4-7-2 Filling Bottles

ON : Down

OFF: UP

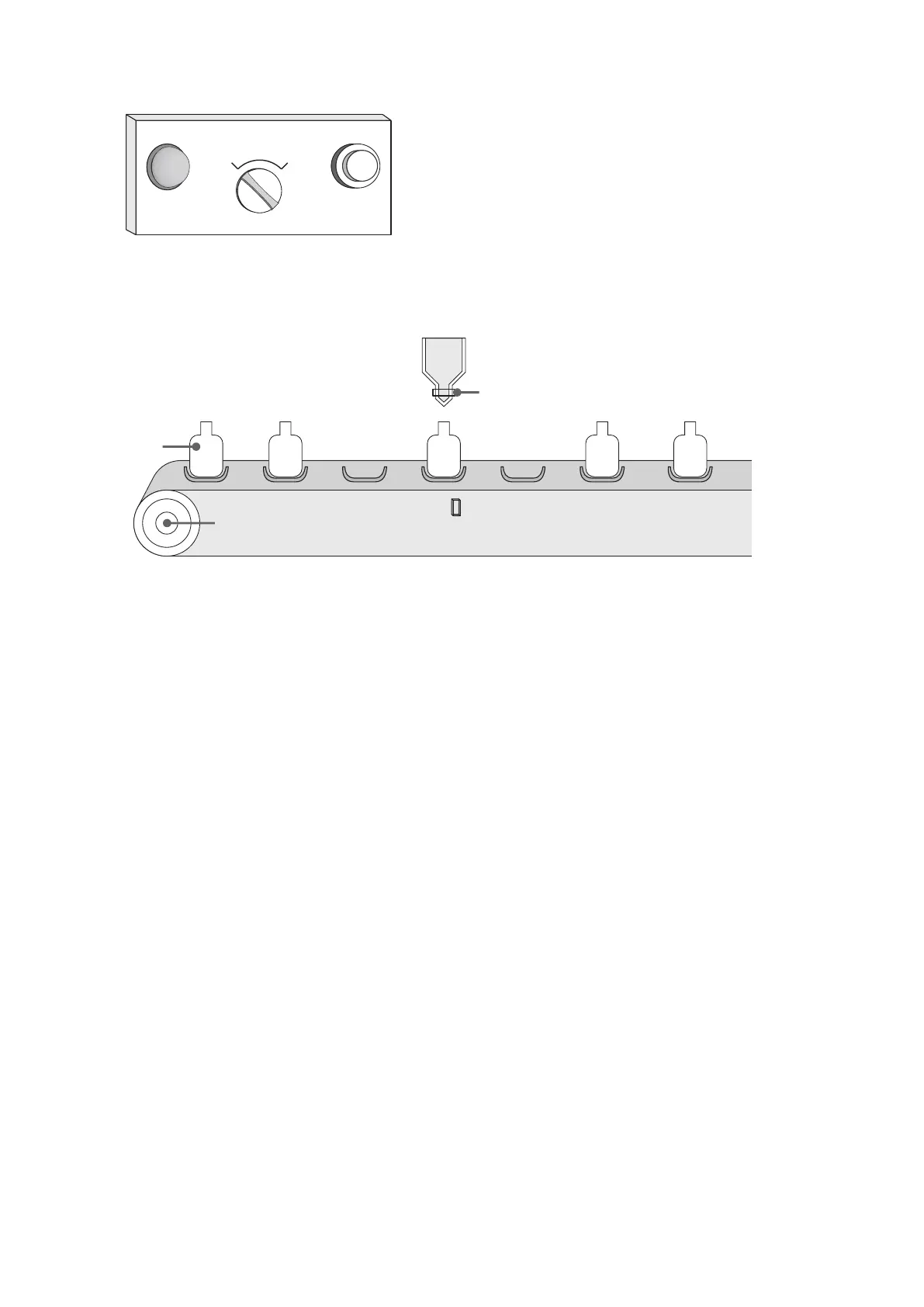

Nozzle valve Y3

Juice

X0Y0 X2

107

Repeat

Single Run

READY

START

OFF

:

ON

:

Repeat

Single Run

Bottle

The lifter of nozzle

is driven by Y2:

ON : Open valve to ll up

OFF : Close valve

Bottle inspector X1

Conveyor motor Y1

Function Description of Bottle Filling:

There is a control panel next to the bottle lling machine. The READY indicator on the front of panel that indicates at the

standby status. Use the START button to activate the device and the mode selector switch to choose from a single run

or repeated operation.

(1) When the machine is ready to start operation, the READY indicator is ON.

(2) Press the START button and the conveyor motor starts to rotate. When the bottle inspector detects that the bottle

has reached the right position, the motor stops rotating.

(3) When the nozzle lifter is ON, the nozzle going down. It is determined that in 3 seconds the lling nozzle will reach the

position.

(4) The injection valve opens and starts lling. In 5 seconds, the lling will be completed and the valve will be closed.

(5) When the valve of the lling nozzle is OFF, the lling nozzle rises. It is determined that in 3 seconds the lling nozzle

will rise to reach the position.

(6) The lling process is completed. At this point, it returns to the state of standby if at the “Single Run” mode; it starts the

conveyor motor again and processes the next bottle ll up if at the “Repeat” mode.

The two drawings below display using the (a) SFC or (b) STL in writing the program, in order to comparison reference.

Loading...

Loading...