10.3 Parameter Settings for Fully-Closed Loop Control

10.3.5 Electronic Gear Setting

10-8

Related Parameters

Note: The maximum setting for the encoder output resolution is 4,096.

If the resolution of the external encoder exceeds 4,096, pulse output will no longer be possible at the resolu-

tion given in

Feedback Resolution of Linear Encoder on page 5-43.

10.3.5

Electronic Gear Setting

Refer to the following section for details.

5.14 Electronic Gear Settings on page 5-40

With fully-closed loop control, the same setting as for a Linear Servomotor is used.

10.3.6

Alarm Detection Settings

This section describes the alarm detection settings (Pn51B and Pn52A).

Pn51B (Motor-Load Position Deviation Overflow Detection

Level)

This setting is used to detect the difference between the feedback position of the Servomotor

encoder and the feedback load position of the external encoder for fully-closed loop control.

If the detected difference exceeds the setting, an A.d10 alarm (Motor-Load Position Error Over-

flow) will be output.

Note: If you set this parameter to 0, A.d10 alarms will not be output and the machine may be damaged.

Pn52A (Multiplier per Fully-closed Rotation)

Set the coefficient of the deviation between the Servomotor and the external encoder per Ser-

vomotor rotation.

This setting can be used to prevent the Servomotor from running out of control due to damage

to the external encoder or to detect belt slippage.

If the setting is 20 and the speed is 1,600 mm/s, the output frequency would be 1.6 Mpps

= 1,600,000 = 1.6 Mpps

Because 1.6 Mpps is less than 6.4 Mpps, this setting can be used.

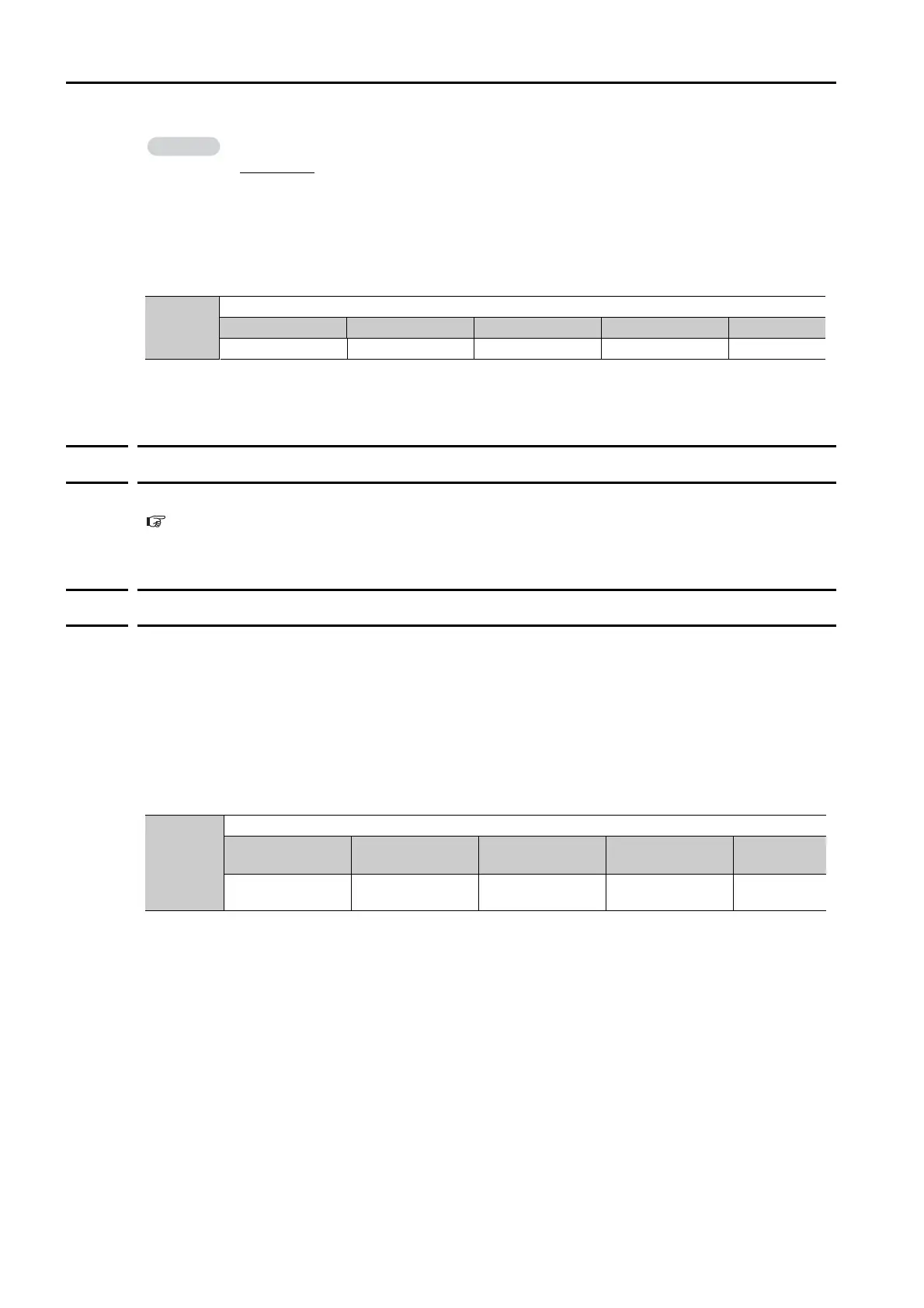

Pn281

Encoder Output Resolution

Setting Range Setting Unit Default Setting When Enabled Classification

1 to 4,096 1 edge/pitch 20 After restart Setup

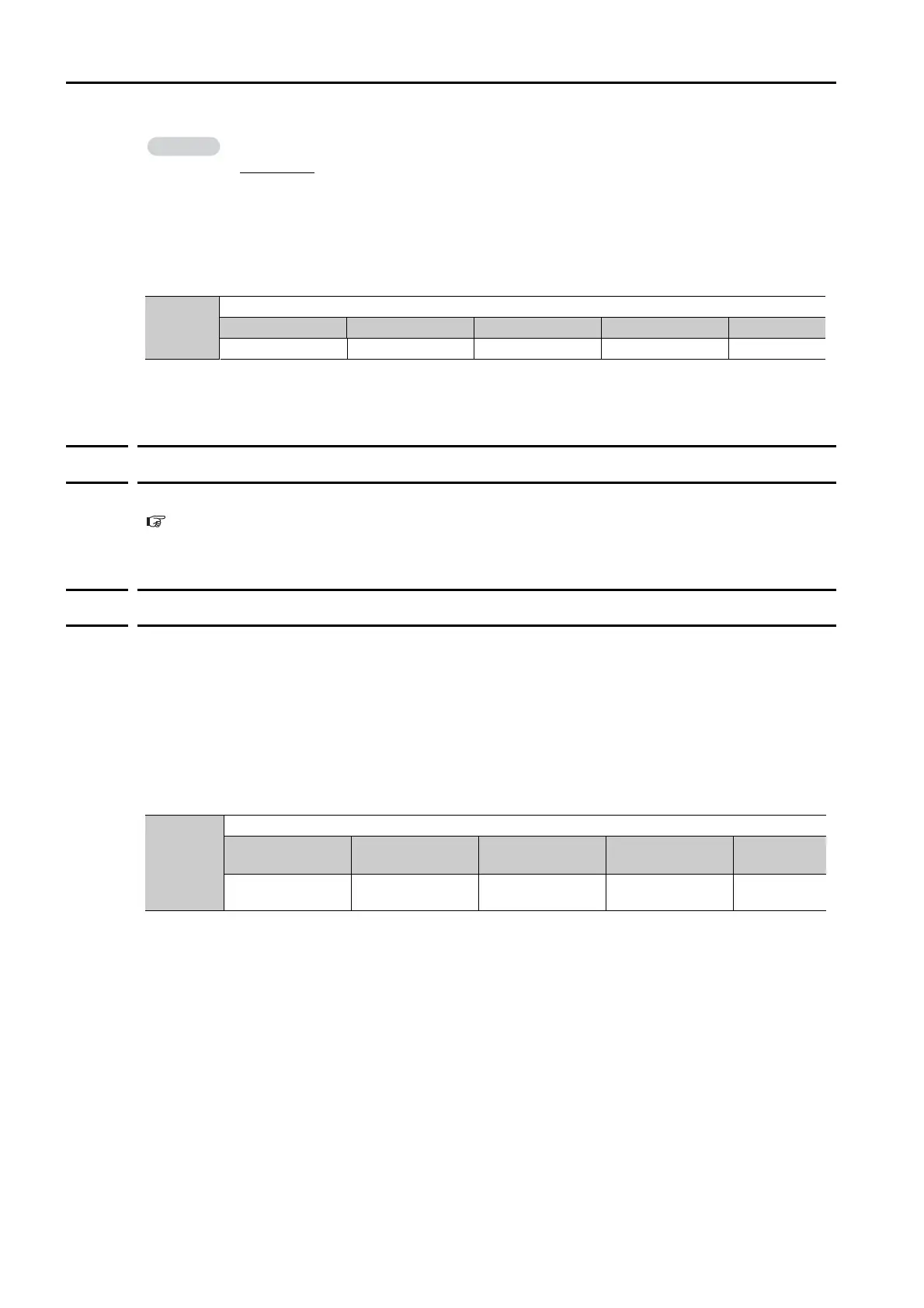

Pn51B

Motor-Load Position Deviation Overflow Detection Level

Setting Range Setting Unit Default Setting When Enabled

Classifica-

tion

0 to

1,073,741,824

1 reference unit 1000 Immediately Setup

Loading...

Loading...