10.3 Parameter Settings for Fully-Closed Loop Control

10.3.7 Analog Monitor Signal Settings

10

Fully-Closed Loop Control

10-9

Setting Example

Increase the value if the belt slips or is twisted excessively.

If this parameter is set to 0, the external encoder value will be read as it is.

If you use the default setting of 20, the second rotation will start with the deviation for the first

Servomotor rotation multiplied by 0.8.

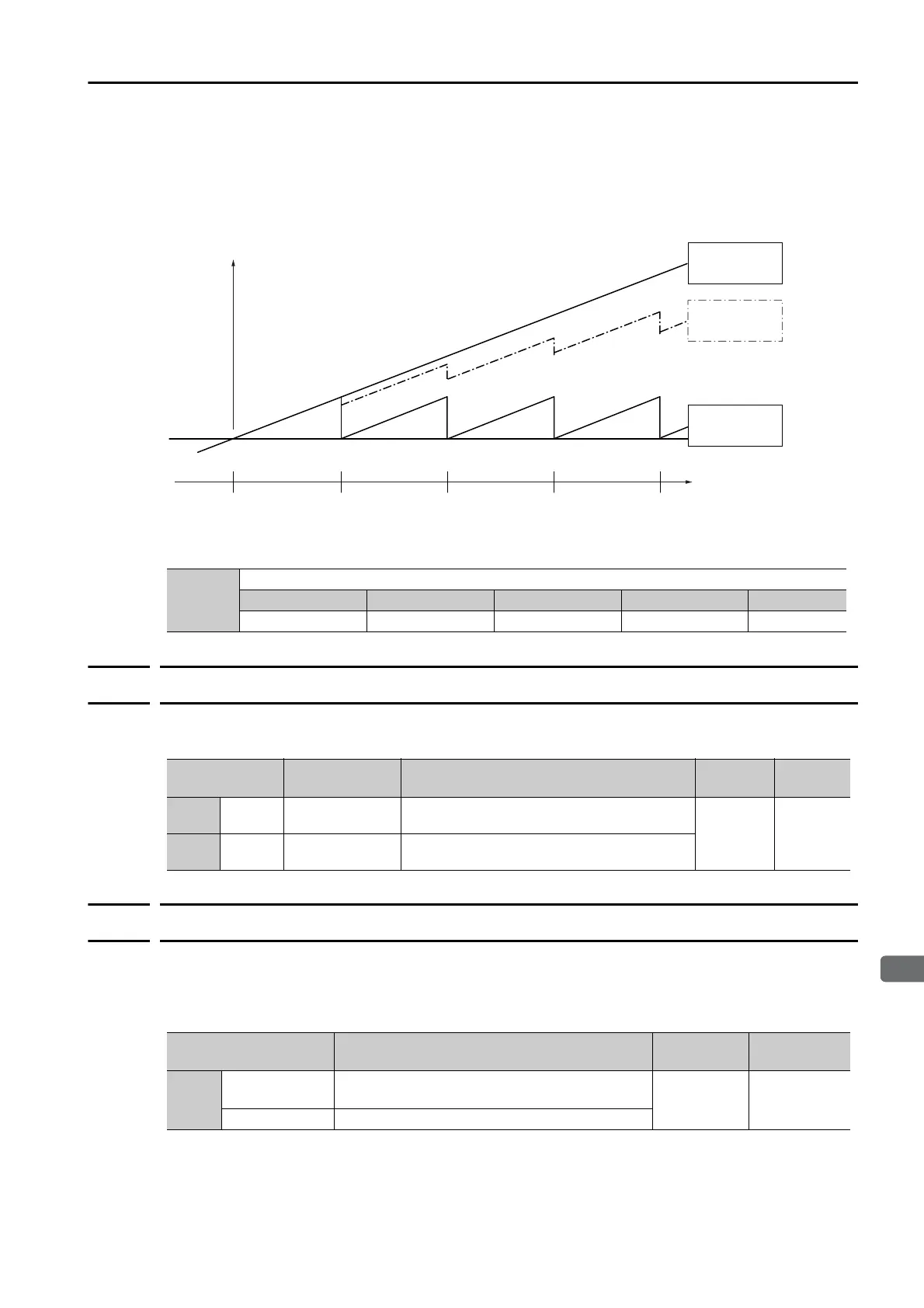

Related Parameters

10.3.7

Analog Monitor Signal Settings

You can monitor the position deviation between the Servomotor and load with an analog moni-

tor.

10.3.8

Setting to Use an External Encoder for Speed Feedback

For fully-closed loop control, you normally set a parameter to specify using the motor encoder

speed (Pn22A = n.0).

If you will use a Direct Drive Servomotor and a high-resolution external encoder, set the param-

eter to specify using the speed of the external encoder (Pn22A = n.1).

Note: This parameter cannot be used if Pn002 is set to n.0 (Do not use external encoder).

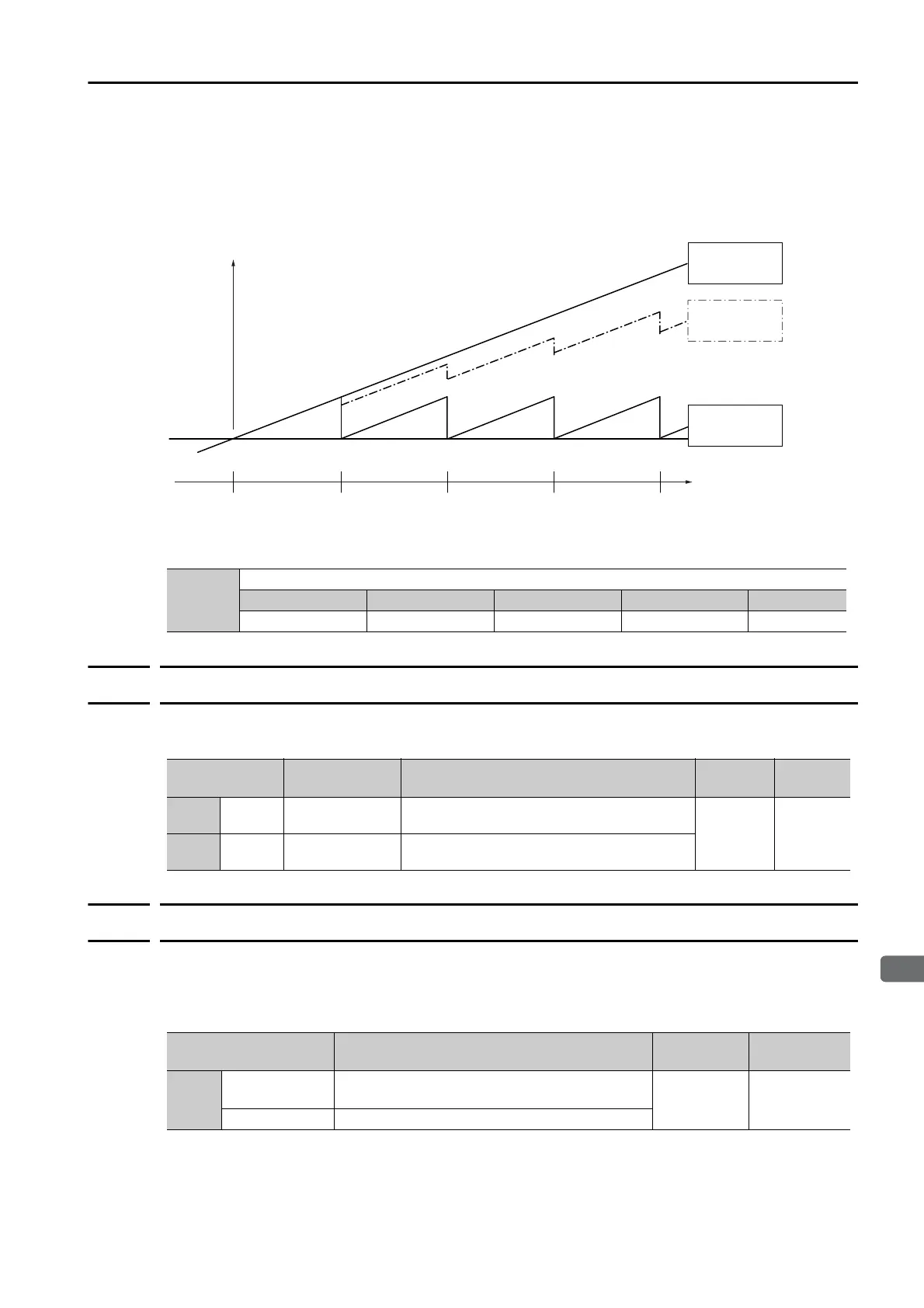

Pn52A

Multiplier per Fully-closed Rotation

Setting Range Setting Unit Default Setting When Enabled Classification

0 to 100 1% 20 Immediately Setup

Pn52A = 0

Pn52A = 100

Pn52A = 20

Deviation between Servomotor and external encoder

Large

Number of Servomotor rotations

4th rotation3rd rotation

1st rotation

2nd rotation

Small

Parameter Name Meaning

When

Enabled

Classifi-

cation

Pn006 n.07

Analog Monitor 1

Signal Selection

Position deviation between motor and load

(output unit: 0.01 V/reference unit).

Immedi-

ately

Setup

Pn007 n.07

Analog Monitor 2

Signal Selection

Position deviation between motor and load

(output unit: 0.01 V/reference unit).

Parameter Meaning

When

Enabled

Classification

Pn22A

n.0

(default setting)

Use motor encoder speed.

After restart Setup

n.1 Use external encoder speed.

Loading...

Loading...