371

7-3-2 VS Computer Link Slave

RS- 485

VS

protocol

RS- 232

VS

protocol

When the VS PLC’s communication port has been set to the application type of the “VS Computer Link Slave”, the

human-machine interface (HMI) or supervisory control and data acquisition system (SCADA) can access the VS PLC’s

data through the “VS Compurter Link Protocol” (hereby referred to as VS Protocol).

A computer or HMI through the “VS Protocol” could communicate with the VS PLCs. The HMI or SCADA supplier base

on the “VS Protocol” to compile its driving programs, by way of that communicates with VS PLC’s to construct a

monitoring area network.

VS

protocol

VS

Slave

VS

Slave

VS

Slave

VS series

PLC

VS series

PLC

VS series

PLC

HMI

or

SCADA

HMI

or

SCADA

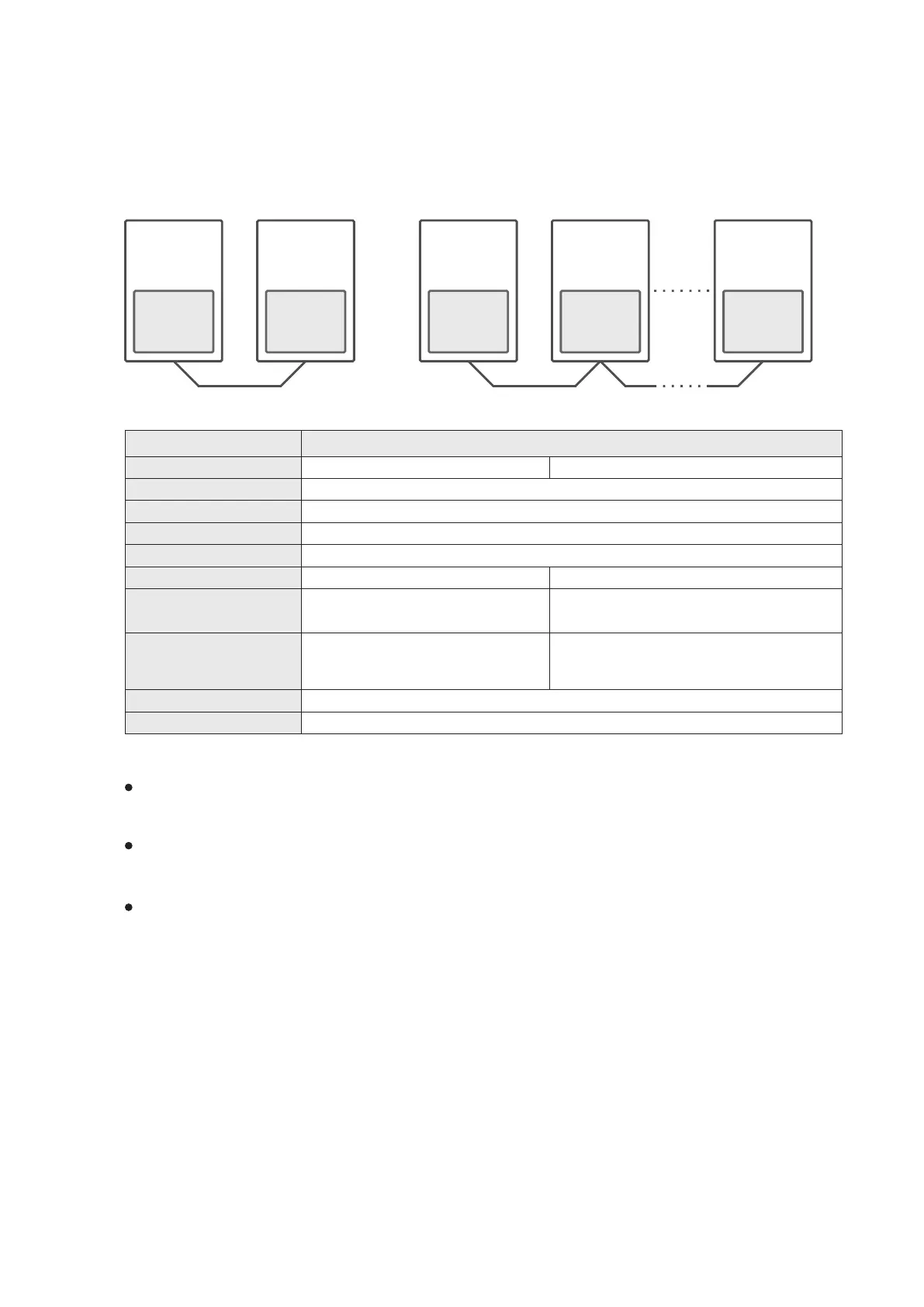

Selectable: 300/600/1200/2400/4800/9600/19200/34800/57600/115200 bps.

VS Compurter Link Protocol (hereby referred to as VS Protocol)

Half-duplex

Bits-per-character: 8 bits; parity check: None; stop bit: 1 bit

Up to 15 meters

Non-isolated: 50 m.; Isolated: 1 km.

1 Slave station only

Max. 255 stations (For more than 32, add

repeater(s) in the circuit is required)

CP2~CP5: VS-D232-EC

CP3, CP5: VS-D52A-EC(CH2)

CP1: Main Unit built-in

CP2~CP5: VS-D485-EC, VS-D485A-EC

CP2, CP4: VS-485-EC, VS-485A-EC, VS-D52A-EC(CH1)

CP3, CP5: VS-ENET-EC(CH2)

VS Series PLC (including VS1, VS2, VSM and VS3)

All the X, Y, M, S, T, C, D, R are included

Item

Specification

RS-485RS-232Communication Interface

Communication Protocol

Commection Method

Communication Paramete

Baud Rate

Distance

No. of Slave Stations

Linking Equipment

Available Model

Transferable Device

The VS PLC will respond to the communication requirement by any device (such as a computer, HMI,...) if that follows

the particular “VS Compurter Link Protocol” to give correct command. For the detail of the VS Protocol, please refer

to the section “7-4 VS Series PLC Communication Protocol” for details.

Usually, HMI or SCADA supplier base on the “VS Compurter Link Protocol” to compile driving program. Therefore, the

HMI or SCADA user just needs to select the correct communication type when planning the system, so that can

communicate with VS PLCs to construct a monitoring area network.

Some software or HMI may not be equipped with the driving program of the VS Series PLC. In this case, the

“MODBUD Slave” application type can be used to connect them. Please refer to the section “7-3-5 MODBUD Slave”

for details.

Loading...

Loading...