Chapter 16 PLC Function ApplicationsMH300

16-5 Various PLC Device Functions

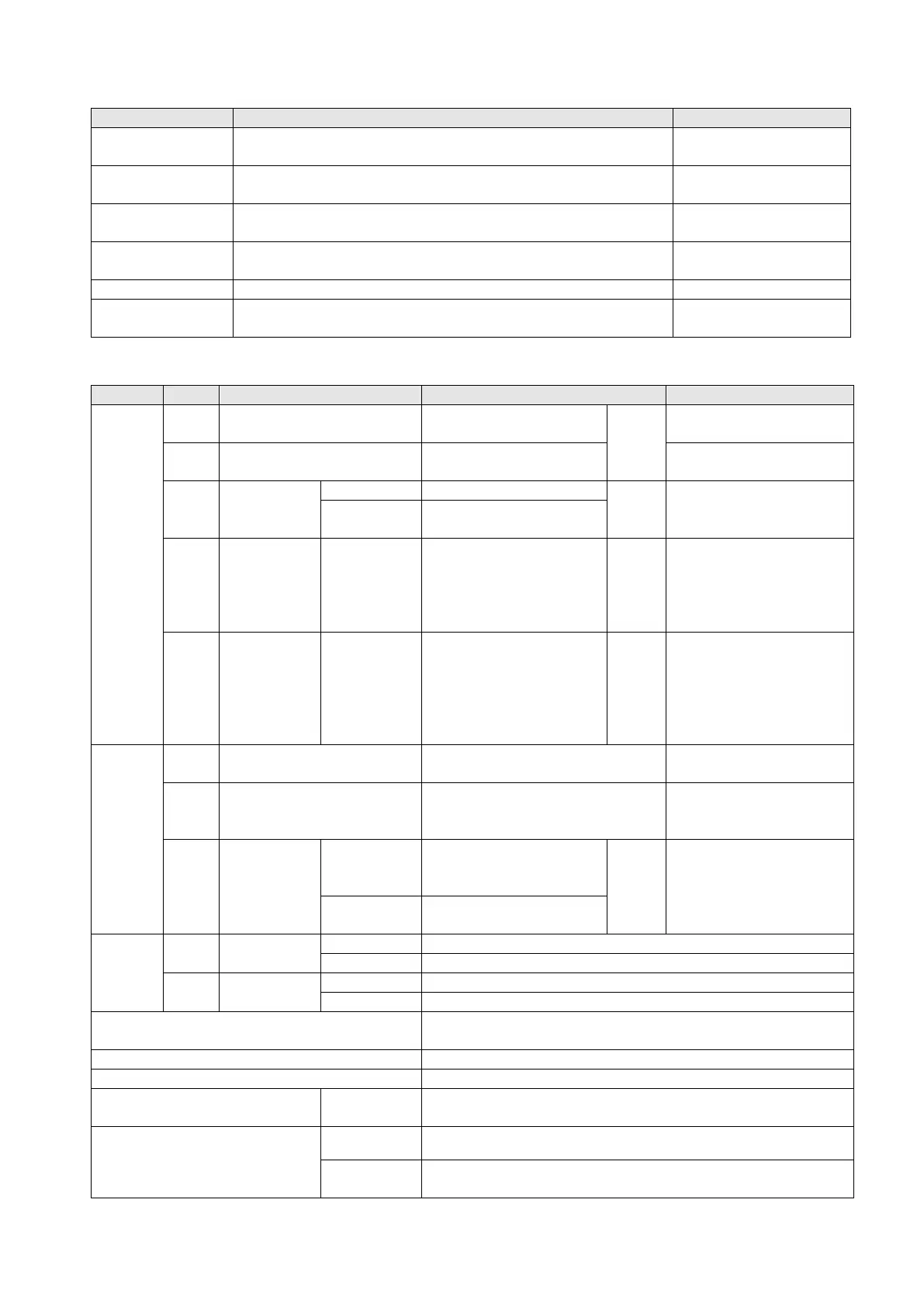

Algorithmic control

method

The program is stored internally, alternating back-and-forth

scanning method.

Input/output control

method

When the scan starts again after ending (after execution to the

END command), the input / output is immediately refreshed.

Algorithmic

processing speed

Basic commands (several μs)

Application command (1

to several tens of μs)

Command + ladder diagram

Digital input (X): 7, digital output (Y): 3

Analog input AI: 2, analog output AO: 1

Table 16-7

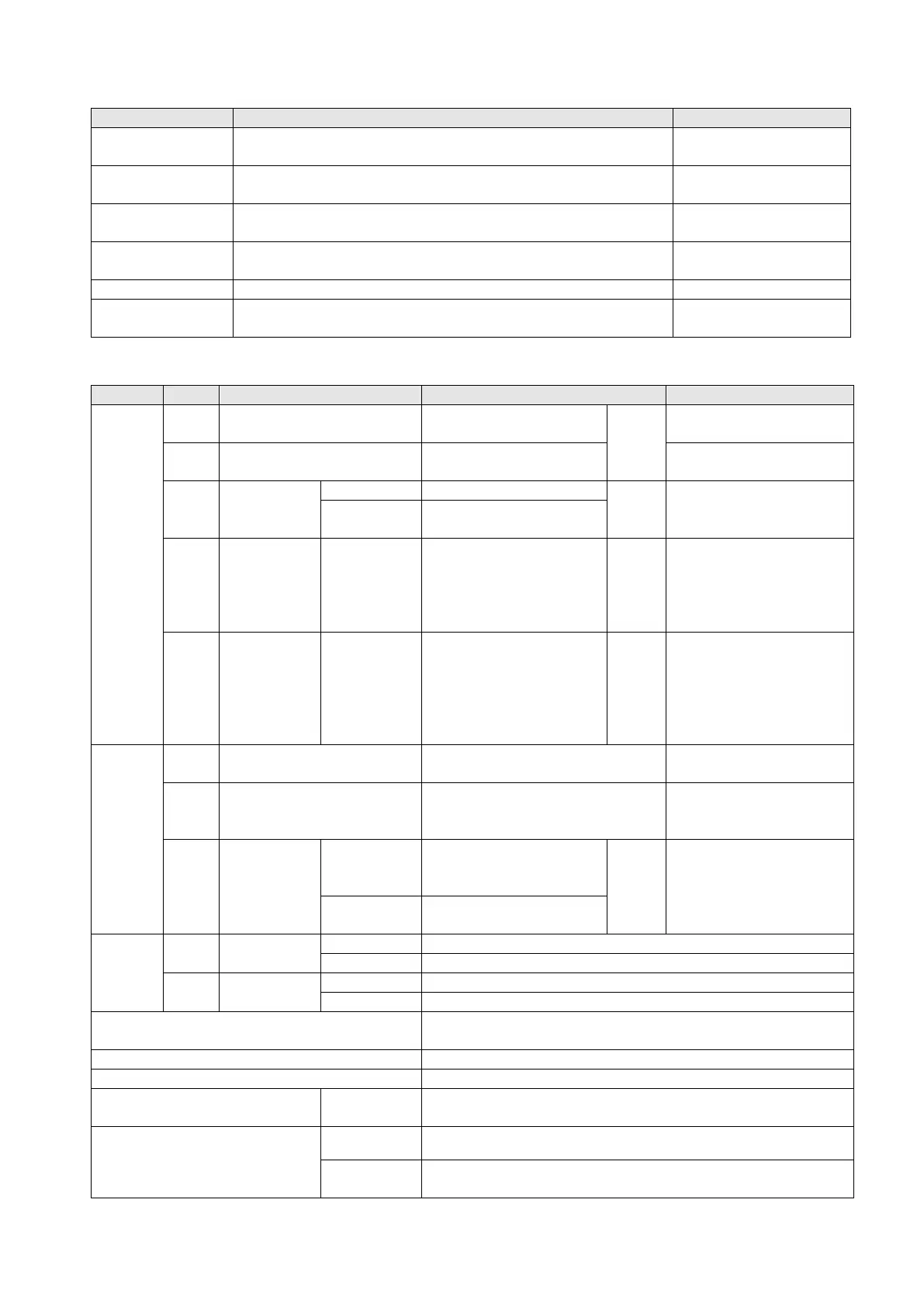

Relay bit

form

X External input relay

X0–X17, 16 points, octal

number

Total

32

points

Corresponds to external

input point

Y External output relay

Y0–Y17, 16 points, octal

number

Corresponds to external

output point

M

Auxiliary

Relay

1080

ON/OFF within the

T Timer 100 ms timer

T0–T59, 160 points

Total

160

points

Timers referred to by the

TMR command; T contact

with the same number

switches ON when the

C Counter

16-bit

counter,

general use

C0–C79, 80 points

Total

80

points

Counter referred to by the

CNT command; contact of

the C with the same

number switches ON

when the count is

Register

word

data

T Current timer value T0–T159, 160 points

The contact switches ON

when the time is reached.

C Current counter value C0–C79, 16-bit counter 80 points

switches ON when the

D

Data

Register

maintain

D0–D99, 100 points

Total

1020

points

Used as data storage

memory area

D100–D399, 300 points

D1000–D1619, 620 points

Constant

K Decimal

Setting Range: K-32,768–K32,767

Setting Range: K-2,147,483,648–K2,147,483,647

H Hexadecimal

Setting Range: H0000–HFFFF

Setting Range: H00000000–HFFFFFFFF

Serial communications port

(program write/read)

RS-485/USB/keypad port

Two built-in analog inputs and one analog output

One built-in (MI7 or MI6+MI7 ) 32-bit high-speed counter

Function expansion module

EMM-D33A; EMM-R2CA; EMM-R3AA; EMM-A22A

Communication expansion

module

Built-in CANopen (slave)

Table 16-8

Loading...

Loading...