141 S850 Operation & Maintenance Manual

HYDRAULIC / HYDROSTATIC SYSTEM

Checking And Adding Fluid

Check the hydraulic / hydrostatic fluid level every day

b

efore starting the work shift.

Park the loader on a level surface, lower the lift arms and

p

lace the attachment flat on the ground or tilt the Bob-

Tach fully back if no attachment is installed.

Stop the engine.

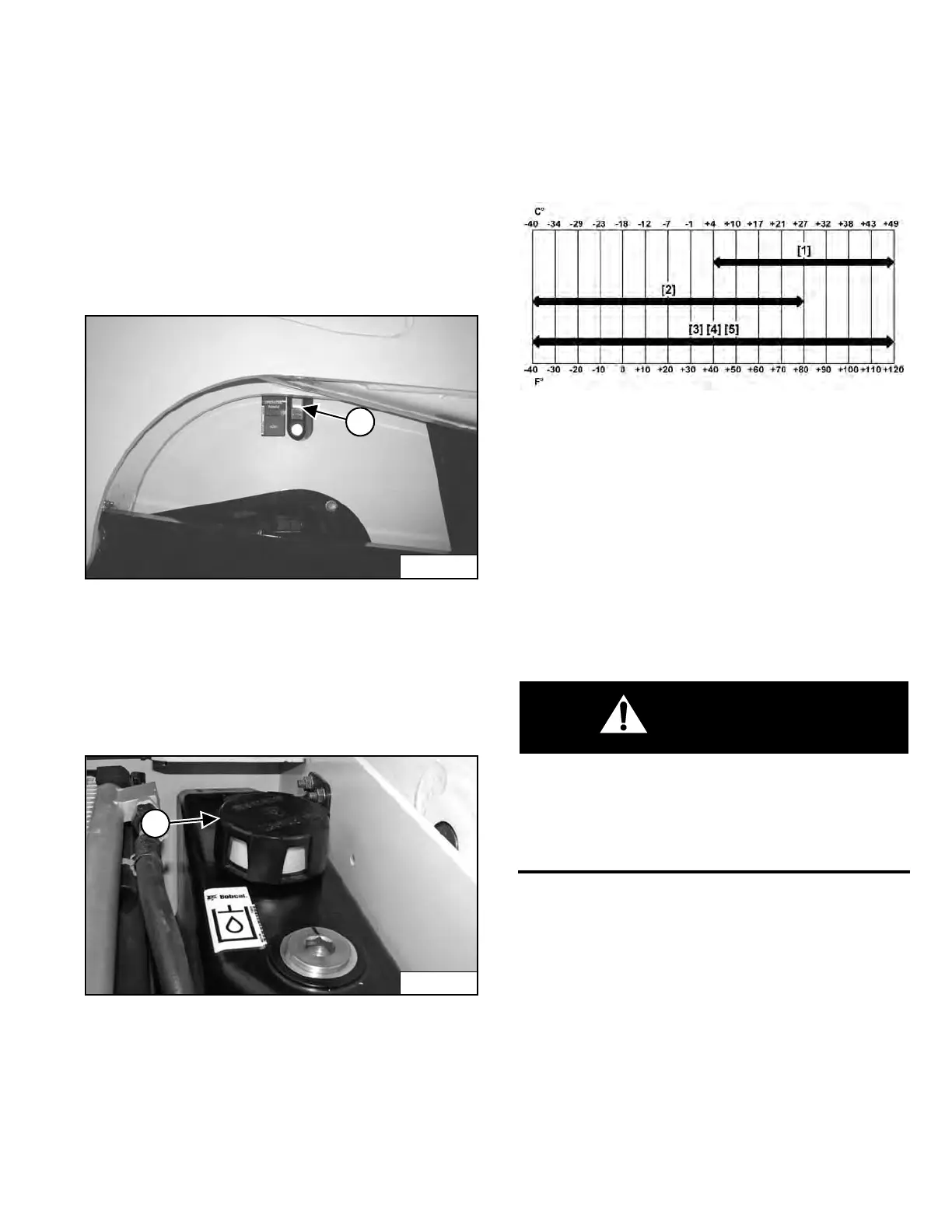

Figure 226

Check the fluid level in the sight gauge (Item 1)

[Figure 226]. Keep the fluid level within the operating

range.

Remove the rear grille. (See REAR GRILLE on Page

117.)

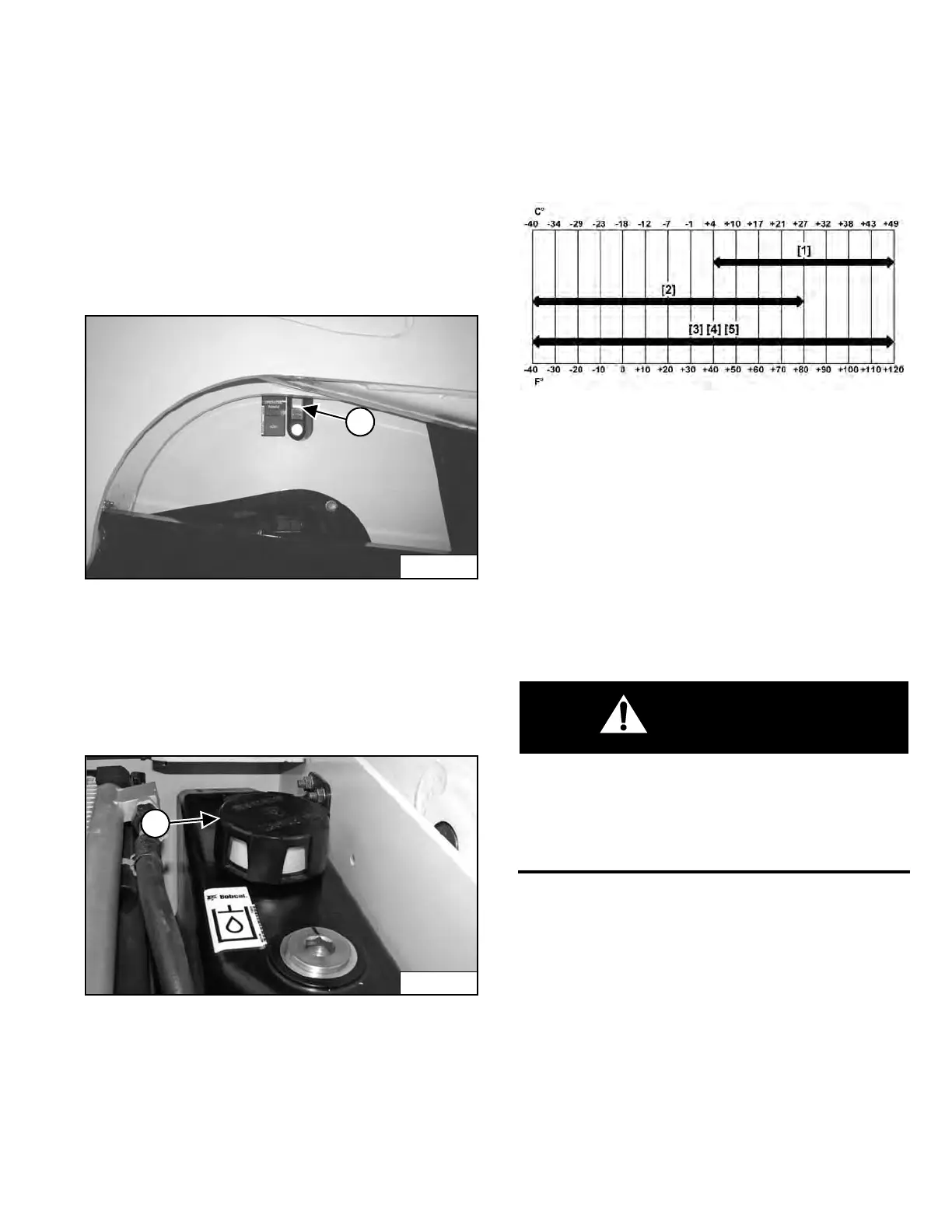

Figure 227

Remove the fill cap (Item 1) [Figure 227].

Add fluid as needed to bring the level within the operating

r

ange in the sight gauge (Item 1) [Figure 226].

Install the fill cap (Item 1) [Figure 227] and install the

rear grille.

Hydraulic / Hydrostatic Fluid Chart

Figur

e 228

HYDRAULIC / HYDROSTATIC FLUID

RECOMMENDED ISO VISCOSITY GRADE (VG)

AND VISCOSITY INDEX (VI)

TEMPERATURE RANGE ANTICIPATED

DURING MACHINE USE

[1] VG 100; Minimum VI 130

[2] VG 46; Minimum VI 150

[3] BOBCAT All-Season Fluid

[4] BOBCAT Synthetic Fluid

[5] BOBCA

T Biodegradable Hydraulic / Hydrostatic

Fluid (Unlike biodegradable fluids that are vegetable

based, Bobcat biodegradable fluid is formulated to

prevent oxidation and thermal breakdown at operating

temperatures.)

Use only recommended fluid in the hydraulic system

[Figure 228]. (See Hydraulic System on Page 199.)

AVOID INJURY OR DEATH

Always clean up spilled fuel or oil. Keep heat, flames,

sparks or lighted tobacco away from fuel and oil.

Failure to use care around combustibles can cause

explosion or fire.

W-2103-0508

Dealer Copy -- Not for Resale

Loading...

Loading...