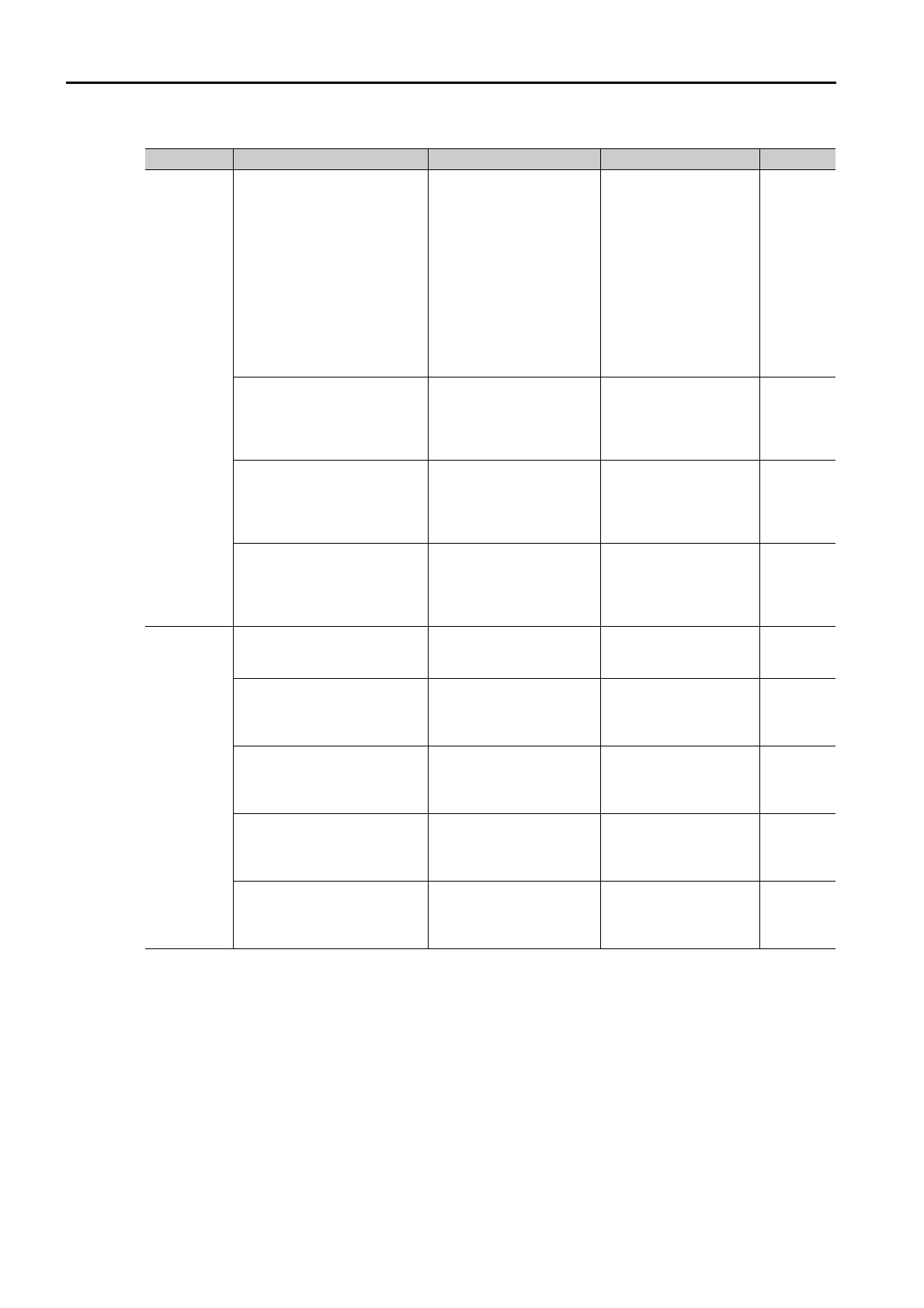

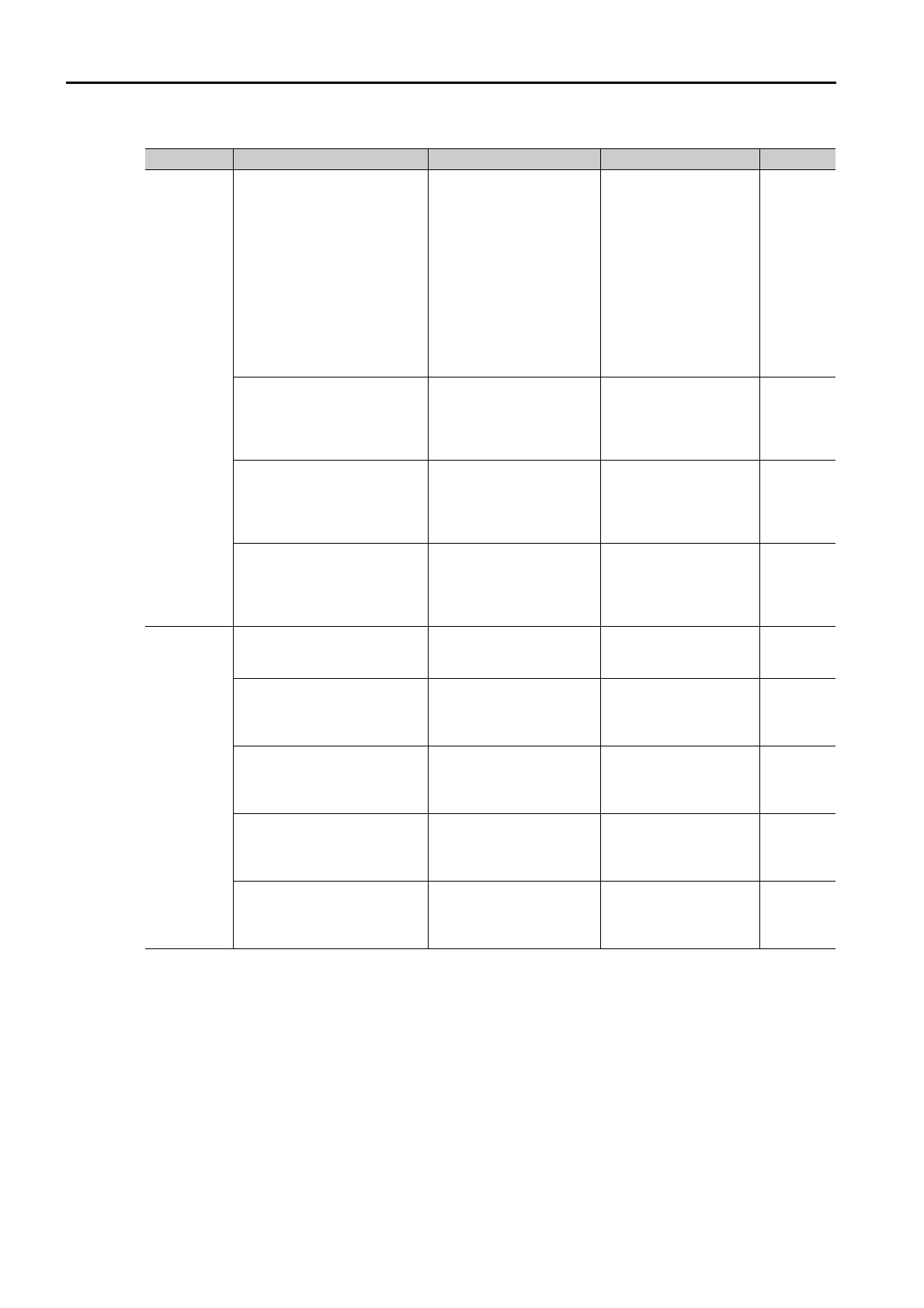

14.4 Troubleshooting Based on the Operation and Conditions of the Servomotor

14-60

Abnormal

Noise from

Servomotor

The encoder was subjected

to excessive vibration or

shock.

Turn OFF the power sup-

ply to the servo system.

Check to see if vibration

from the machine

occurred. Check the Ser-

vomotor installation

(mounting surface preci-

sion, securing state, and

alignment).

Check the linear encoder

installation (mounting sur-

face precision and secur-

ing method).

Reduce machine vibra-

tion. Improve the

mounting state of the

Servomotor or linear

encoder.

−

A failure occurred in the

encoder.

−

Turn OFF the power

supply to the servo

system.

Replace the Servomo-

tor.

−

A failure occurred in the

Serial Converter Unit.

−

Turn OFF the power

supply to the servo

system.

Replace the Serial Con-

verter Unit.

−

A failure occurred in the linear

encoder.

−

Turn OFF the power

supply to the servo

system.

Replace the linear

encoder.

−

Servomotor

Vibrates at

Frequency

of Approx.

200 to 400

Hz.

The servo gains are not bal-

anced.

Check to see if the servo

gains have been cor-

rectly tuned.

Perform autotuning

without a host refer-

ence.

page 8-23

The setting of Pn100 (Speed

Loop Gain) is too high.

Check the setting of

Pn100.

The default setting is Kv =

40.0 Hz.

Set Pn100 to an appro-

priate value.

−

The setting of Pn102 (Posi-

tion Loop Gain) is too high.

Check the setting of

Pn102.

The default setting is Kp

= 40.0/s.

Set Pn102 to an appro-

priate value.

−

The setting of Pn101 (Speed

Loop Integral Time Con-

stant) is not appropriate.

Check the setting of

Pn101.

The default setting is Ti =

20.0 ms.

Set Pn101 to an appro-

priate value.

−

The setting of Pn103

(Moment of Inertia Ratio or

Mass Ratio) is not appropri-

ate.

Check the setting of

Pn103.

Set Pn103 to an appro-

priate value.

−

Continued on next page.

Continued from previous page.

Problem Possible Cause Confirmation Correction Reference

Loading...

Loading...