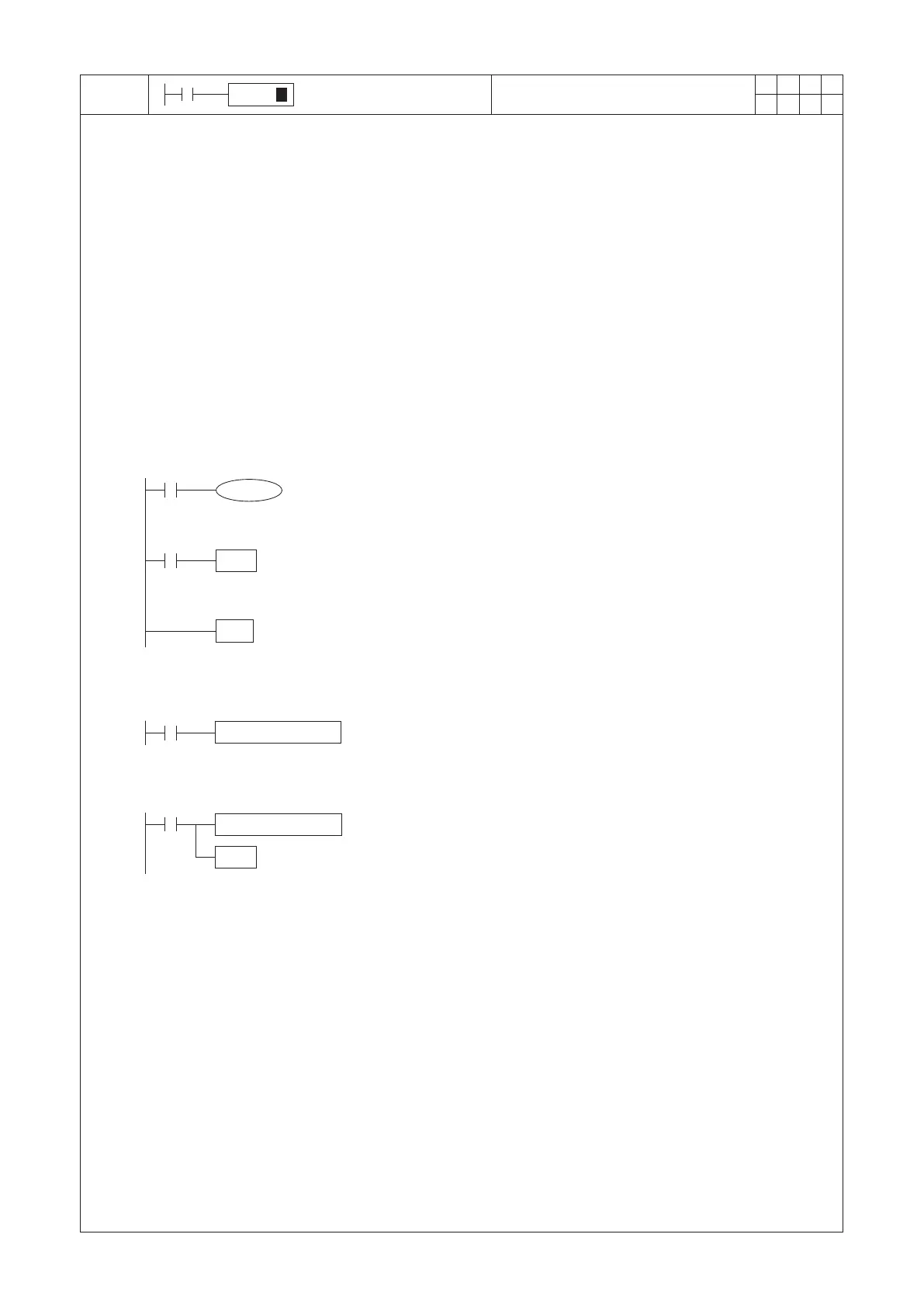

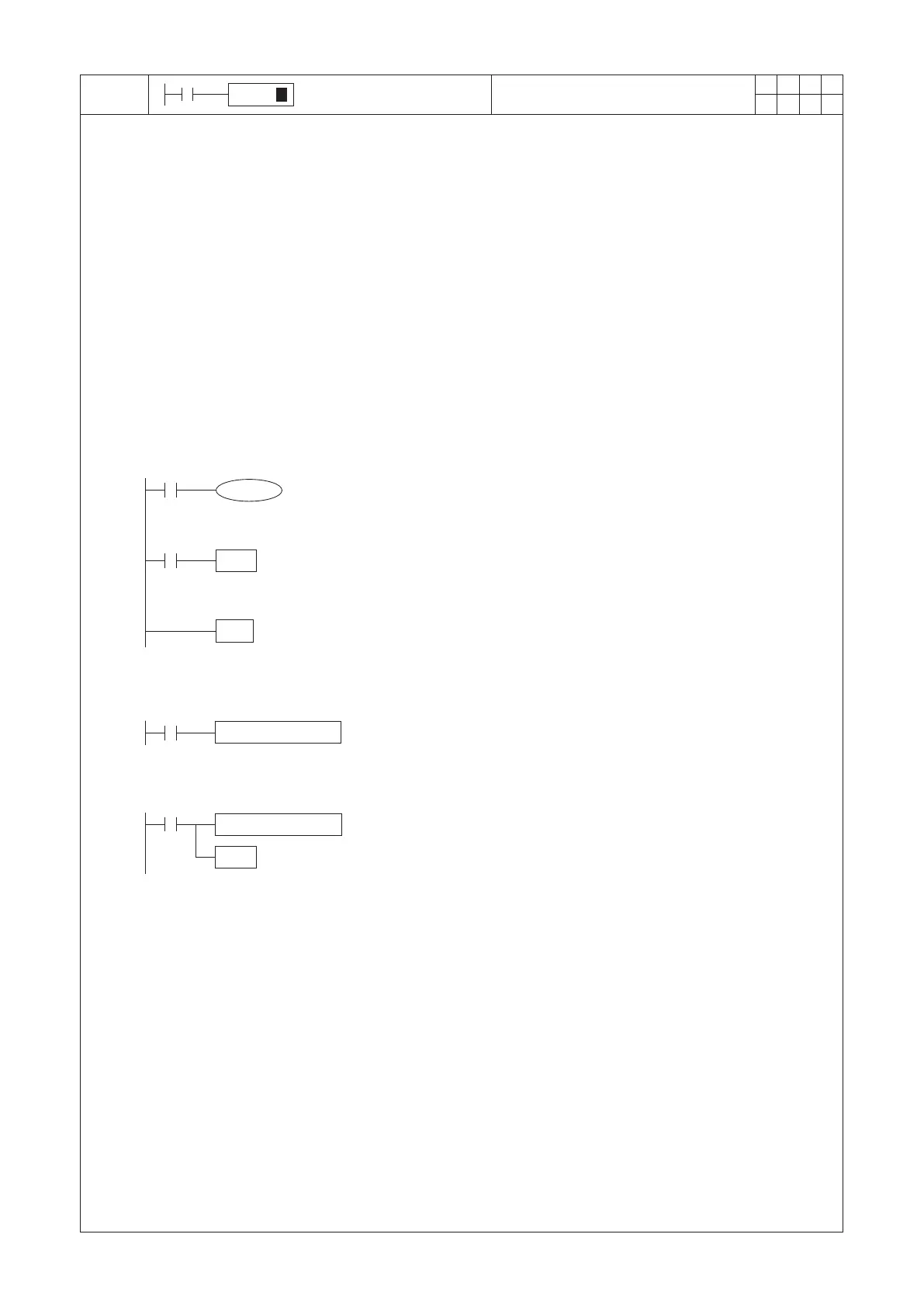

WDT

M9000

〜

END

〜

MOV K300 D9000Set the WDT to be a timer of 300 ms

M9002

MOV K300 D9000

The explanation of the WDT (Watch Dog Timer):

M9002

WDT

MOV K300 D9000

The WDT instruction reverts the current value of the WDT timer to the content value of D9000

in the middle of the program.

Watch Dog Timer Refresh

The WDT is a hardware timer with 200 ms. set value. When PLC=“STOP” → “RUN”, the value of WDT will reload from

the content value of Special Register D9000 and while the initial value of D9000 is “200”.

This timer is counting downward by a timing unit of 1 ms. If the current value reaches “0”, the WDT will determine

that there is a system trouble. It forces the PLC to stop operation and turn all external output “OFF” to achieve the

protection purpose.

When the system operates normally, PLC will revert its WDT timer before it executes the beginning of program

(STEP 0).

There are two reasons to activate WTD (Watch Dog Timer) function:

1. Any trouble is happened in the PLC system and WDT performs the protection function.

2. If the time of program execution is too long, the program's Scan Time more than the content value of D9000,

it will trigger the protection function of WDT. Below are two approaches to improve the foregoing situation and

make the system operate normally.

For the second cause, here provide two solutions:

(1) Insert WDT instruction into the program, because WDT instruction will revert the current value of WDT.

Loading...

Loading...