Operation

0540−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Operation with Running Gear Partially or Fully Removed

1. General

If the engine must operate with a defect in the

running gear, which cannot be immediately

repaired, do the procedures given in

paragraph 3 to paragraph 7.

Note: You can operate the engine only at

decreased load.

For more data, see 0500−1, paragraph 1 to

paragraph 3.

The exhaust gas temperature after cylinder

must be less than the maximum limit of

515_C.

2. Piston Removed

2.1 Problems

D The piston is cracked or has a leak.

D There is damage to the piston and/or

cylinder liner.

D There is damage to the piston rod gland

and/or piston rod.

3. Preparation

1) Cut out the injection to the related

cylinder (see 0510−1 paragraph 1).

2) Cut out the exhaust valve control unit

(VCU) (see 0520−1 paragraph 2).

3) Make sure that the exhaust valve is

closed (see 4002−2, paragraph 3.8).

4) If necessary, close the cooling water

supply and the return pipe of the

related cylinder.

4. Procedure

1) Disconnect the electrical connection

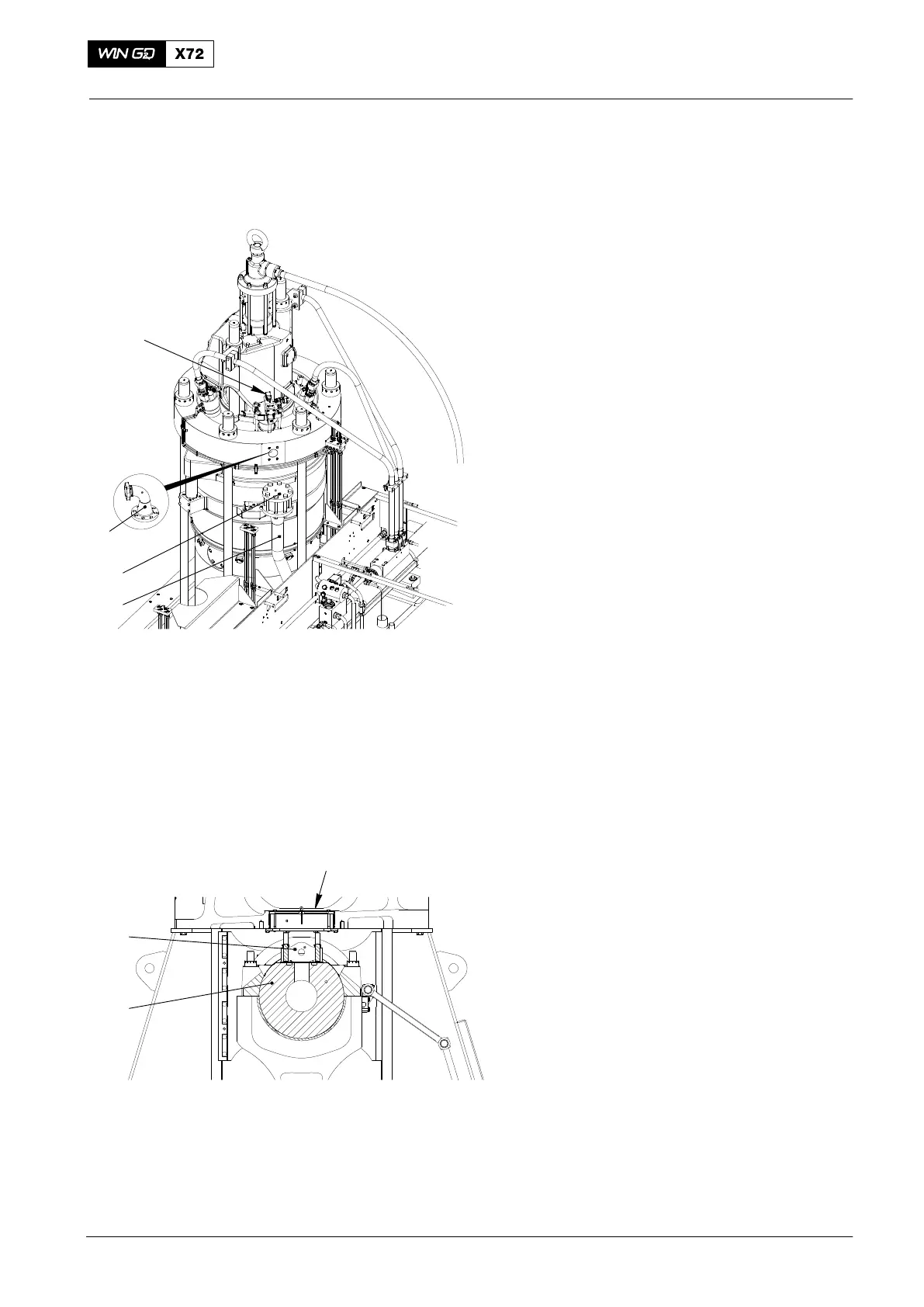

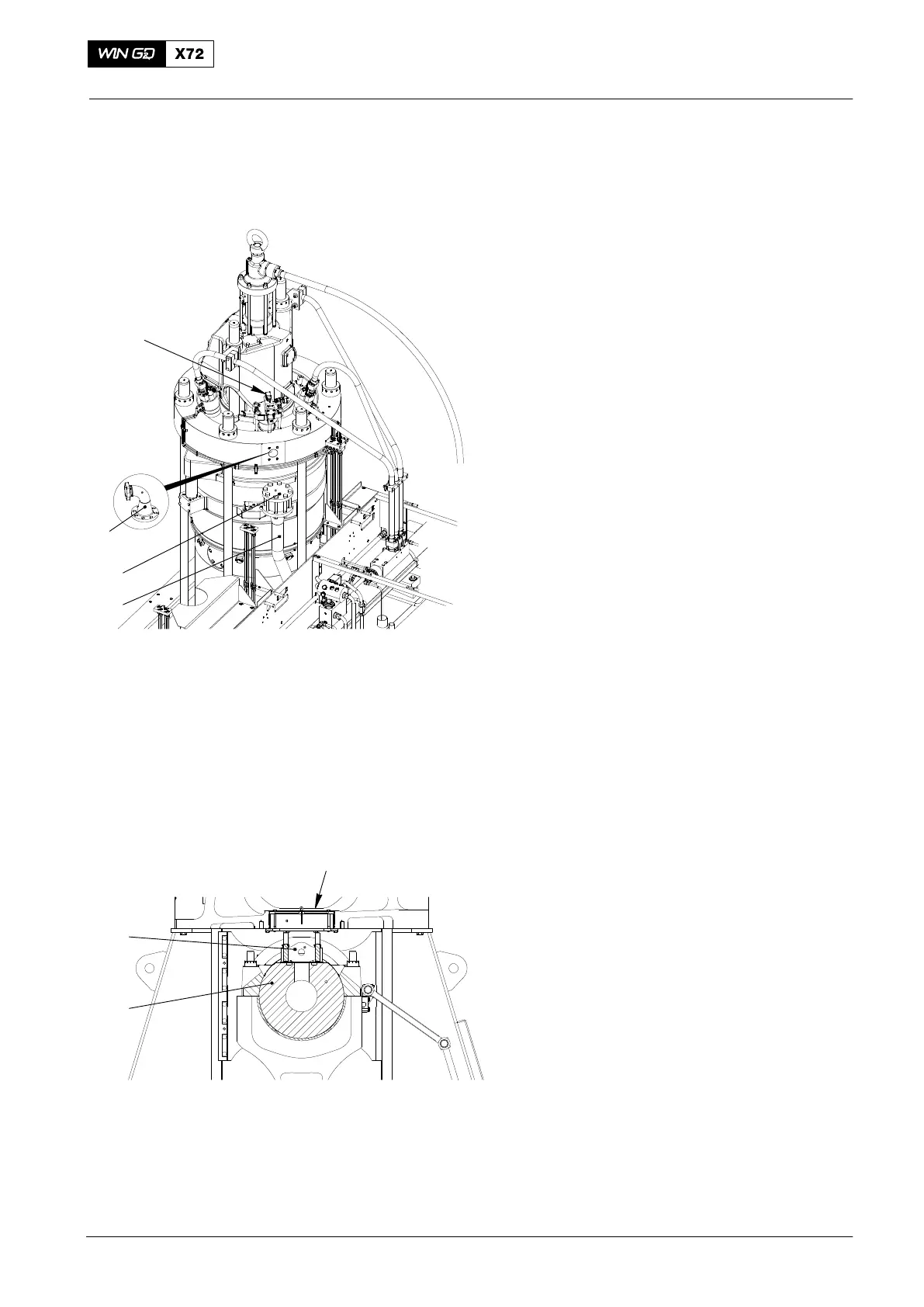

from the starting air valve (1, Fig. 1).

2) Remove the elbow (2) from the starting

air pipe (4).

3) Install the blank flange (3, tool

9486−01) to the starting air pipe (4).

4) Install the cover and the lifting plate (6)

(tool 9433−03) on to the crosshead (7).

5) Install the cover plate (5, tool 9423−01)

in the position of the piston rod gland.

Fig. 1: Tools 9486−01 and 9423−01

Operation during Unusual Conditions

2014

2

1

3

4

5

6

7

WCH02356

WCH02356

Loading...

Loading...