72 S850 Operation & Maintenance Manual

HYDRAULIC CONTROLS (CONT’D)

High-Flow Hydraulics Operation

This machine may be equipped with High-Flow

Hydr

aulics.

The High-Flow function provides ad

ditional hydraulic fluid

flow to the system to operate an attachment that requires

more hydraulic flow. (EXAMPLE: High-Flow Planer)

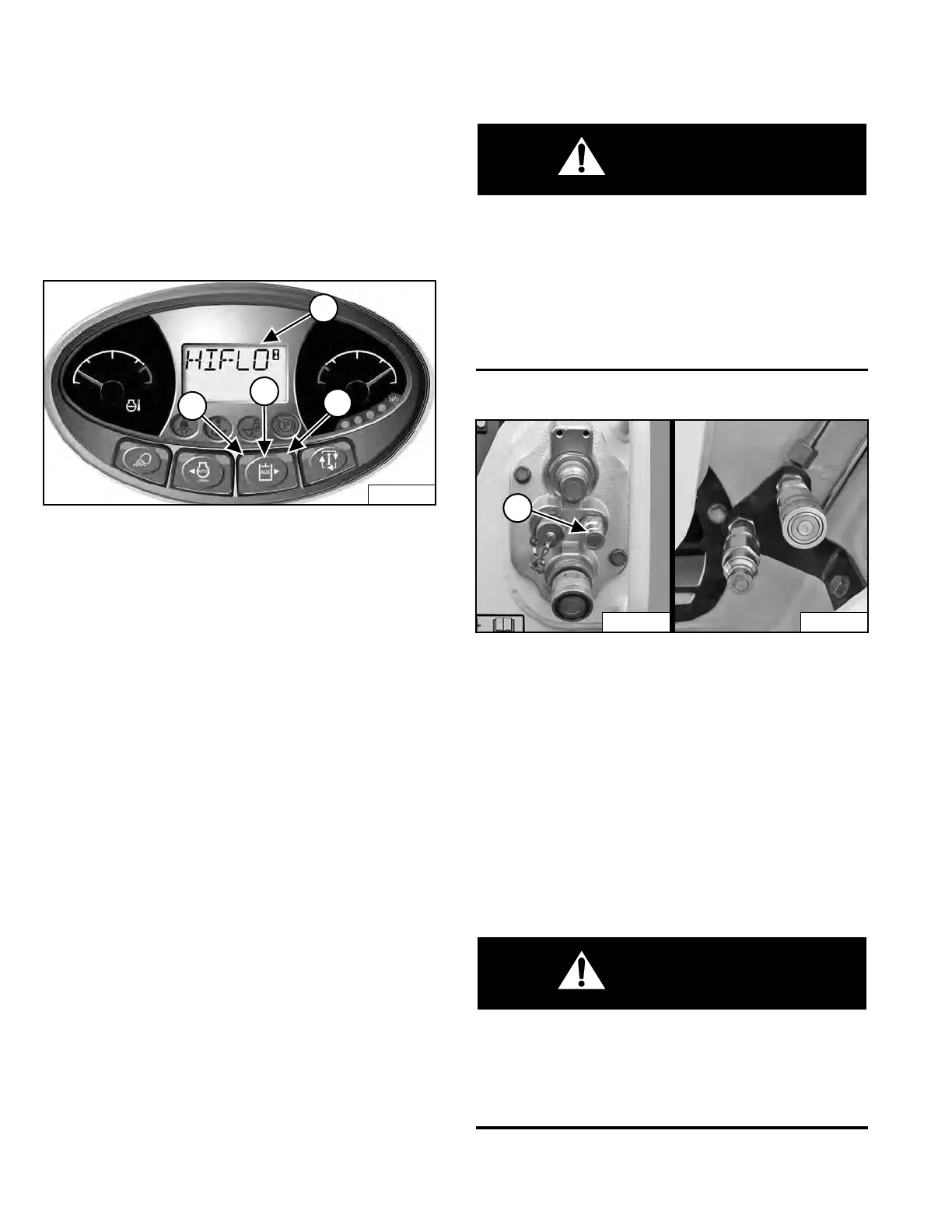

Figure 88

Press the Auxiliary Hydraulics b

utton (Item 2) once to

activate the auxiliary hydraulics. The light (Item 1)

[Figure 88] is ON.

Press the Auxiliary Hydraulics b

utton (Item 2) a second

time to activate high-flow auxiliary hydraulics. Both lights

(Items 1 and 3) are ON. [HIFLO] (Item 4) [Figure 88] will

appear briefly in the data display.

Press the Auxiliary Hydraulics button (Item 2) a third time

to deactiv

ate auxiliary hydraulics. Both lights (Items 1 and

3) [Figure 88] are OFF.

Attachments That Automatically Enable High-Flow

Hydraulics:

Press button once to activate auxiliary hydraulics and

high-flow, both lights are ON; second button press will

deactivate high-flow hydraulics, right light is OFF;

third button press will deactivate auxiliary hydraulics,

both lights are OFF.

Attachments That Automatically Disable High-Flow

Hydraulics:

Press button once to activate auxiliary hydraulics, left

light is ON; second button press will not activate high-

flow hydraulics, right light is ON briefly and turns OFF;

third button press will deactivate auxiliary hydraulics,

both lights are OFF.

NOTE: See attachment Operation & Maintenance

Manual for more information.

Quick Couplers

AVOID INJURY OR DEATH

Diesel fuel or hydraulic fluid under pressure can

penetrate skin or eyes, causing serious injury or

death. Fluid leaks under pressure may not be visible.

Use a piece of cardboard or wood to find leaks. Do

not use your bare hand. Wear safety goggles. If fluid

enters skin or eyes, get immediate medical attention

from a physician familiar with this injury.

W-2072-0807

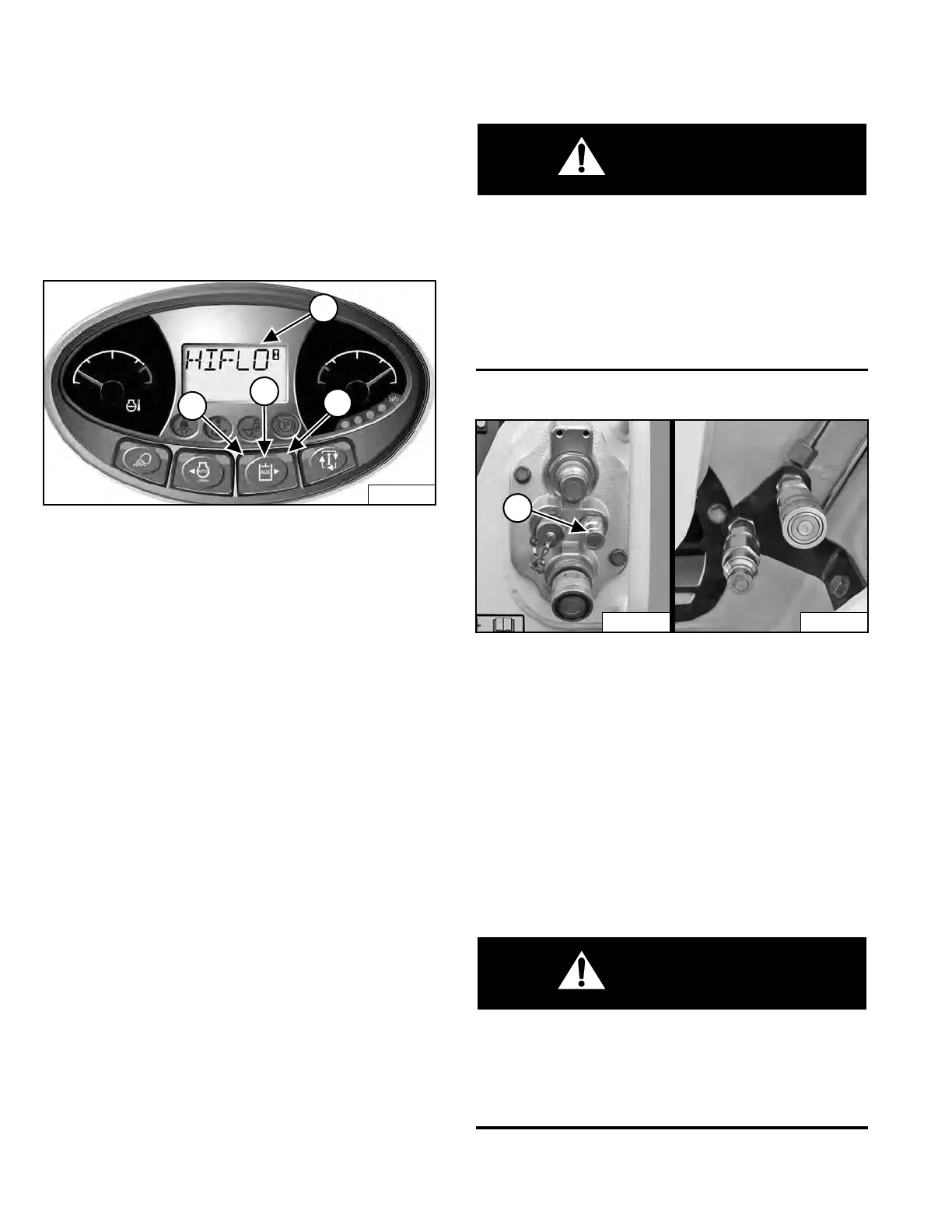

Figure 89

To Connect: Remove dirt or debris from the surface of the

male and female couplers, and from the outside diameter

of the male couplers. Visually check the couplers for

corroding, cracking, damage, or excessive wear. If any of

these conditions exist, the coupler(s) [Figure 89] must

be replaced.

Install the male couplers into the f

emale couplers. Full

connection is made when the ball release sleeves slide

forward on the female couplers. Some attachments may

have a case drain that needs to be connected to the

small quick coupler (Item 1) [Figure 89].

To Disconnect: Hold the male

couplers. Retract the

sleeves on the female couplers until couplers disconnect.

AVOID BURNS

Hydraulic fluid, tubes, fittings and quick couplers

can get hot when running machine and attachments.

Be careful when connecting and disconnecting quick

couplers.

W-2220-0396

Dealer Copy -- Not for Resale

Loading...

Loading...