Chapter 8: Maintenance 175

Unscheduled Maintenance

Maintenance

Procedure

Description When to Perform

Cleaning

external

surfaces

Keeps surfaces free from salt buildup

1 Dampen a cloth with cleaning

solution (page 169) and wipe dried

sheath fluid from surfaces.

2 Wet a fresh cloth with DI water and

wipe surfaces to prevent bleach

corrosion.

3 Wipe surfaces with a clean, dry cloth.

Whenever needed

Cleaning the

air filter

Removes dust and debris impeding

air flow

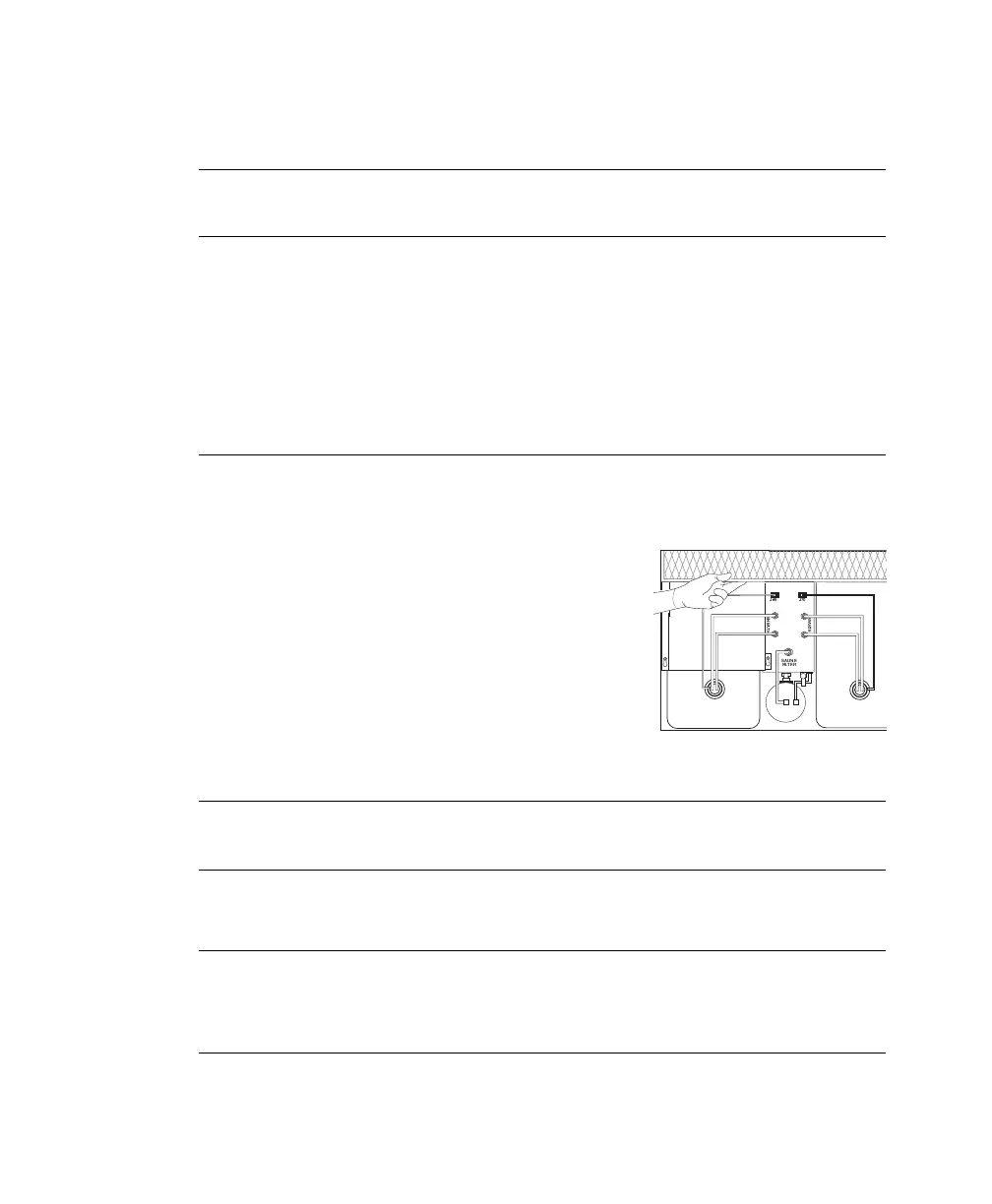

1 Turn off power; open fluidics drawer.

2 Grasp filter edges and pull gently to

slide out.

3 Vacuum the filter or hold it under

running tap water to clean. Allow it

to dry completely before reinstalling.

4 Reinstall the filter, ensuring arrows

on edge of filter point up. Align right

edge against spring clips in slide rail,

and push forward slowly.

5 Close the fluidics drawer.

Inspect periodically and

clean when dirty

Priming the

fluidics

Removes bubbles from flow cell

See page 58.

When needed during daily

startup

Replacing the

Bal Seal

Replaces worn Bal seal

See page 176.

When seal becomes worn or

cracked or sample tubes will

not pressurize

Replacing the

sample O-ring

Replaces worn sample O-ring

See page 178.

When droplets form at the

end of the SIT when the

droplet containment

vacuum is operating

Loading...

Loading...