8210-00020 R1 155

4.2. Fittings Torque Values

These specifications are for carbon steel. With Zinc plating always lubricate threads and seals. For stainless

steel, use the high value of the torque range of steel. For brass, use 70% of the torque value of steel. For mixed

metals, use the torque of the lower of the two metals. Torque range is normally calculated +/- 10%.

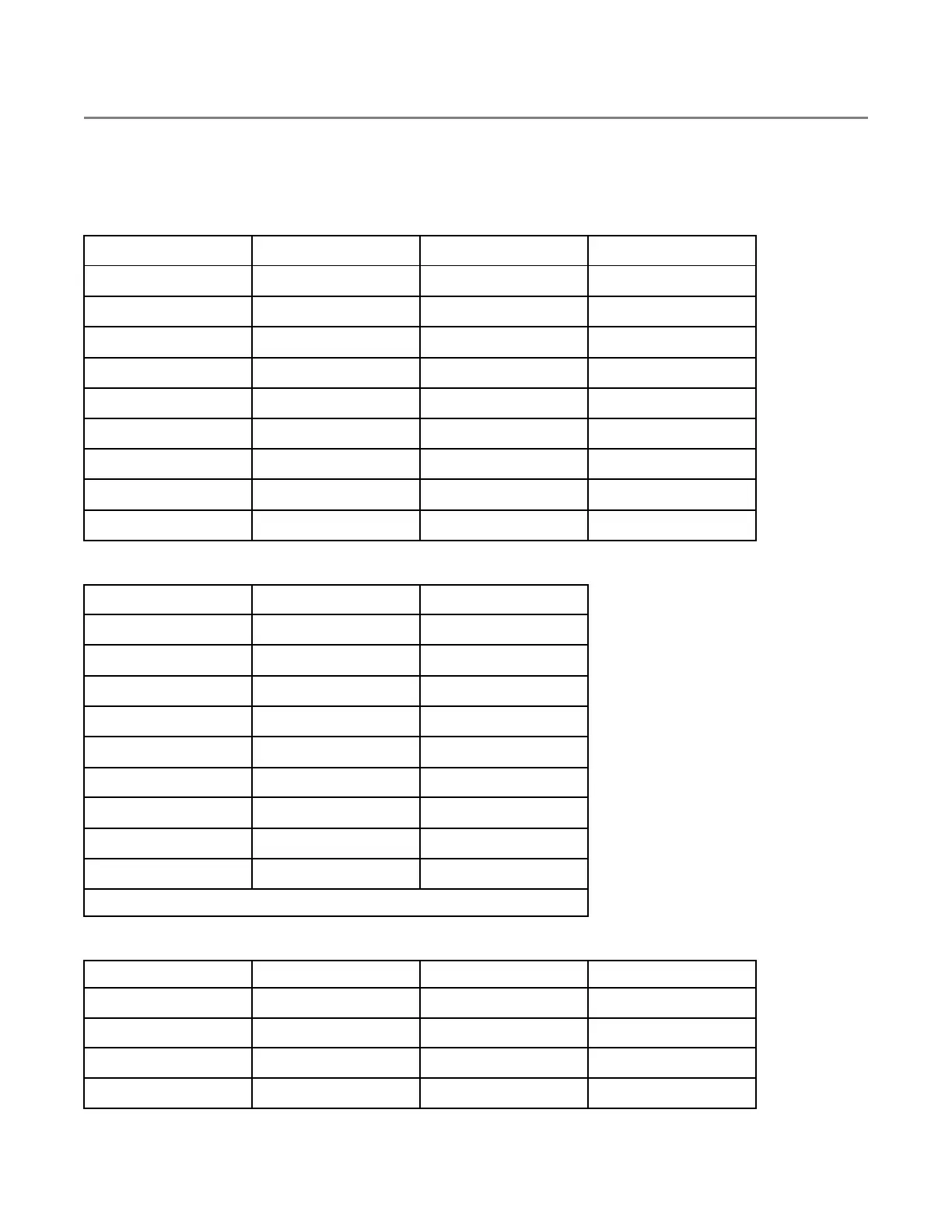

Table 32. Pipe Rigid - Tapered Pipe Threads (NPTF, N/NF) - Carbon Steel

Pipe Size

Turns-from-finger Max ft-lbs

Max N-m

1/8" (-2) 3/4 - 1 3/4

12 16

1/4" (-4) 3/4 - 1 3/4

25 34

3/8" (-6) 3/4 - 1 3/4

40 54

1/2" (-8) 1/2 - 1 1/2

54 73

3/4" (-12) 1/2 - 1 1/2

78 106

1" (-16)

1/2 - 1 1/2

112 152

1 1/4" (-20) 1/2 - 1 1/2

154 209

1 1/2" (-24) 1/2 - 1 1/2

211 286

2" (-32)

1/2 - 1 1/2

300 407

Table 33. Pipe Swivel - Straight Pipe Threads (NPSM, N/NFS) - Carbon Steel

Pipe Size

Max ft-lbs

Max N-m

1/8" (-2)

12 16

1/4" (-4)

25 3

3/8" (-6)

40 54

1/2" (-8)

54 73

3/4" (-12)

78 106

1" (-16)

112 152

1 1/4" (-20)

154 209

1 1/2" (-24)

211 286

2" (-32)

300 407

Note: seals on an internal male 30° seat

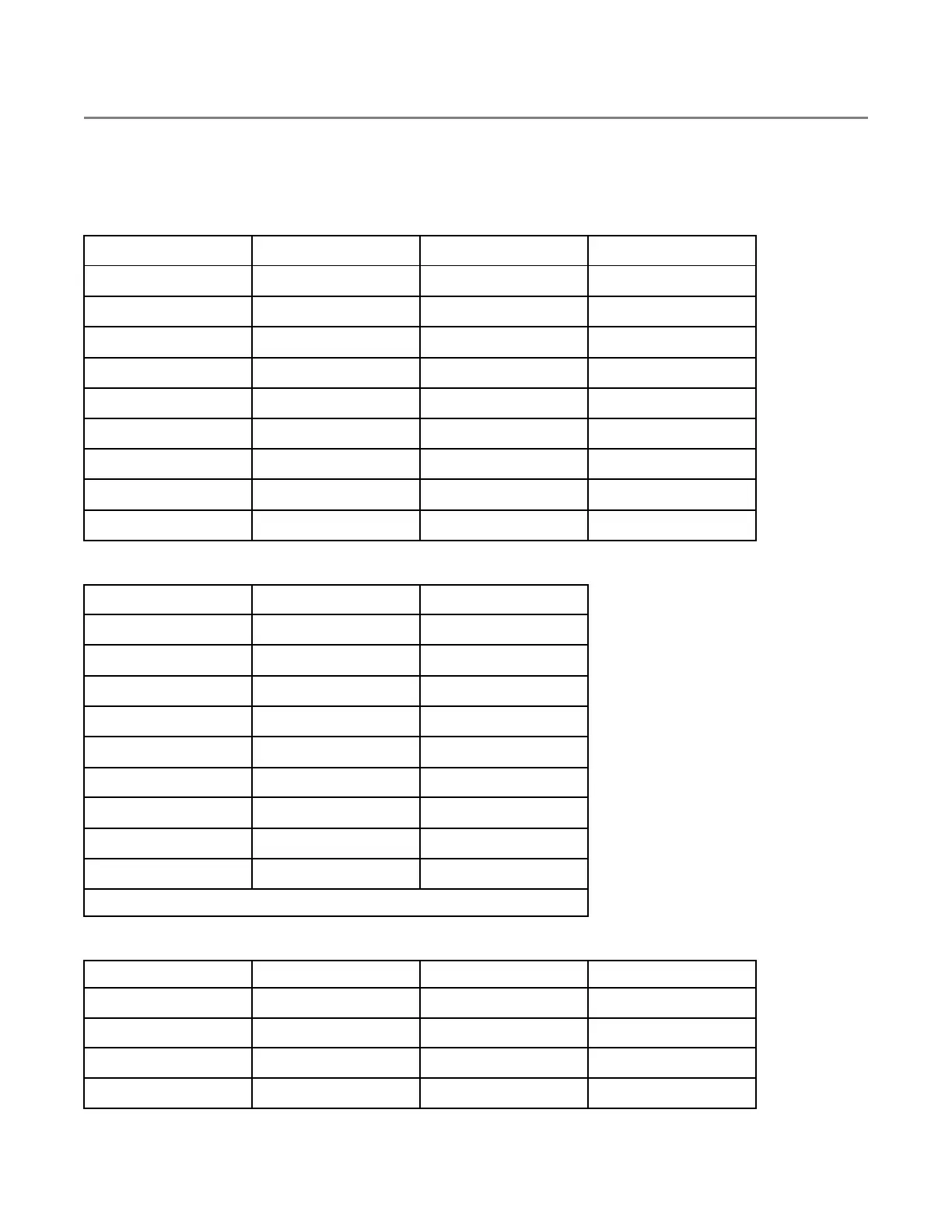

Table 34. Stud End O-Ring Boss (ORB) SAE (U/UF) – Carbon Steel

Tube Size Thread UNF-2A Max ft-lbs

Max N-m

-2

5/16" - 24

6-7 8-9

-3

3/8" - 24

8-9 11-12

-4

7/16" - 20

13-15 18-20

-5

1/2" - 20

17-19 23-26

FIELD LOADER S-DRIVE – PORTABLE GRAIN BELT CONVEYOR 4. APPENDIX

Loading...

Loading...