Design Guide | iC7 Series Liquid-cooled System Modules

6.3 Coolant

6.3.1 Quality Requirements for the Purified Water

NOTICE

DAMAGE TO SYSTEM FROM THE USE OF HYDROCARBONS

Hydrocarbons damage the rubber seals of the cooling system.

l Do not use hydrocarbons (for example mineral oil) as coolant. Do not mix hydrocarbons to coolant.

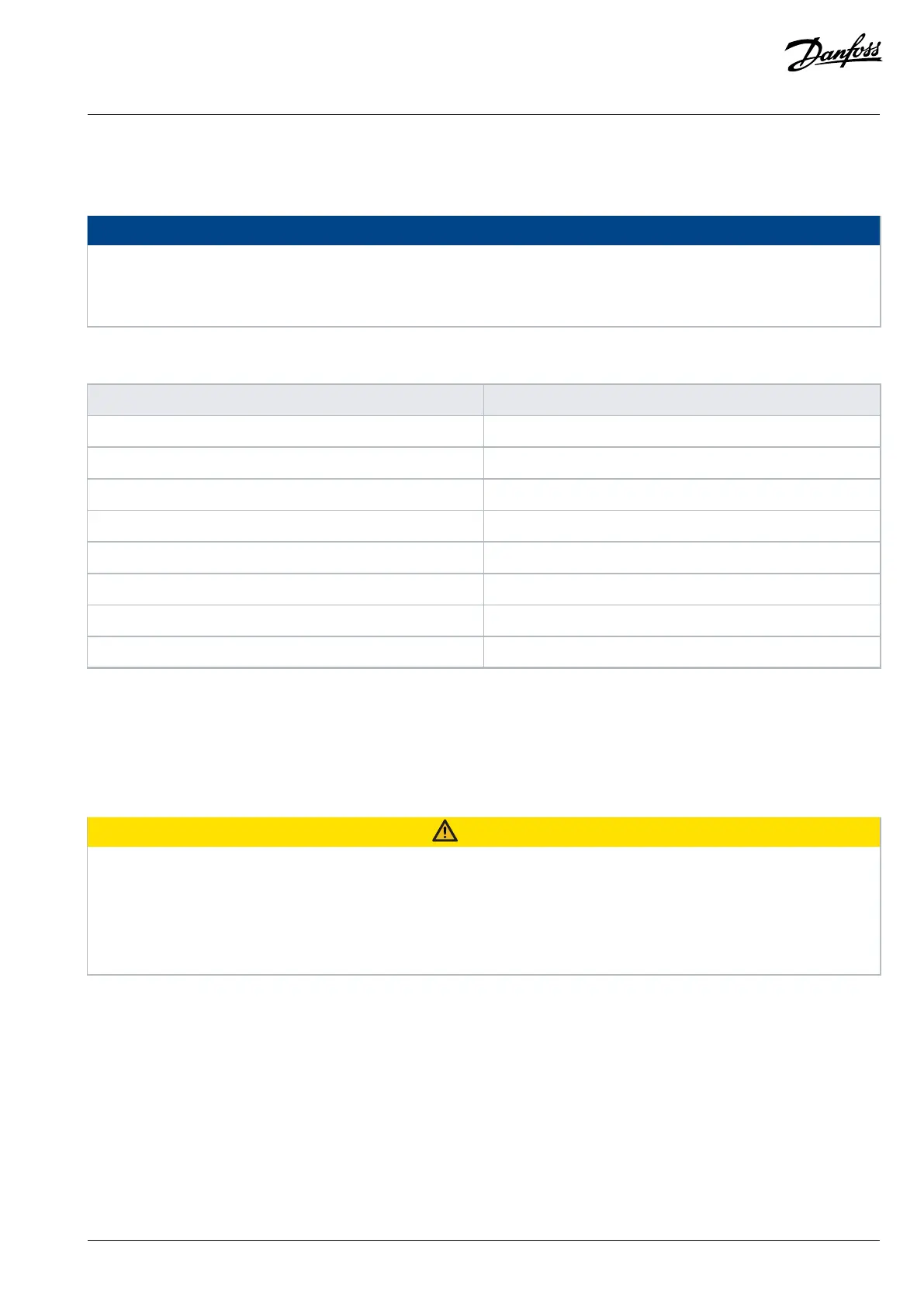

Table 7: Requirements for the Purified Water

Property Required value

pH 6...8

Chlorides ≤ 25 ppm

Sulphate ions ≤ 25 ppm

Maximum particle size ≤ 50 µm

Total dissolved solids ≤ 200 ppm

Total hardness (CaCO

3

) 3…4.6 dH° (53…80 ppm)

Hydrogen carbonate ≤ 50 ppm

Electrical conductivity ≤ 500 µS/cm

6.3.2 Purified Water as Coolant

Purified water can be used as coolant if there is no risk of freezing. Freezing water permanently damages the cooling system. Purified

water is demineralized, deionized, or distilled water.

Always use an inhibitor Cortec VpCI-649 with 1.0% of volume with purified water.

CAUTION

CORROSION HAZARD WITH DRINKING WATER

Some components are made of aluminum, which has limited corrosion resistance against high chloride concentrations. Drinking

water can have a chloride concentration of 250 ppm, which increases the aluminum corrosion rate. High chloride concentration

exposes aluminum especially to pitting corrosion which can damage the system relatively quickly.

l Use purified (demineralized, deionized, or distilled) water with corrosion inhibitors.

6.3.3 Antifreeze Mix as Coolant

The following antifreeze products are a good general solution for liquid cooling since they provide freeze protection and corrosion

protection.

The allowed antifreeze coolants are the following ethylene glycols and propylene glycols.

Ethylene glycols

l DOWCAL 100

l Clariant Antifrogen N

Danfoss Drives Oy © 2024.03 AJ475942178716en-000101 / 172K2848A | 39

Loading...

Loading...