5.11 Polarity Detection

5.11.1 Restrictions

5-27

5

Basic Functions That Require Setting before Operation

5.11

Polarity Detection

If you use a Linear Servomotor that does not have a polarity sensor, then you must detect the

polarity.

Detecting the polarity means that the position of the electrical phase angle on the electrical

angle coordinates of the Servomotor is detected. The SERVOPACK cannot control the Servo-

motor correctly unless it accurately knows the position of the electrical angle coordinate of the

Servomotor.

The execution timing and execution method for polarity detection depend on the encoder

specification as described in the following table.

5.11.1

Restrictions

Assumed Conditions

The Servomotor will move when you execute polarity detection. The following conditions must

be met before you start.

• It must be OK to move the Moving Coil about 10 mm.

(If polarity detection fails, the Moving Coil may move approximately 5 cm. The amount of

movement depends on conditions.)

• The linear encoder pitch must be 100 μm or less. (We recommend a pitch of 40 μm or less

for an incremental encoder.)

• As much as possible, the motor must not be subjected to an imbalanced external force. (We

recommend 5% or less of the rated force.)

• The mass ratio must be 50x or less.

• The axis must be horizontal.

• There must be friction equivalent to a few percent of the rated force applied to the guides. (Air

sliders cannot be used.)

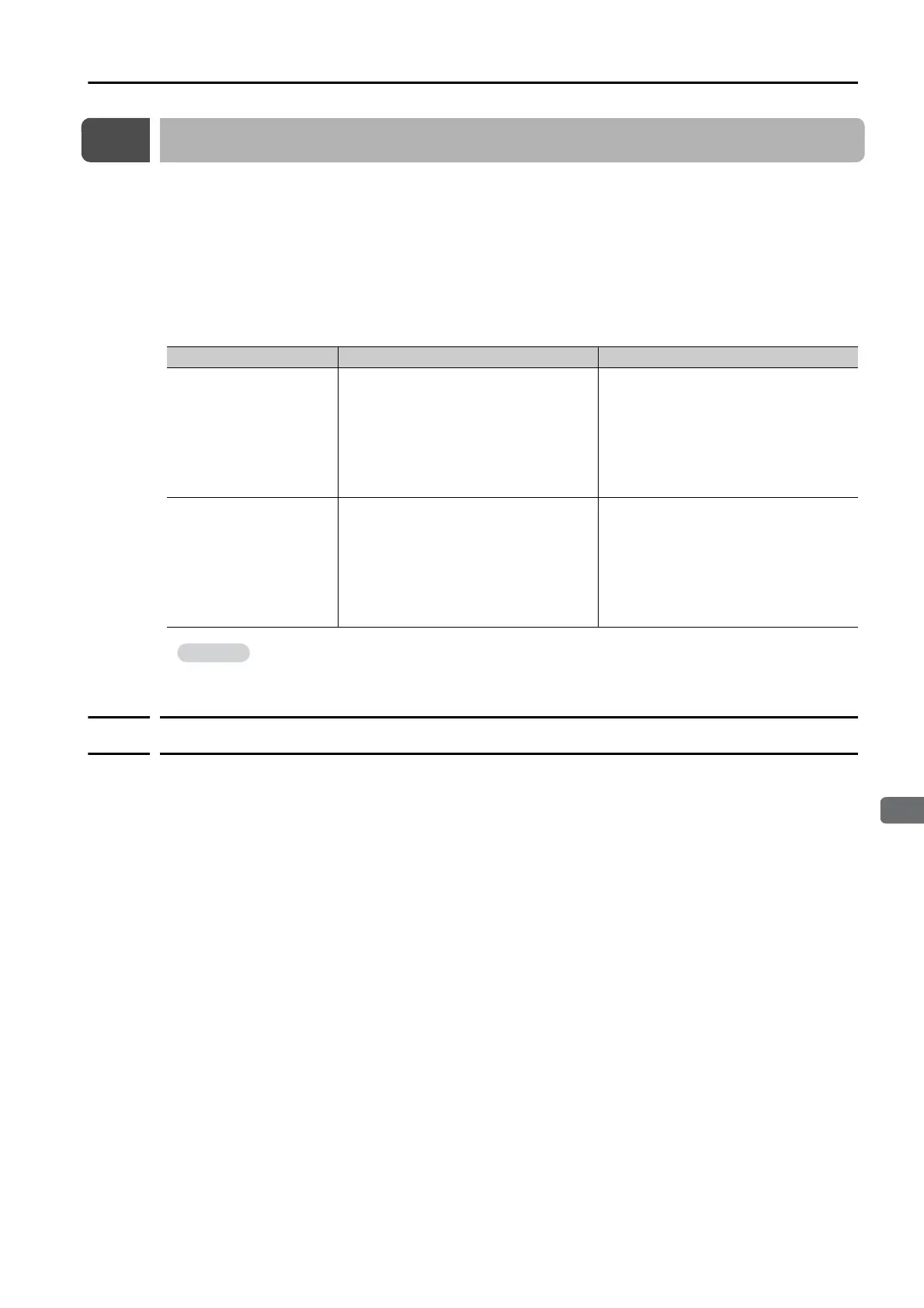

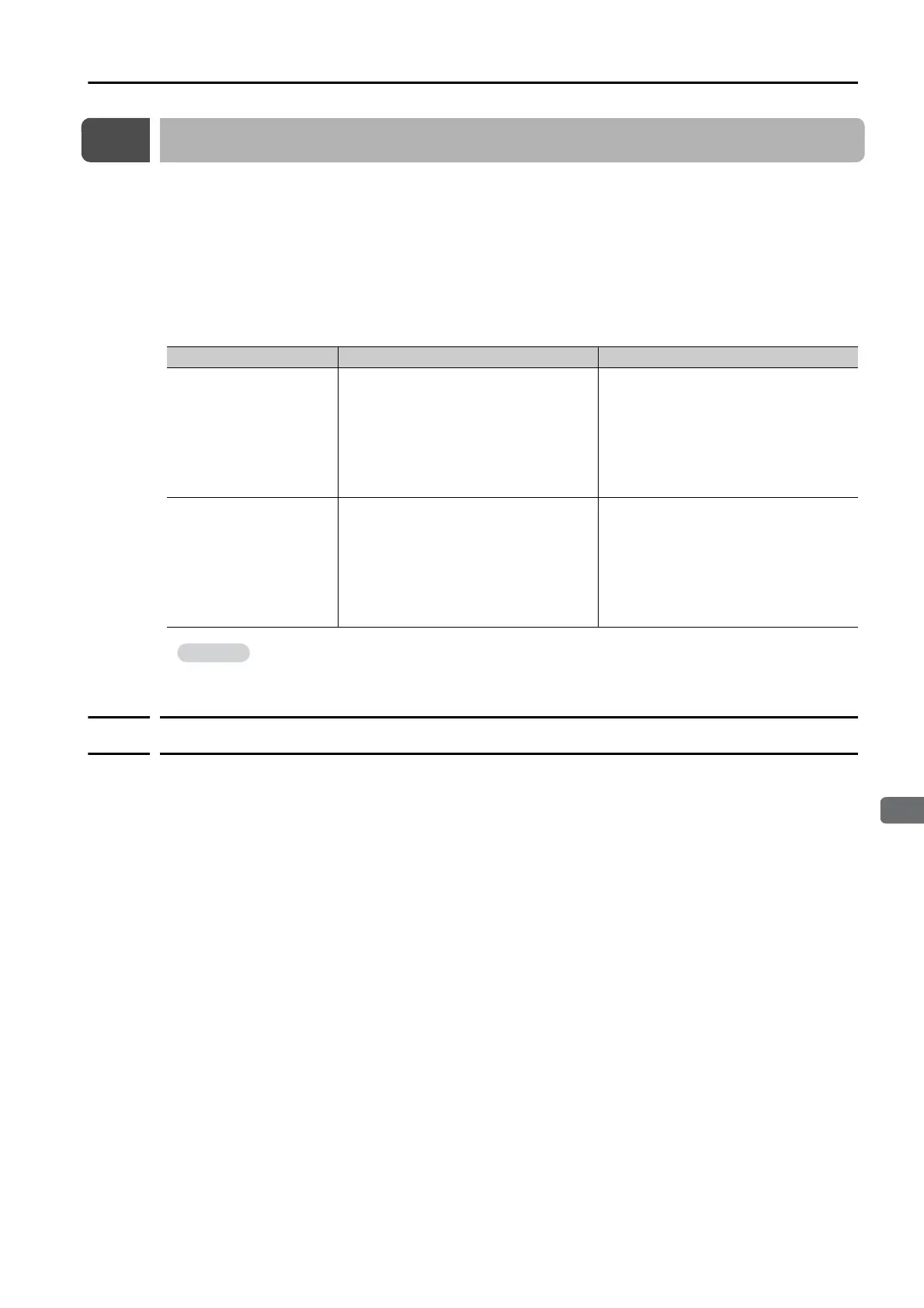

Encoder Specification Polarity Detection Execution Timing Polarity Detection Execution Method

Incremental encoder

Each time the control power supply to

the SERVOPACK is turned ON

(Even after you execute polarity detec-

tion, the position of the polarity will be

lost the next time the control power

supply to the SERVOPACK is turned

OFF.)

• Use the /S-ON (Servo ON) signal.

• Use the /P-DET (Polarity Detection)

signal.

• Use the polarity detection function of

the SigmaWin+.

• Execute the Fn080 (Polarity Detection)

utility function from the Digital Opera-

tor or Panel Operator.

Absolute encoder

Only for initial setup, or after the

SERVOPACK, linear encoder, or motor

has been replaced

(The results of polarity detection is

stored in the absolute encoder, so the

polarity position is not lost when the

control power supply is turned OFF.)

• Use the polarity detection function of

the SigmaWin+.

• Execute the Fn080 (Polarity Detection)

utility function from the Digital Opera-

tor or Panel Operator.

If you use a Linear Servomotor that does not have a polarity sensor, you will not be able to

turn ON the servo until polarity detection has been completed.

Loading...

Loading...