3-6 The MC and MCR Instructions

MC

(MASTER CONTROL)

MCR

(MC RESET)

N0〜 N7

N0〜 N7

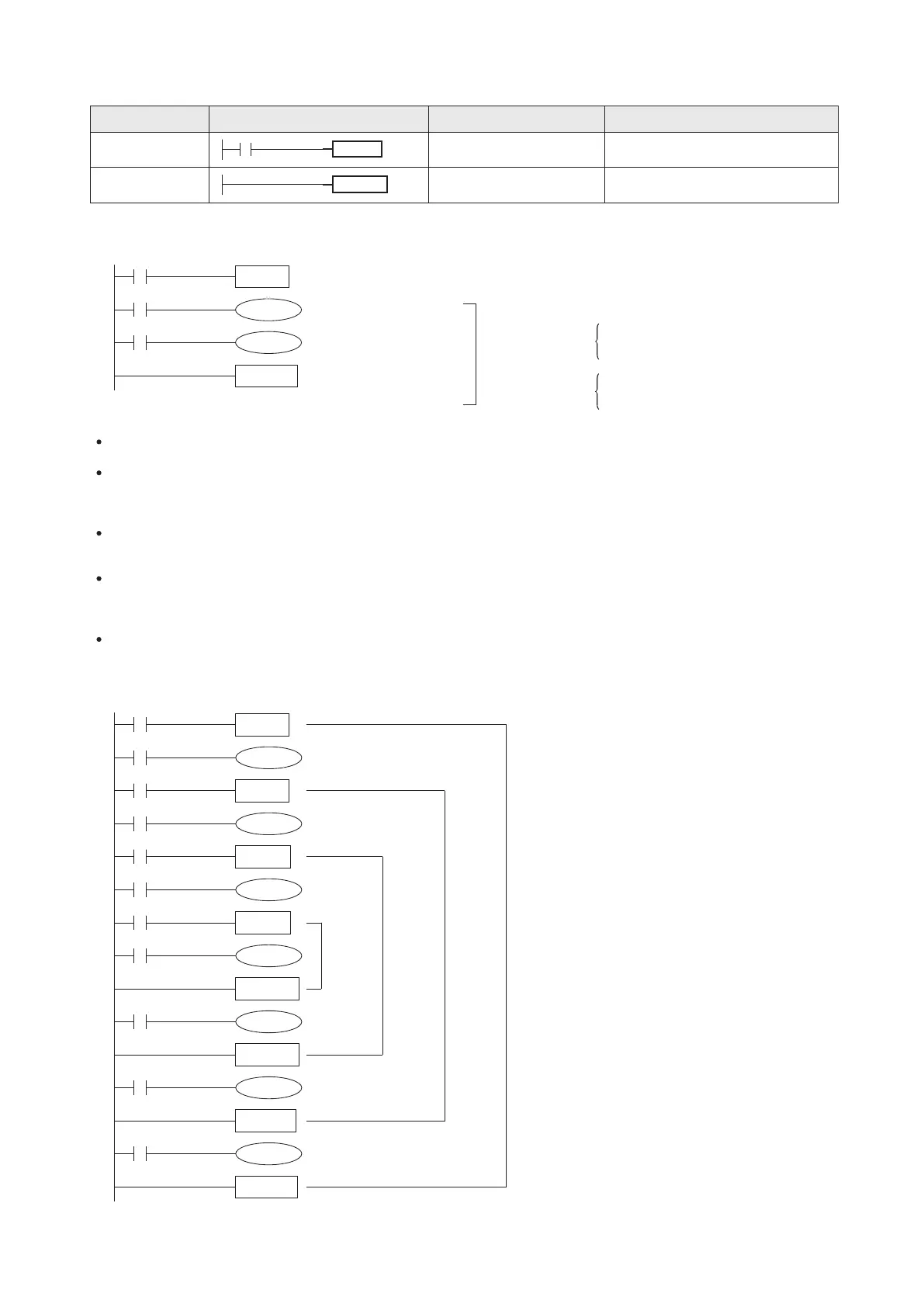

MC N0

MCR N0

MC

LD

OUT

LD

OUT

MCR

LD X0

N0

X1

Y20

M10

Y21

N0

If X0=ON then

If X0=OFF then

Y20=OFF

Y21=OFF

X0

X1

M10

MC N0

Y20

Y21

MCR N0

85

Denote the start of a master control block

Denote the end of a master control block

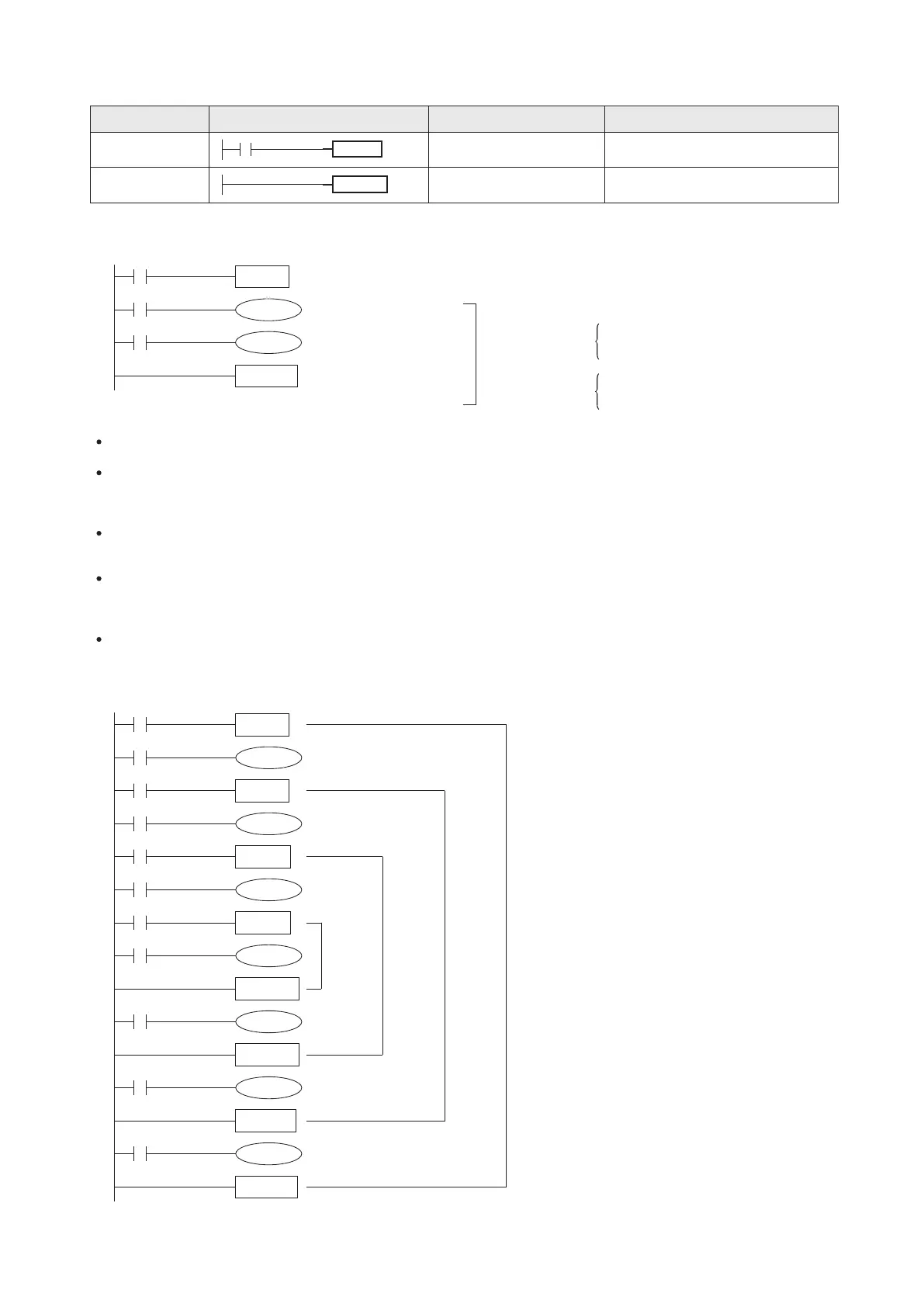

X0

X1

X21

X2

X22

X3

X23

X24

X25

MCR N2

MCR N1

Y26

MCR N0

Y25

MC N1

Y21

MC N2

Y22

MC N3

Y23

MCR N3

Y24

X20

Y20

X26

MC N0

The X0 is the condition contact

Status of Y20 = Status of X1

Status of Y21 = Status of M10

When the condition contact X0 is “ON”, all instructions between the MC and MCR instructions will be executed normally.

When the condition contact X0 is “OFF”, all instructions between the paired MC and MCR instructions will NOT be

executed, also all ordinary Timers and the coils which is driven by the OUT instruction will be reset; but the Retentive

Timers, Counters and the status of coils which is driven by the SET / RST instruction will be kept.

Use the MC instruction to shift the bus line (the Initial logical operation) to a point behind the conditional contact and then

use the paired MCR instruction to return to the original bus line.

A master control block allows to contain another master control block inside, which is to form a nest level. This structure

at the most can have 8 levels N0~N7. The top nest level shall be the N0, and followed by N1, N2..., so the most inner level

shall be the N7.

A program example with a multiple nest levels structure is shown below:

th

4 level

rd

3 level

nd

2 level

st

1 level

Mnemonic Devices Function Format

Ladder Diagram

Instruction List

Ladder Diagram

Become a master control block which is controlled by the

X0.

Loading...

Loading...