12.1 Inspections and Part Replacement

12.1.1 Inspections

12-2

12.1

Inspections and Part Replacement

This section describes inspections and part replacement for SERVOPACKs.

12.1.1

Inspections

Perform the inspections given in the following table at least once every year for the SERVO-

PACK. Daily inspections are not required.

12.1.2

Guidelines for Part Replacement

The following electric or electronic parts are subject to mechanical wear or deterioration over

time. Use one of the following methods to check the standard replacement period.

• Use the service life prediction function of the SERVOPACK.

Refer to the following section for information on service life predictions.

9.4 Monitoring Product Life on page 9-15

• Use the following table.

When any standard replacement period is close to expiring, contact your Yaskawa representa-

tive. After an examination of the part in question, we will determine whether the part should be

replaced.

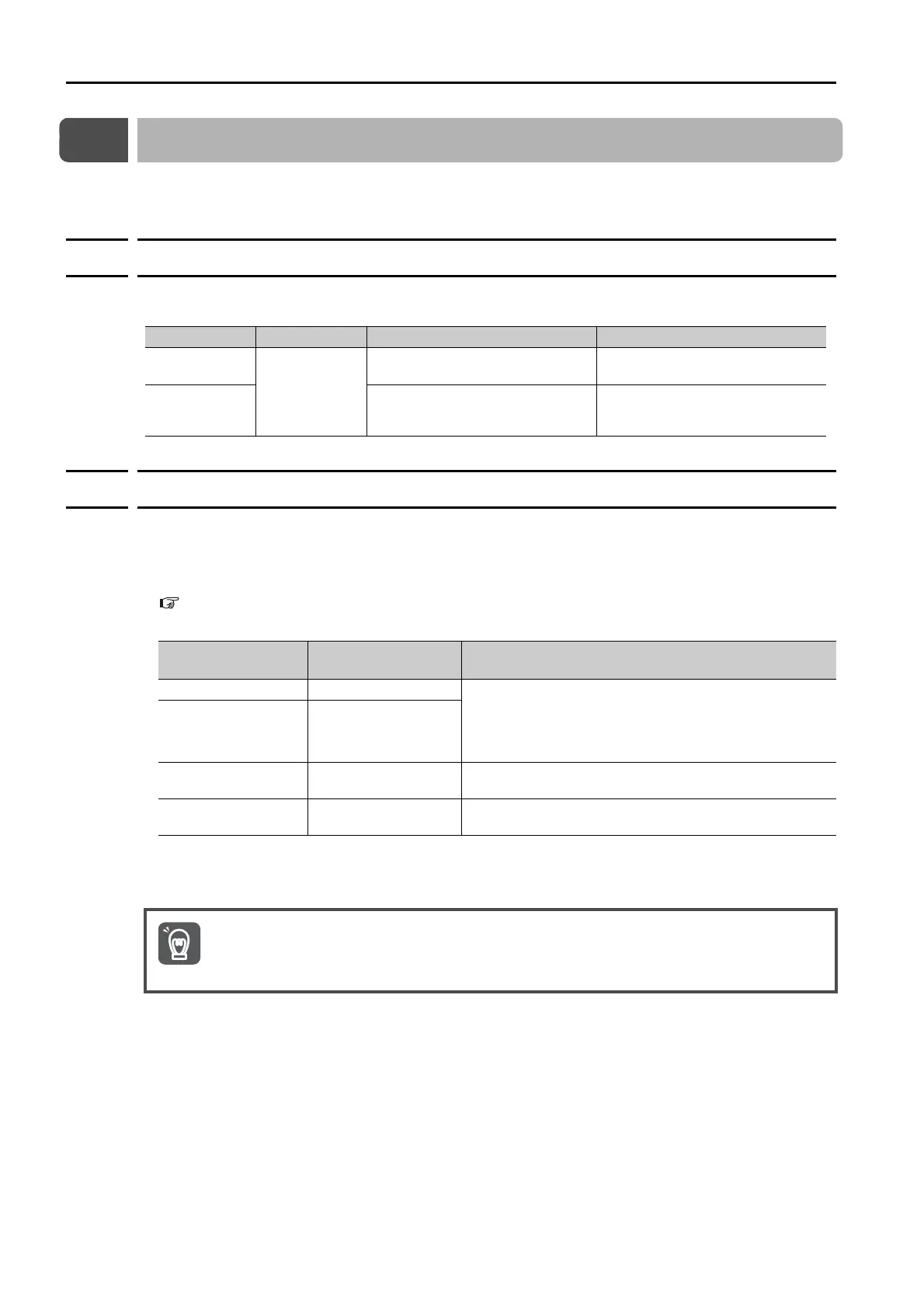

Item Frequency Inspection Correction

Exterior

At least once a

year

Check for dust, dirt, and oil on the

surfaces.

Clean with compressed air or a

cloth.

Loose Screws

Check for loose terminal block and

connector screws and for other

loose parts.

Tighten any loose screws or other

loose parts.

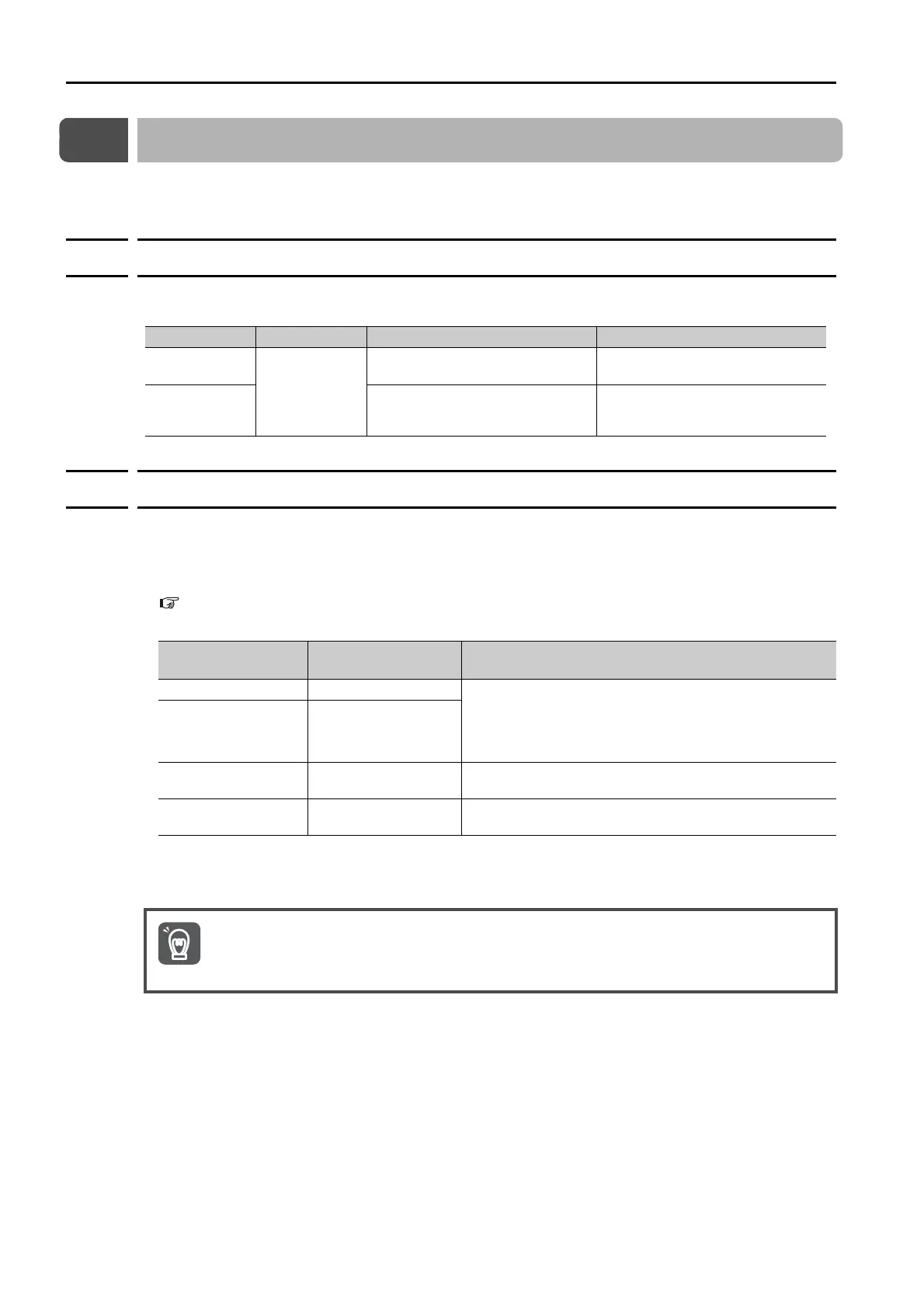

Part

Standard Replace-

ment Period

Remarks

Cooling Fan 4 years to 5 years The standard replacement periods given on the left are for

the following operating conditions.

• Surrounding air temperature: Annual average of 30°C

• Load factor: 80% max.

• Operation rate: 20 hours/day max.

Electrolytic Capacitor 10 years

Relays

100,000 power ON

operations

Power ON frequency: Once an hour

Battery

3 years without power

supplied

Surrounding temperature without power supplied: 20°C

The parameters of any SERVOPACKs that are sent to Yaskawa for part replacement are reset to

the factory settings before they are returned to you. Always keep a record of the parameter set-

tings. And, always confirm that the parameters are properly set before starting operation.

Loading...

Loading...