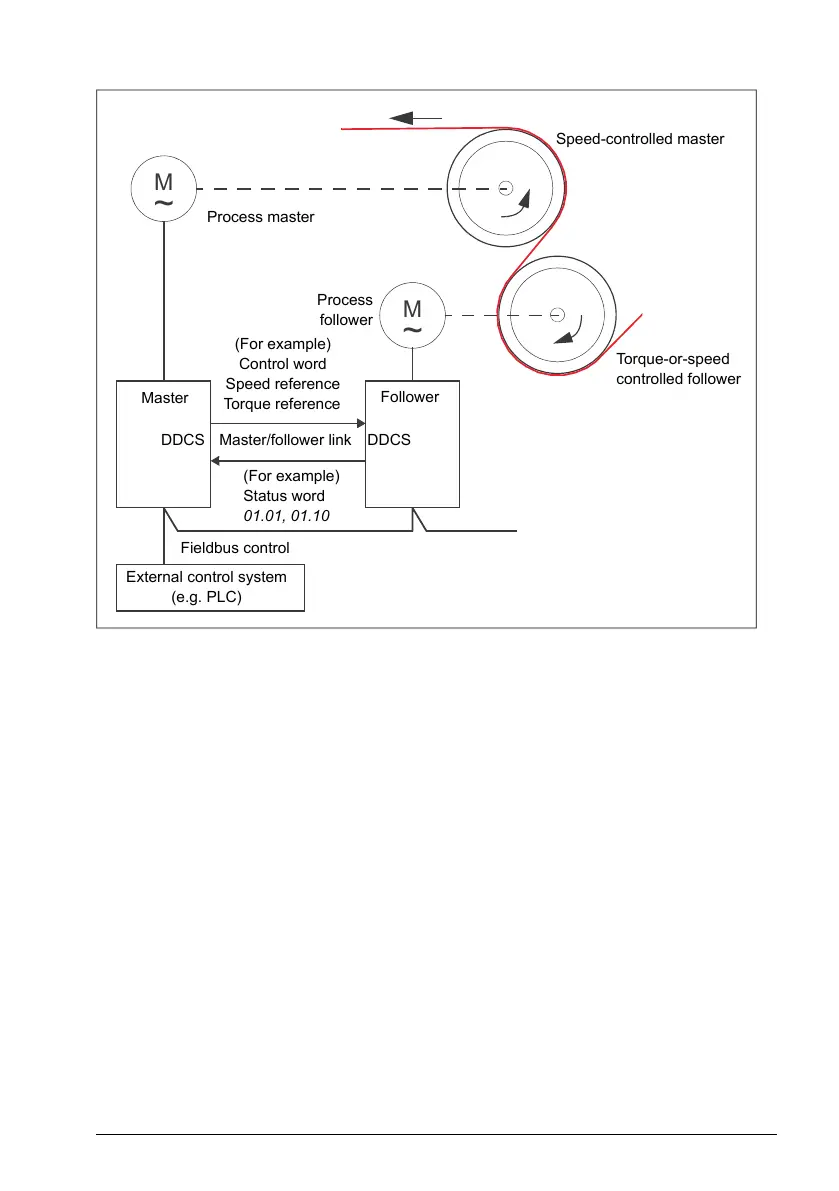

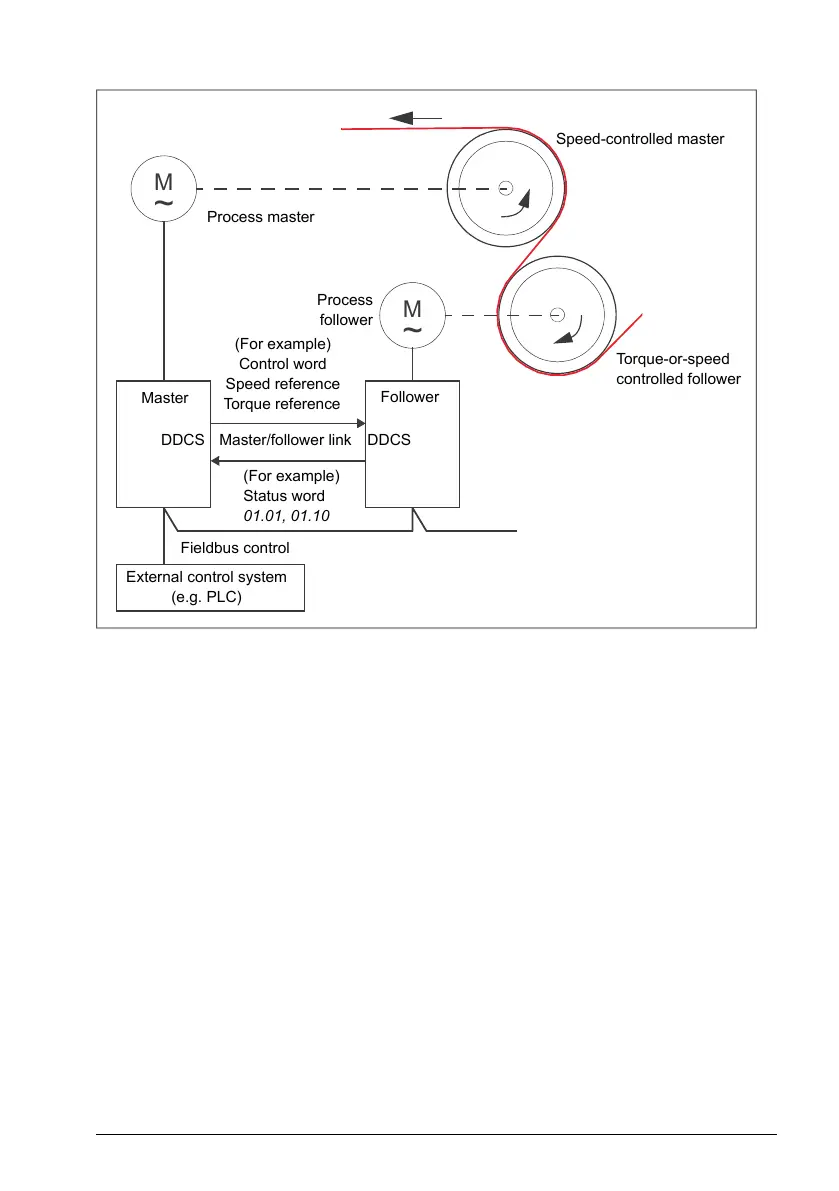

Speed-controlled master

Torque-or-speed

controlled follower

Process master

Process

follower

Master

DDCS

(For example)

Control word

Speed reference

Torque reference

Master/follower link

(For example)

Status word

01.01, 01.10

Fieldbus control

External control system

(e.g. PLC)

DDCS

Follower

The master drive is typically speed-controlled and the other drives follow its torque or

speed reference. In general, a follower should be

• torque-controlled when the motor shafts of the master and the follower are rigidly

coupled by gearing, chain etc. so that no speed difference between the drives is

possible.

• speed-controlled when the motor shafts of the master and the follower are flexibly

coupled so that a slight speed difference is possible. When both the master and the

follower are speed-controlled, drooping is also typically used (see parameter 25.8).

The distribution of load between the master and follower can alternatively be adjusted

as described under Load share function with a speed-controlled follower below.

Note: With a speed-controlled follower (without load sharing), pay attention to the

acceleration and deceleration ramp times of the follower. If the ramp times are set longer

than in the master, the follower will follow its own acceleration/deceleration ramp times

rather than those from the master. In general, it is recommended to set identical ramp

times in both the master and the follower(s). Any ramp shape settings (see parameters

23.16…23.19) should only be applied in the master.

In some applications, both speed control and torque control of the follower are required.

In those cases, the operating mode can be switched by parameter (19.12 or 19.14).

Program features 35

Loading...

Loading...