Design Guide | iC7 Series Liquid-cooled System Modules

7 Electrical Installation

7.1 Fuses of the Drive System

The drive system must be equipped with ultra-rapid AC fuses to limit the damage of the drive system. The fuse sizes are based on Mersen

aR fuses. Use these fuses to achieve sufficient protection against short circuits. Select the supply cable protection according to local

regulations.

DC fuses must be installed for parallel units where necessary to limit the damage of the drive system. Each DC supply line must be

equipped with fuses. The DC fuses are provided with the delivery as option. Do not replace the DC fuses with any other types.

The protective devices must be integrated within the same overall assembly as the system module.

The fuse tables can be found in 10.5.1 List of Fuse Size Information.

Fuse ratings are based on a maximum ambient temperature of 60 °C and a minimum airflow of 2 m/s around the fuse.

To ensure fuse performance, make sure that available supply short circuit current is sufficient. See minimum required values (I

cp,mr

) at the

fuse location in 10.5.2 AC Fuses for AFE or GC 525–690 V AC, IP00/Open Type.

7.2 Guidelines for DC Connections of System Modules

The DC busbars and cabling must be dimensioned according to local installation regulations and codes, so that the cross-section is

sufficiently large for the current flowing at the relevant point. See the DC current ratings in 10.6.1 List of Current Rating Information.

The DC busbar itself must be designed to attain the lowest possible inductance.

Adequate fuse protection for the drive configuration must be provided on the line side and on the DC side. The power cables and

busbars must be dimensioned with sufficient thermal and mechanical strength to handle short circuits in the system. See the fuse ratings

in 10.5.1 List of Fuse Size Information.

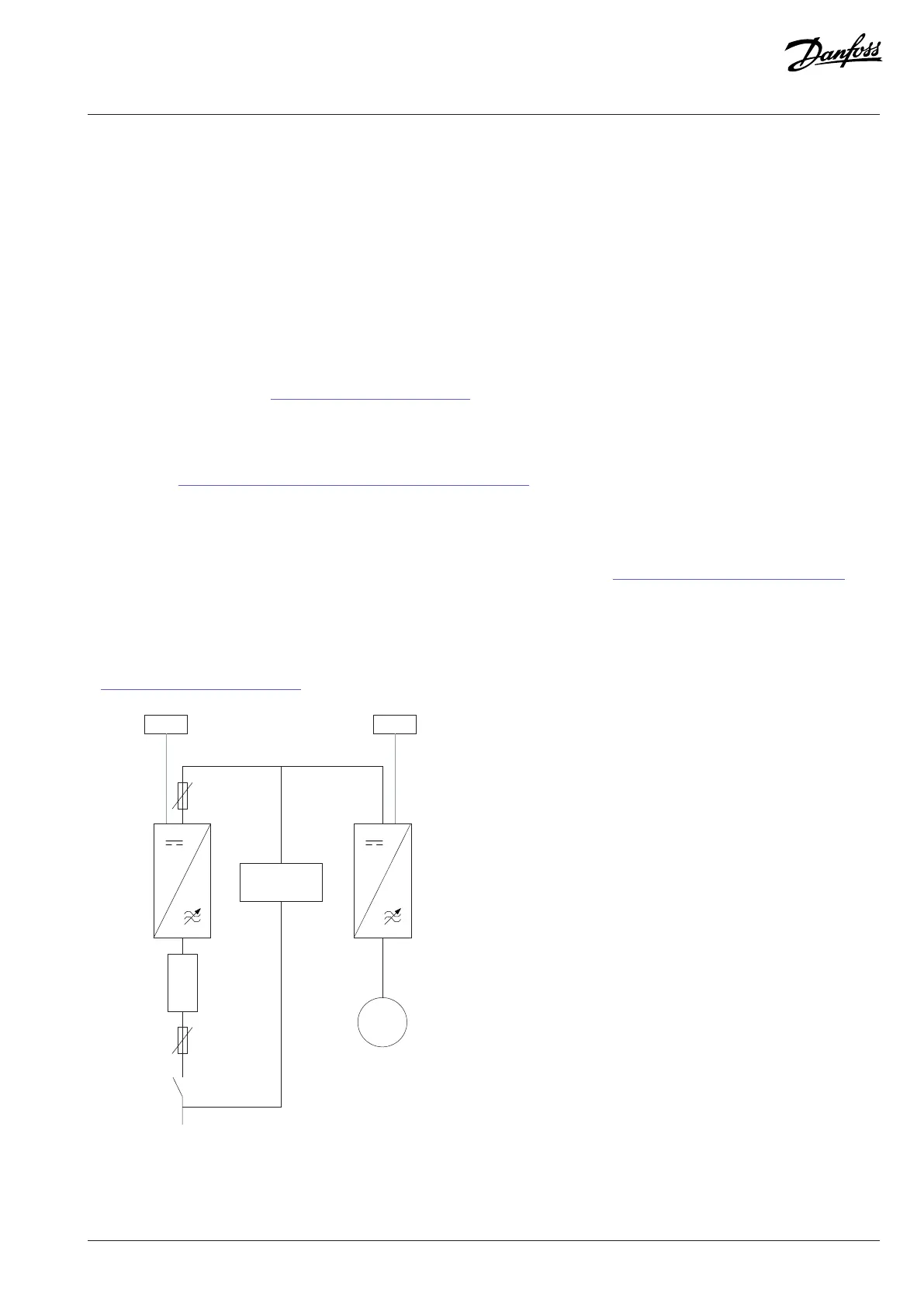

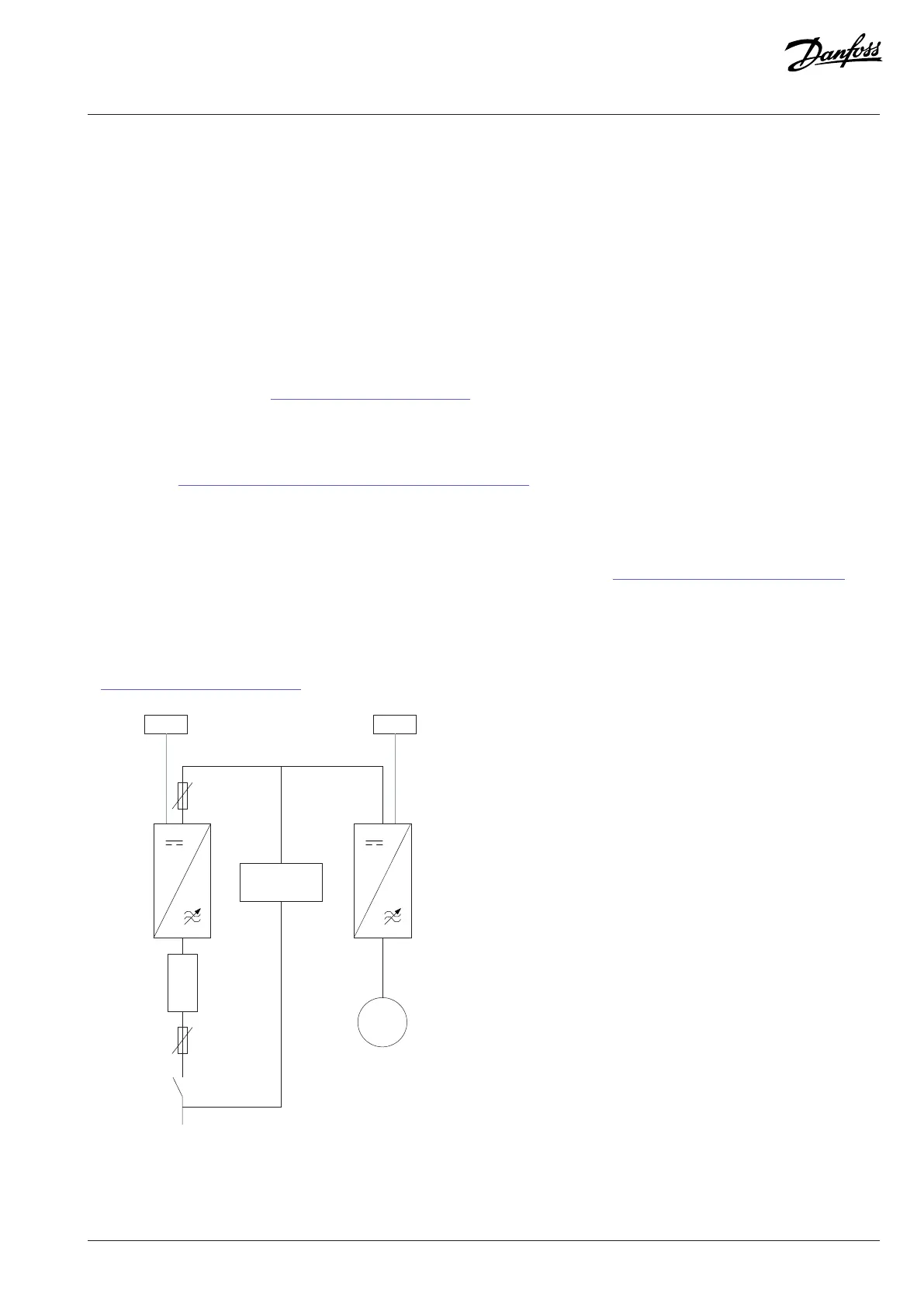

INU

power

unit

Pre-charging

circuit

Figure 56: DC Connections of Single Power Units

Danfoss Drives Oy © 2024.03 AJ475942178716en-000101 / 172K2848A | 65

Loading...

Loading...