7.4 Trial Operation with DeviceNet Communications

7-10

7.4

Trial Operation with DeviceNet Communications

A trial operation example for DeviceNet communications is given below.

Refer to the following chapter for details on commands.

Chapter 12 DeviceNet Functions

1.

Connect the DeviceNet communications connector (CN6 connector).

2.

Confirm that the wiring is correct, and then connect the I/O signal connector (CN1 con-

nector).

Refer to the following chapter for details on wiring.

Chapter 4 Wiring and Connections

3.

Turn ON the power supplies to the SERVOPACK.

If power is being supplied correctly, the CHARGE indicator on the SERVOPACK will light.

4.

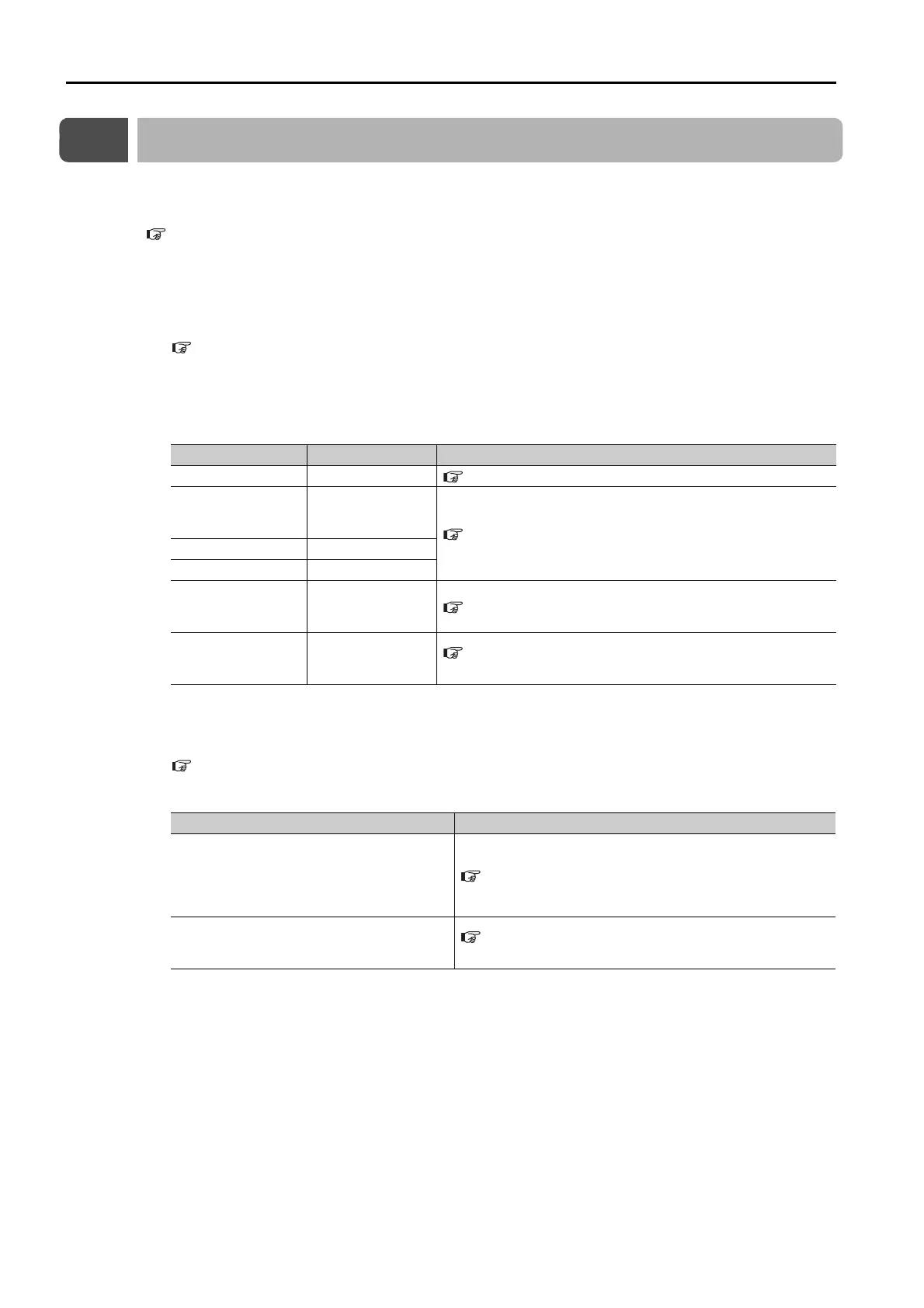

Set the following items, which are necessary for trial operation.

* Set Pn507 for a Rotary Servomotor and Pn583 for a Linear Servomotor.

5.

Use DeviceNet I/O communications to perform positioning.

Refer to the following section for details on operation.

12.3 Positioning on page 12-6

6.

While operation is in progress for step 5, confirm the following items.

Note: If the load machine is not sufficiently broken in before trial operation, the Servomotor may become over-

loaded.

Setting Parameters to Set Reference

Motor Direction Pn000

5.4 Motor Direction Setting on page 5-16

Feed Speed

PnB21

PnB26

PnB29

12.3 Positioning on page 12-6

Acceleration Rate PnB2A

Deceleration Rate PnB2B

Holding Brake

Pn506

Pn507 (Pn583)*

Pn508

5.11 Holding Brake on page 5-30

Motor Stopping

Method after Servo

OFF and Alarms

Pn001

Pn00B

5.12 Motor Stopping Method for Servo OFF and Alarms on

page 5-34

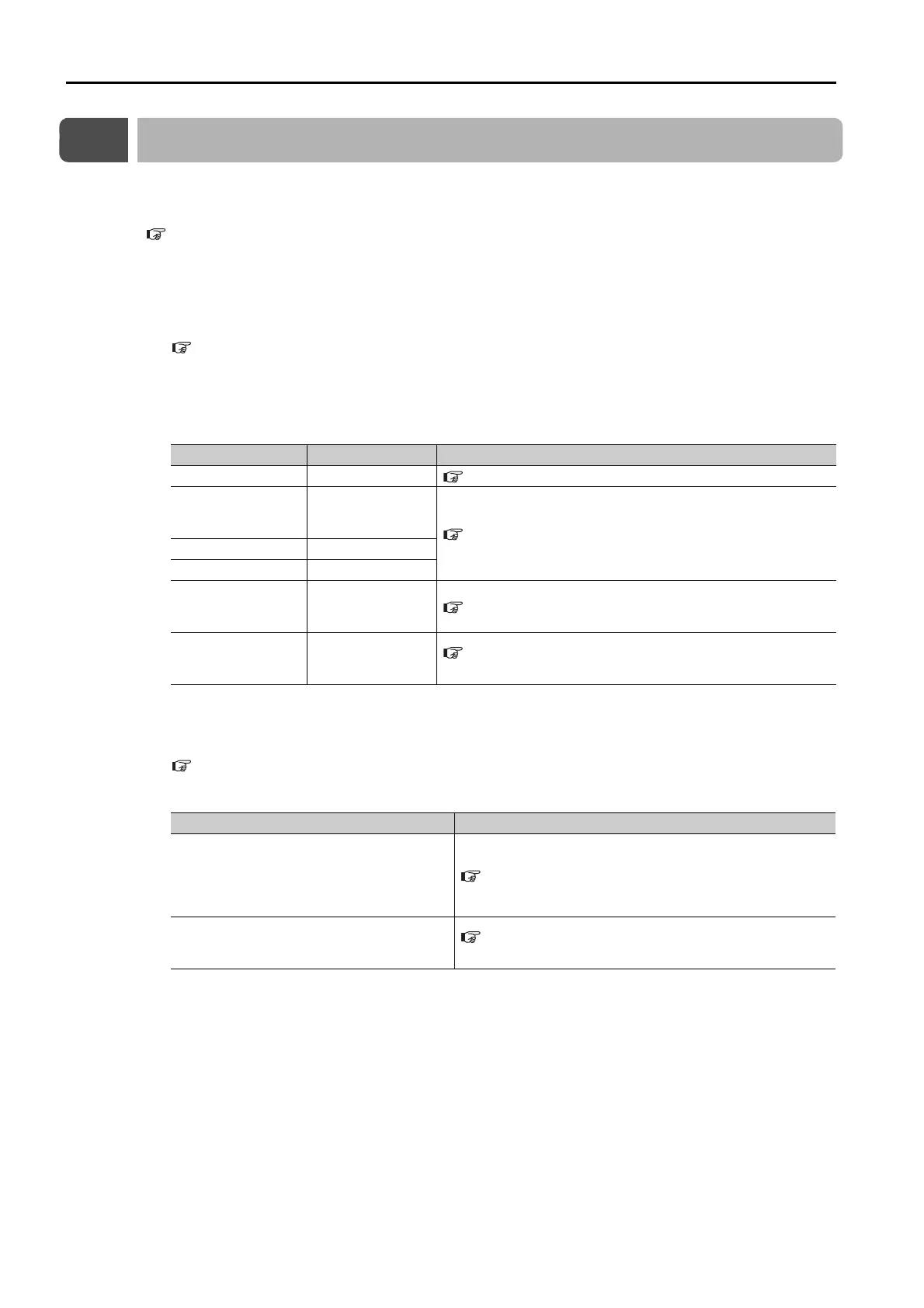

Confirmation Item Reference

Confirm that the rotational direction of the

Servomotor agrees with the forward or

reverse reference. If they do not agree, cor-

rect the rotation direction of the Servomo-

tor.

5.4 Motor Direction Setting on page 5-16

Confirm that no abnormal vibration, noise,

or temperature rise occurs. If any abnor-

malities are found, implement corrections.

14.4 Troubleshooting Based on the Operation and Condi-

tions of the Servomotor on page 14-56

Loading...

Loading...