418

Press the “Default” button, that will reset the set contents to the default values about this axis.

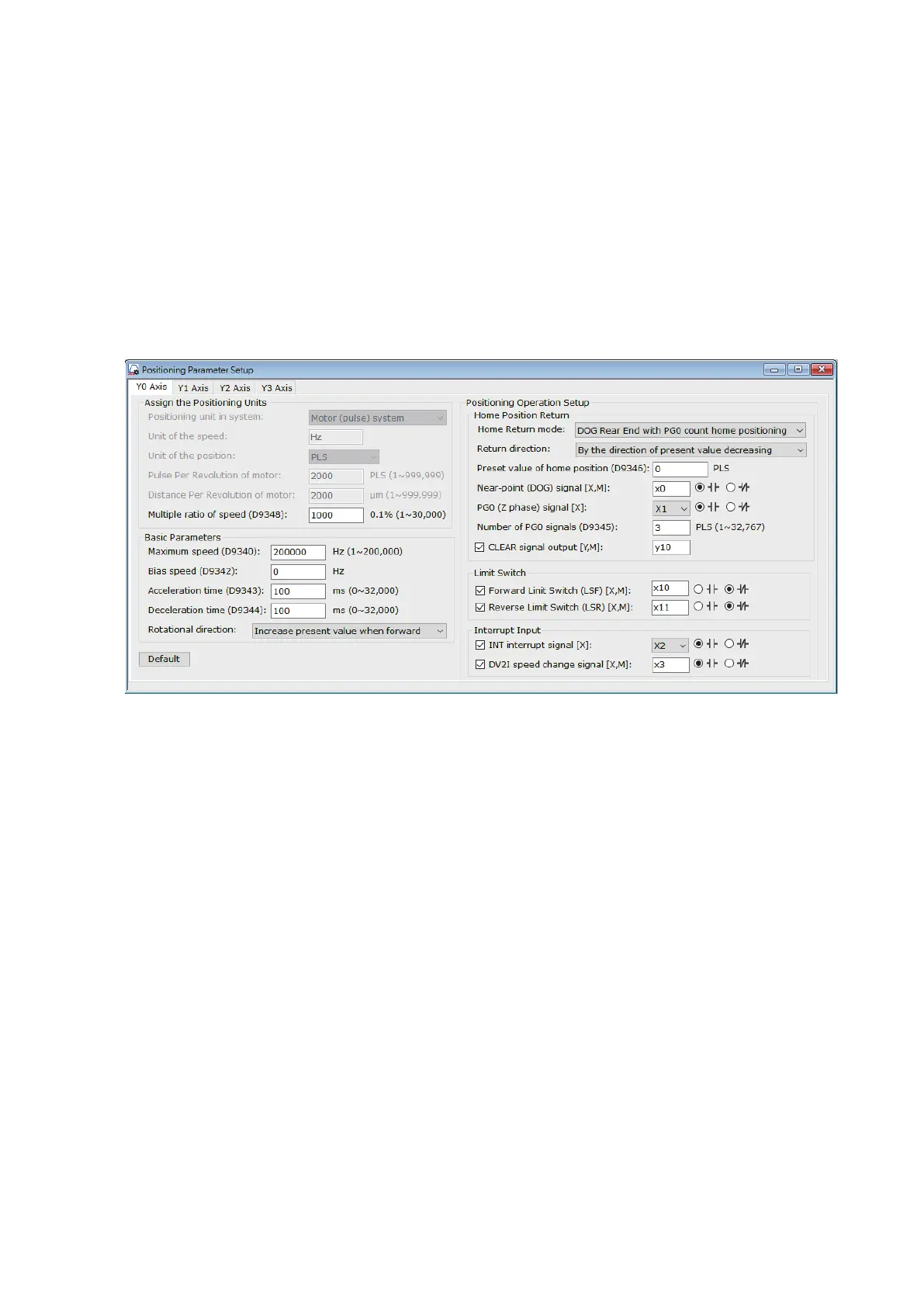

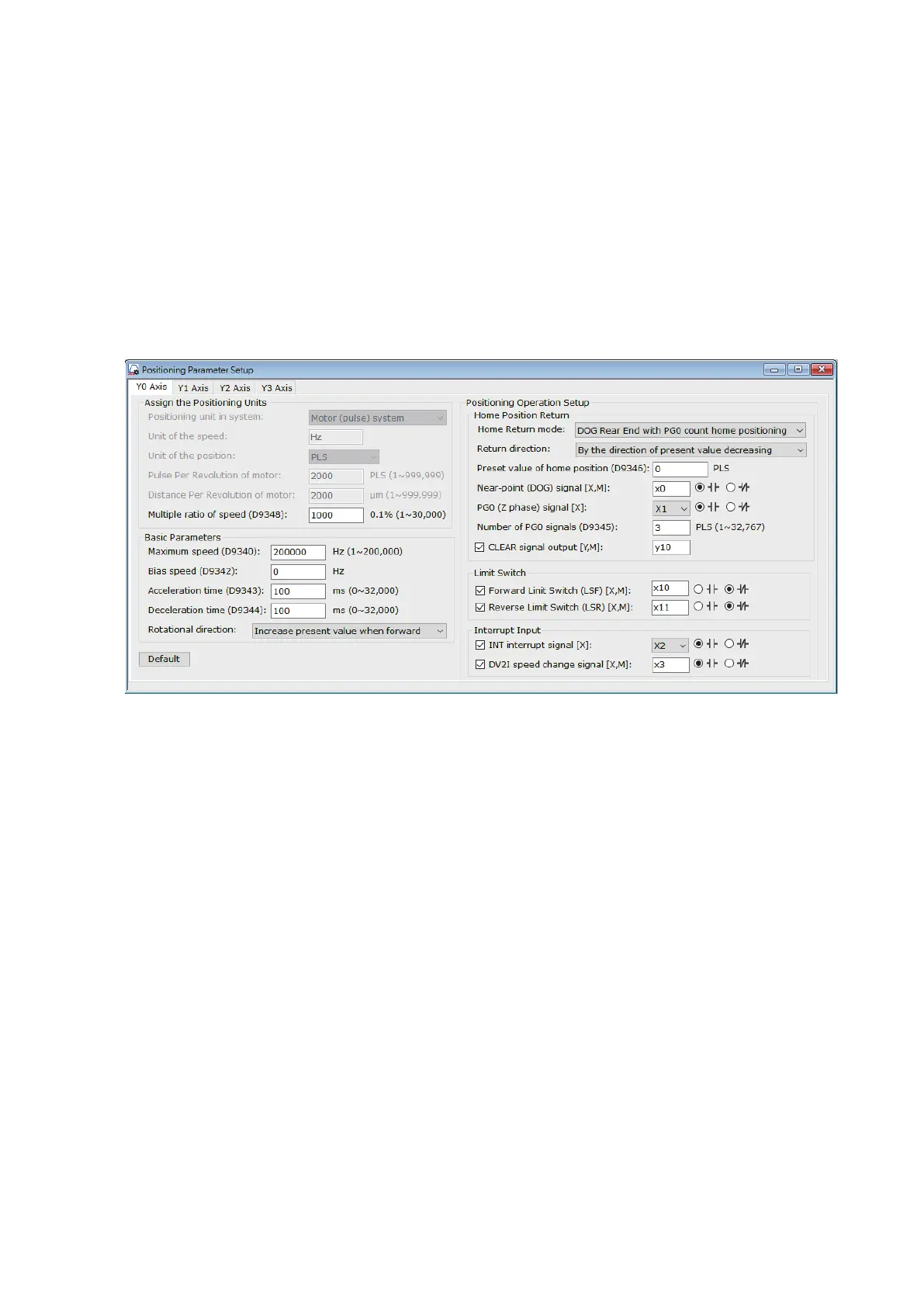

8-1 Positioning Parameter Setup

The Ladder Master S provides the Positioning Parameter Setup function to simplify the VS series PLC’s process of

setting relevant parameters. The contents of positioning parameters will be written onto the PLC with the project. After

that, only the appropriate positioning control instructions are needed to complete the positioning control work easily.

In the most of cases, the Positioning Parameter Setup function can satisfy application requirements.

However, during the operation, some specic applications may need to change related parameters. Thus, a part of the

positioning parameters are not only preset by the setting of the parameter setup page, but also can make changes at

relevant special registers via the user program.

When PLC’s power is turned from “OFF” to “ON” and the project had been written into the PLC, the corresponding

parameters will be copied to relevant special registers. After that, if there is a demand to change positioning

parameters during PLC is in operation, the user just needs to change the values in relevant special registers before to

execute the positioning control instruction. Then, the positioning control instruction will base on the changed values in

the special registers to execute the instruction. For example, to change the time of acceleration or deceleration.

To open the setup page, select the option “Positioning Parameter Setup” under the “Project” of the Ladder Master S.

Hereby we illustrate the setting for each item on the page one by one.

Loading...

Loading...