9.5 Alarm Tracing

9.5.1 Data for Which Alarm Tracing Is Performed

9-18

9.5

Alarm Tracing

Alarm tracing records data in the SERVOPACK from before and after an alarm occurs. This

data helps you to isolate the cause of the alarm.

You can display the data recorded in the SERVOPACK as a trace waveform on the SigmaWin+.

9.5.1

Data for Which Alarm Tracing Is Performed

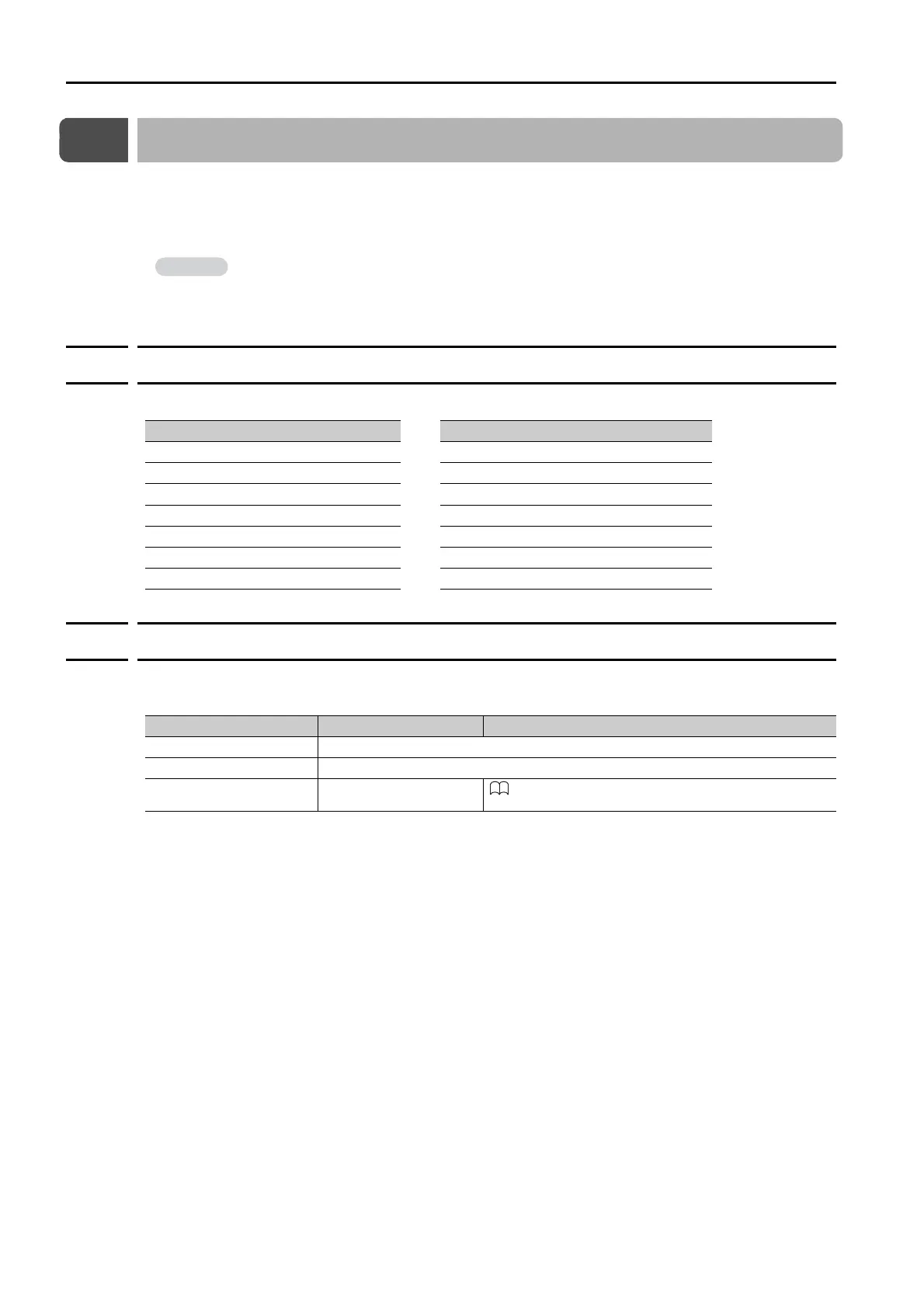

Two types of data are recorded for alarm tracing: numeric data and I/O signal ON/OFF data.

9.5.2

Applicable Tools

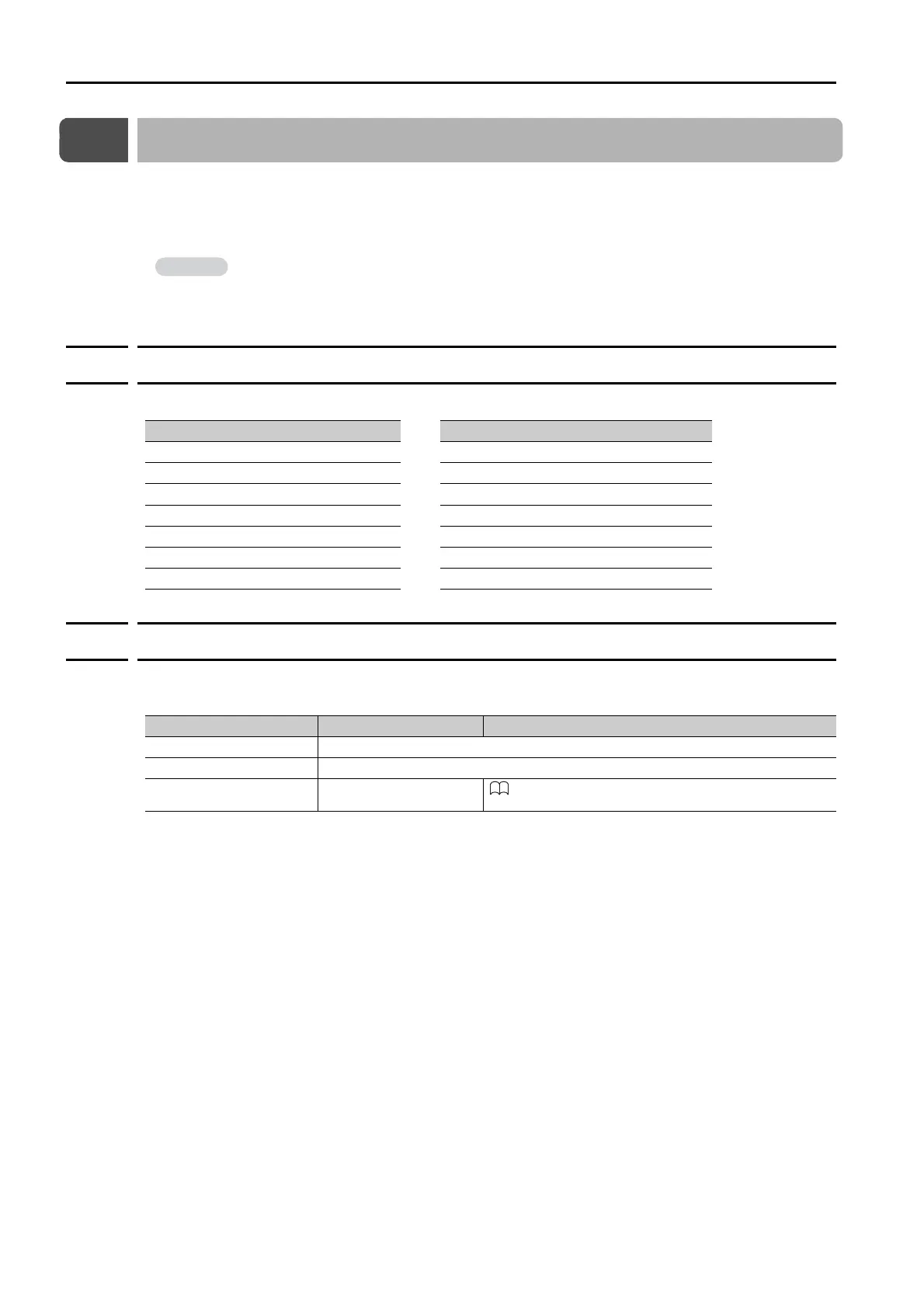

The following table lists the tools that you can use to perform alarm tracing and the applicable

tool functions.

• Alarms that occur when the power supply is turned ON are not recorded.

• Alarms that occur during the recording of alarm trace data are not recorded.

• Alarms that occur while utility functions are being executed are not recorded.

Numeric Data ON/OFF Data

Torque reference ALM

Feedback speed Servo ON command (/S-ON)

Reference speed Proportional control command (/P-CON)

Position reference speed Forward torque command (/P-CL)

Position deviation Reverse torque command (/N-CL)

Motor-load position deviation G-SEL1 signal (/G-SEL1)

Main circuit bus voltage ACON

Tool Function Operating Procedure Reference

Panel Operator You cannot display alarm tracing data from the Panel Operator.

Digital Operator You cannot display alarm tracing data from the Digital Operator.

SigmaWin+ Alarm - Alarm Tracing

AC Servo Drive Engineering Tool SigmaWin+

Operation Manual (Manual No.: SIET S800001 34)

Loading...

Loading...