FC 300 Design Guide

Introduction to FC 300

Size Brake active Warning before cut out Cut out (trip)

FC 301 / 302 3 x 200-240 V 390 V (UDC) 405 V 410 V

FC 301 3 x 380-480 V 778 V 810 V 820 V

FC 302 3 x 380-500 V 810 V 840 V 850 V

FC 302 3 x 525-600 V 943 V 965 V 975 V

NOTE

Check that the brake resistor can cope with a voltage of 410 V, 820 V, 850 V or

975 V - unless Danfoss brake resistors are used.

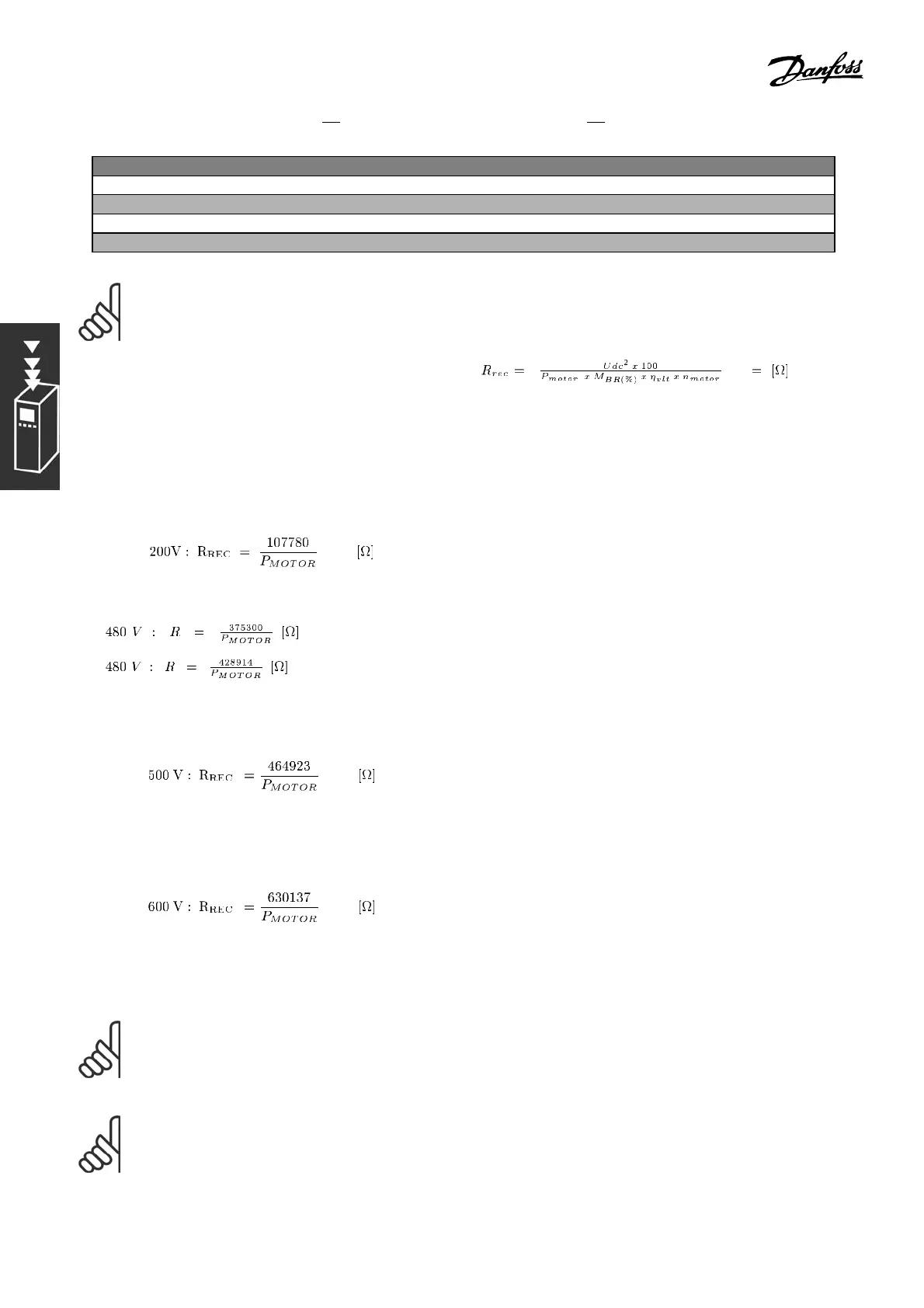

Danfoss recommends the brake resistance R

REC

,i.e.

one that guarantees that the adjusta

ble frequency

driveisabletobrakeatthehighestbrakingtorque

(M

br

)of160%. Theformulacanbewrittenas:

η

motor

is typically at 0.90 η

VLT

is typically at 0.98

For the 200 V, 48 0 V, 500 V and 600 V adjusta ble frequency drives, R

REC

at 160% braking torque is written as:

1.

2.

1. For FC 300 adjustab le freque n cy drives ≤ 10 HP [7.5 kW] shaft output

2. For FC 300 adjustab le frequency drives > 10 HP [7.5 kW] shaft output

NOTE

The resistor brake circuit r esistance selected should not be higher than that recommended by

Danfoss. If a brake resistor with a higher ohmic value is selected, the 160% braking torque may not

be achieved because there is a risk that the adjustable frequency drive cuts out for safety reasons.

NOTE

If a short circuit in the brake transistor occurs, power dissipa tion in the brake resistor is only

prevented by u sing a line s witch or contactor to disconnect the AC line for the adjustab le frequency

drive. (The contactor can be controlle d by the adjustable frequency drive).

48

MG.33.B6.22 - VLT is a registered Danfoss trademark

Loading...

Loading...