6.12 Absolute Encoders

6.12.9 Multiturn Limit Disagreement Alarm (A.CC0)

6-84

6.12.9

Multiturn Limit Disagreement Alarm (A.CC0)

If you change the multiturn limit in Pn205 (Multiturn Limit), an A.CC0 alarm (Multiturn Limit Dis-

agreement) will be displayed because the setting disagrees with the value in the encoder.

If this alarm is displayed, use the following procedure to change the multiturn limit in the

encoder to the same value as the setting of Pn205.

Applicable Tools

The following table lists the tools that you can use to set the multiturn limit and the applicable

tool functions.

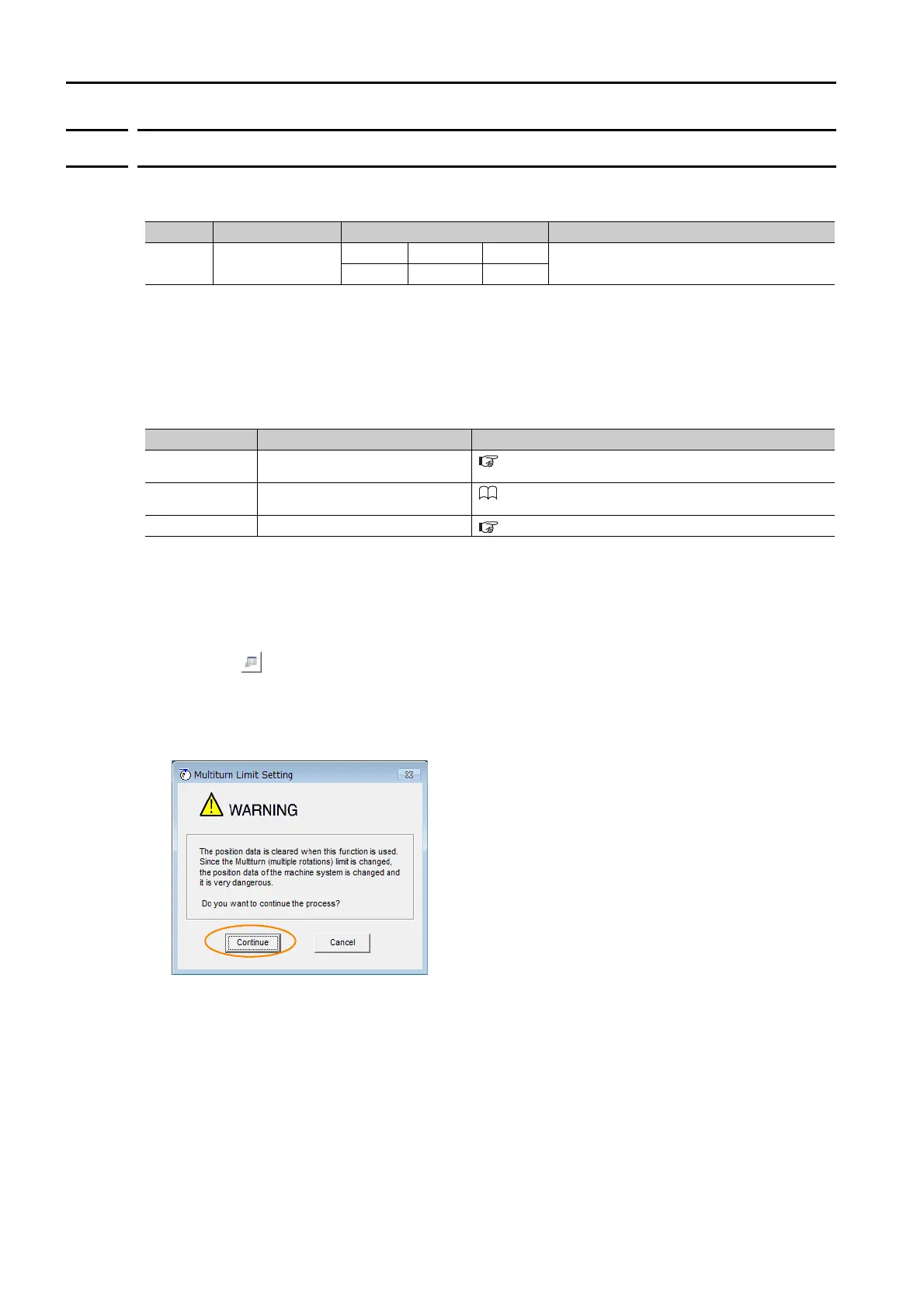

Operating Procedure

Use the following procedure to adjust the multiturn limit setting.

1.

Click the Servo Drive Button in the workspace of the Main Window of the SigmaWin+.

2.

Select Multiturn Limit Setting in the Menu Dialog Box.

The Multiturn Limit Setting Dialog Box will be displayed.

3.

Click the Continue Button.

Click the Cancel Button to cancel setting the multiturn limit.

The Main Window will return.

Display Name Alarm Code Output Meaning

A.CC0

Multiturn Limit Dis-

agreement

ALO1 ALO2 ALO3

Different multiturn limits are set in the

encoder and SERVOPACK.

ON (low) OFF (high) ON (low)

Tool Function Operating Procedure Reference

Panel Operator Fn013

13.4.18 Multiturn Limit Setting after Multiturn Limit Dis-

agreement Alarm (Fn013) on page 13-26

Digital Operator Fn013

Σ-7-Series Digital Operator Operating Manual (Manual

No.: SIEP S800001 33)

SigmaWin+ Setup

−

Multiturn Limit Setting

Operating Procedure on page 6-84

Loading...

Loading...