Chapter 16 PLC Function ApplicationsMH300

16-10 CANopen Master control applications

Control of a simple multi-axis application is required in certain situations. If the device supports the

CANopen protocol, a MH300 can serve as the master in implementing simple control (position, speed,

homing, and torque control). The setting method comprises the following seven steps:

Step 1: Activating CANopen Master functions

1. Pr. 09-45=1 (initiates Master functions); restart power after completing setting, the status bar on the

KPC-CC01 digital keypad will display "CAN Master".

2. Pr. 00-02=6 reset PLC (please note that this action will reset the program and PLC registers to the

default values)

3. Turn power off and on again.

4. Use the KPC-CC01 digital keypad to set the PLC control mode as "PLC 2" (if a newly-introduced

drive is used, the blank internal PLC program will cause a PLFF warning code to be issued).

Step 2: Master memory settings

1. A

fter connecting the 485 communications cable, use WPL Soft to set the PLC status as Stop (if

the PLC mode has been switched to the "PLC 2" mode, the PLC status should already be Stop)

2. Set the address and corresponding station number of the slave station to be controlled. For

instance, if it is wished to control two slave stations (a maximum of 4 stations can be controlled

simultaneously), and the station numbers are 21 and 22, it is only necessary to set D2000 and

D2100 as 20 and 21, and then set D2200, D2300, D2400, D2500, D2600, and D2700 as 0. The

setting method involves use of the PLC's WPL editing software WPL as follows:

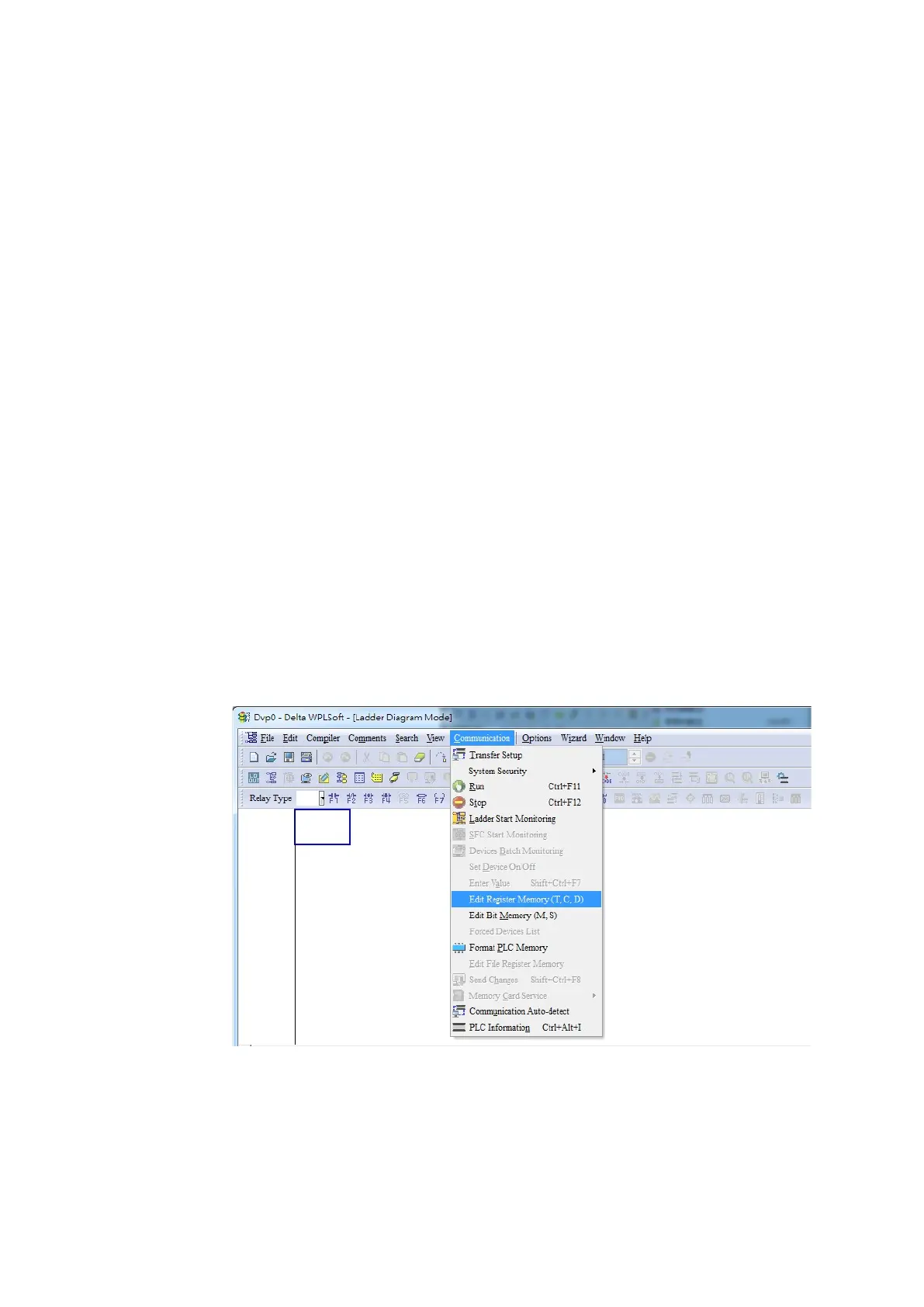

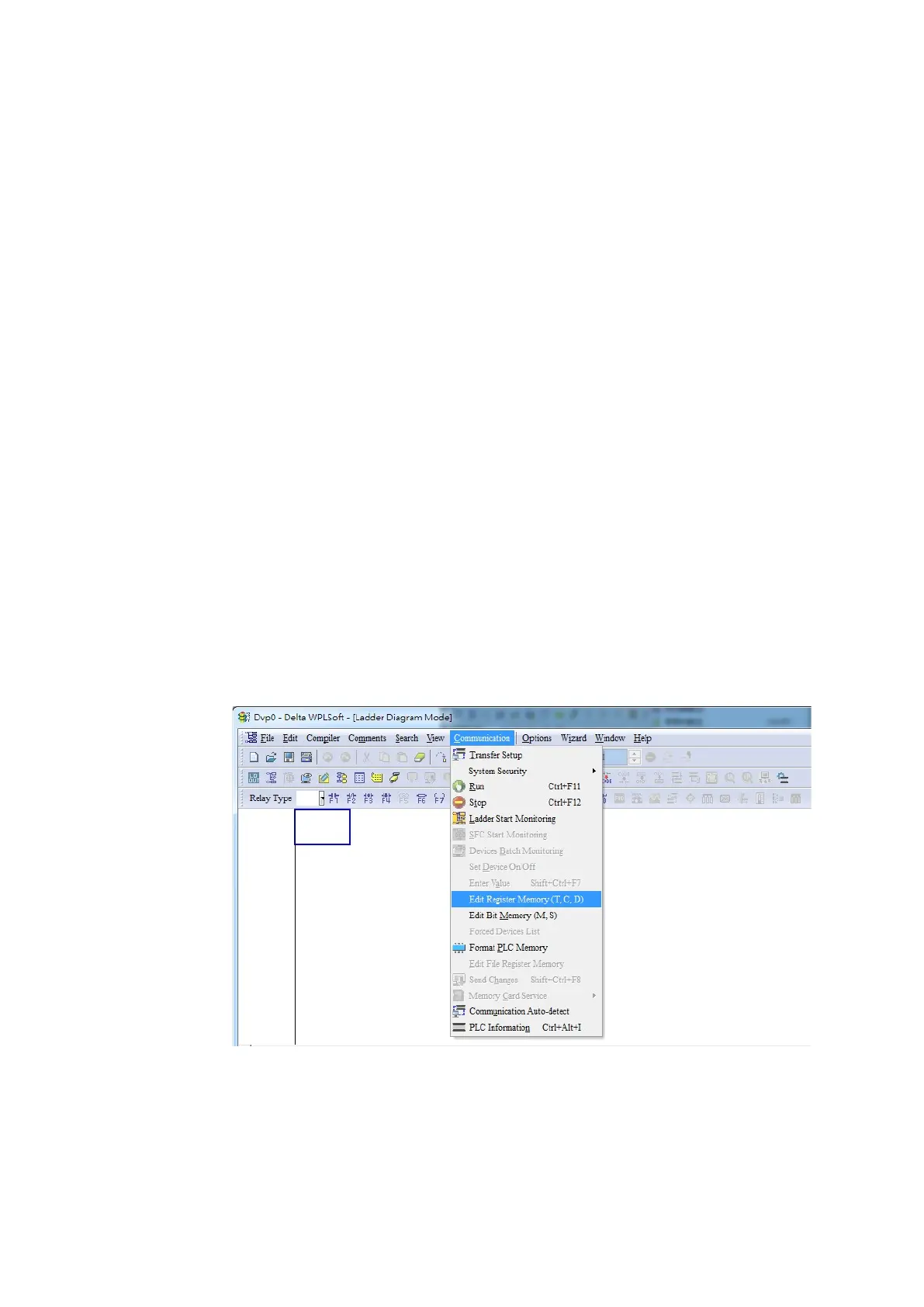

Open WPL and implement communications > register edit (T C D) function

Loading...

Loading...