C-19

Scanner

®

2000 microEFM Appendix C

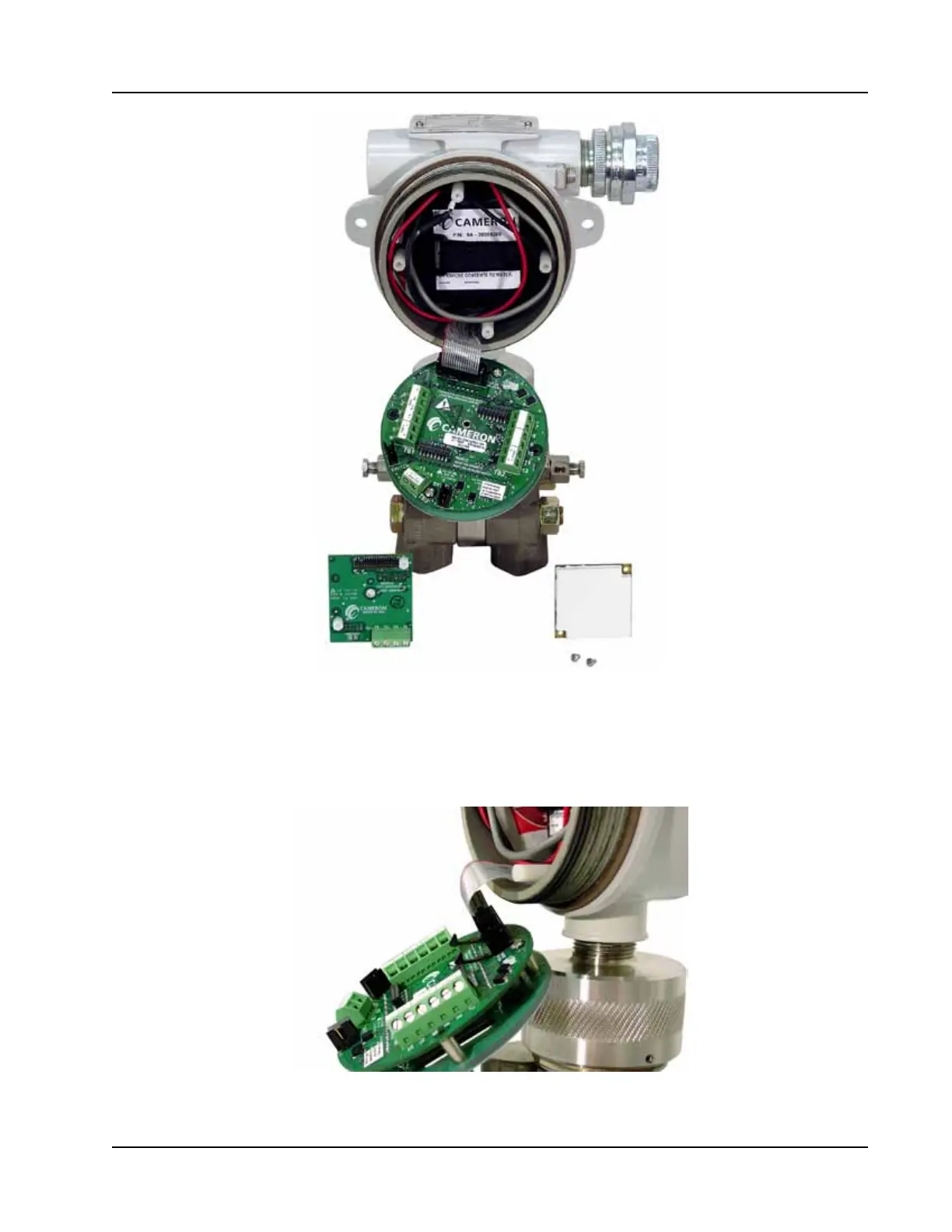

Figure C.11—Removal of the eldbus interface board

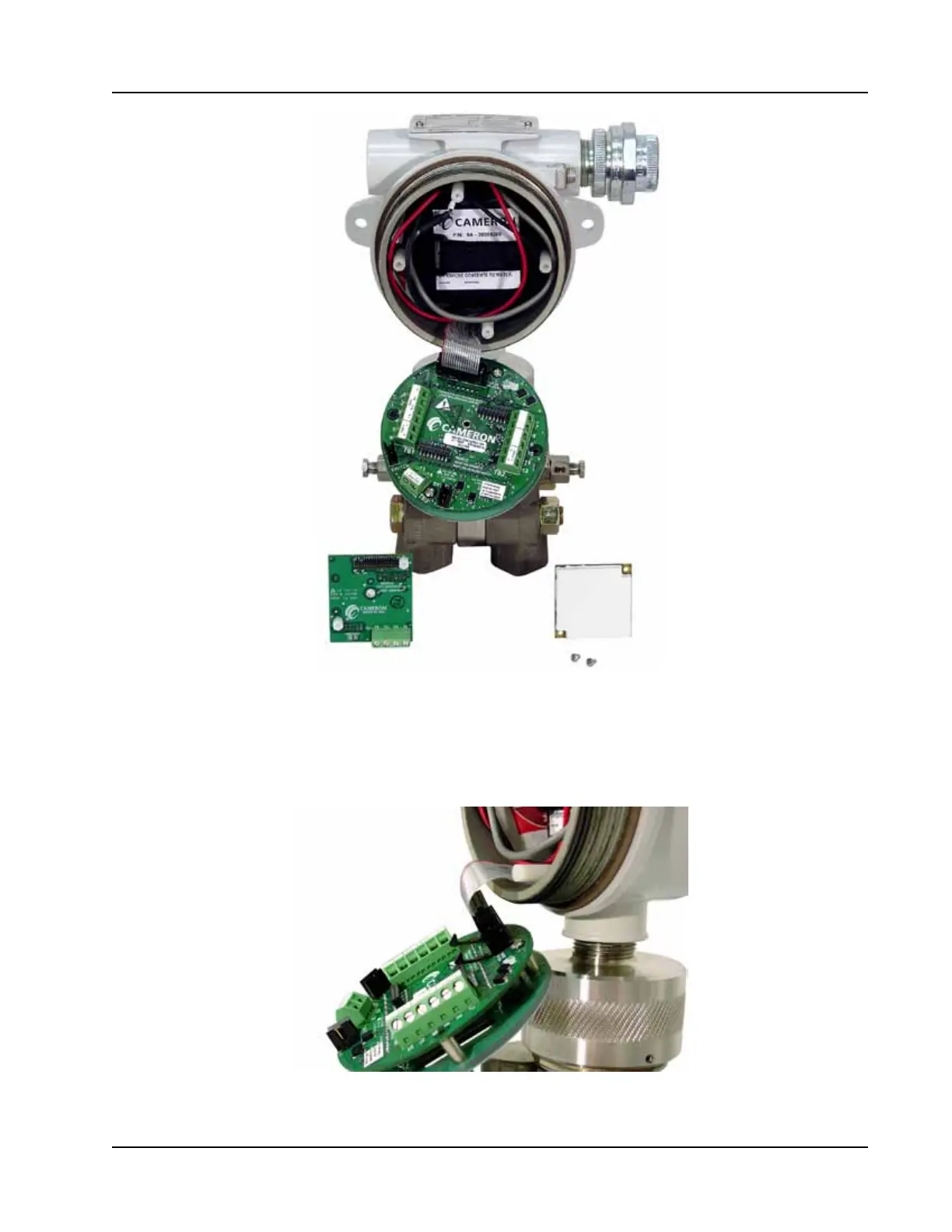

10. Disconnect the sensor ribbon cable from the J5 connector on the main board as follows:

a. Lift the latch from the black clip securing the ribbon cable (Figure C.12).

b. When the latch is fully open, the ribbon cable will release freely.

Figure C.12—Latch securing the ribbon cable

Loading...

Loading...