Chapter 6 Control TerminalsMH300

6-1 Control Terminal Specifications

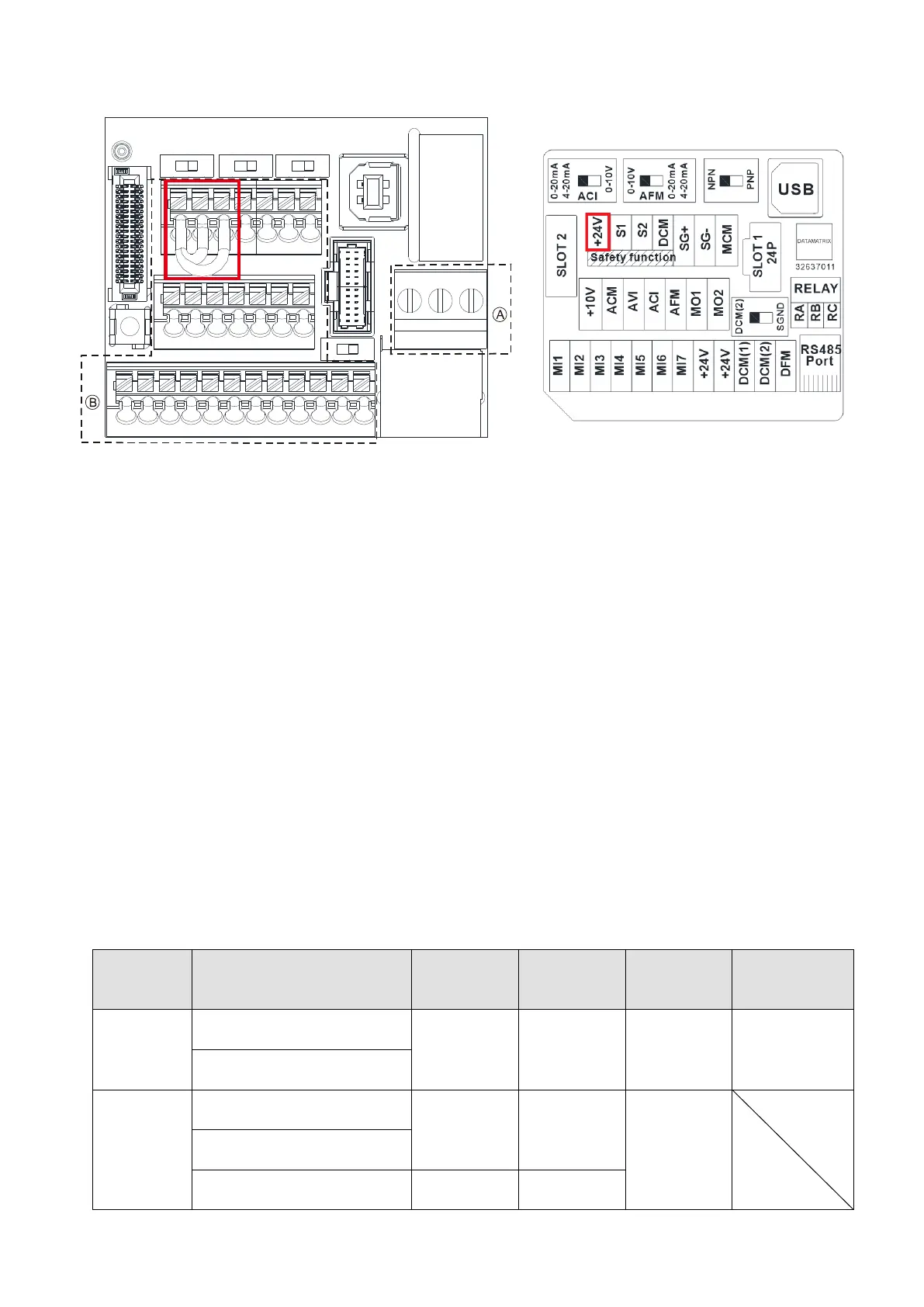

Fig. 6-6 Control Terminal Distribution Diagram

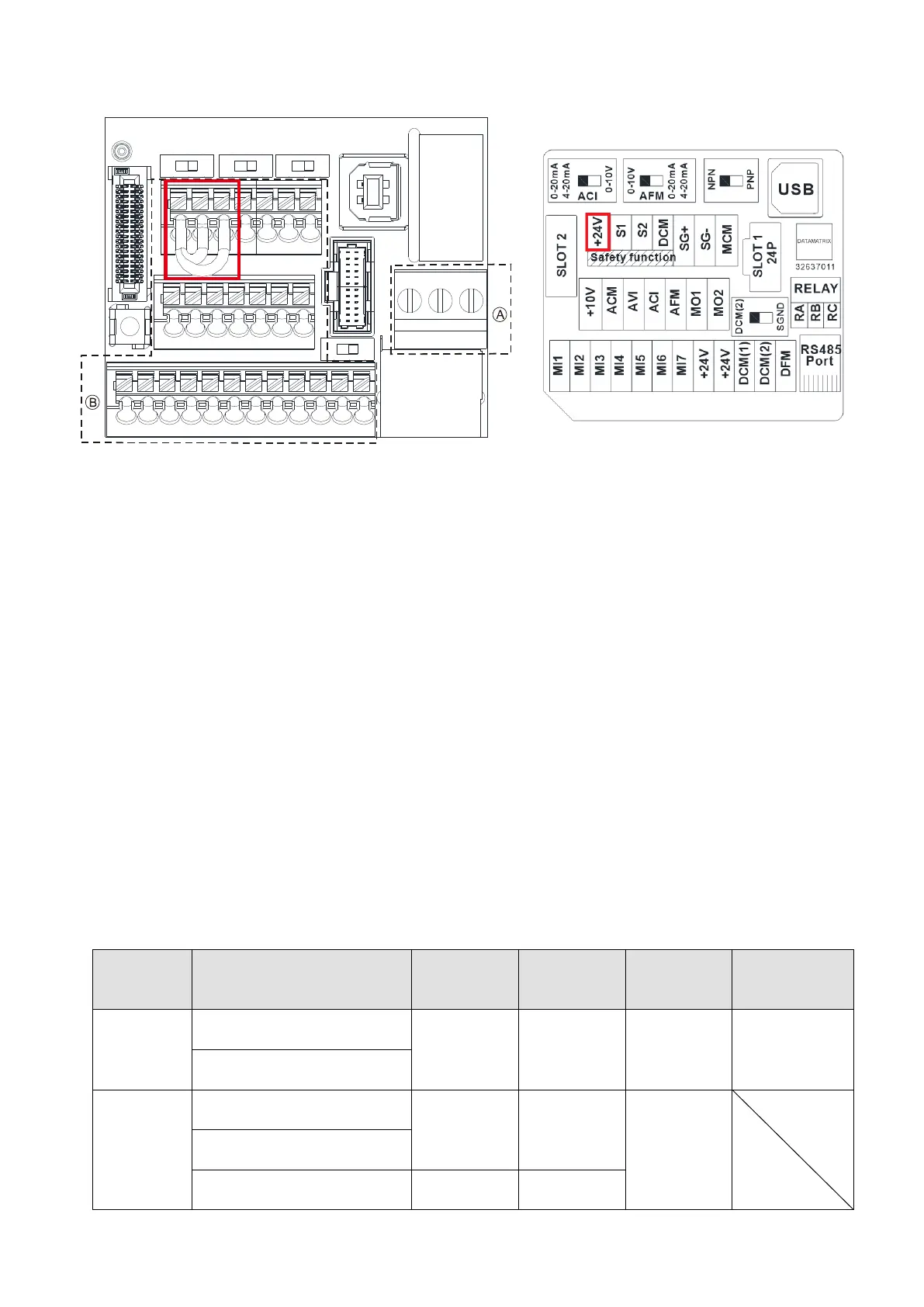

Fig. 6-7 Control Terminal Location Map

Wiring precautions:

The default condition is +24V / S1 / S2 shorted by jumper, as shown 1. in the Fig. 6-6. Refer to

Chapter 4 WIRING for more details

The +24V of safety function is for STO only, as shown 2. in the Fig. 6-7, and cannot be used for other

purpose.

The RELAY terminal uses the PCB terminal block (as shown area

○

A

in the Fig. 6-6):

1. Tighten the wiring with a 2.5 mm (wide) x 0.4 mm (thick) slotted screwdriver.

2. The ideal length of stripped wire at the connection side is 6–7 mm.

3. When wiring bare wires, make sure they are perfectly arranged to go through the wiring holes.

The Control terminal uses a spring clamp terminal block (as shown area

○

B

in the Fig. 6-6):

1. When removing wires, use the slotted screwdriver to press down the terminal, and the suggested

force is 1.5 kgf.

The specification of slotted screwdriver: 2.5 mm (wide) x 0.4 mm (thick).

2. The ideal length of stripped wire at the connection side is 9 mm.

3. When wiring bare wires, make sure they are perfectly arranged to go through the wiring holes.

Wir

ing Specifications of Control Terminal

Function

name

Conductor

Stripping

length (mm)

Maximum

wire gauge

Minimum

wire gauge

tightening

RELAY

Terminals

Conductor cross section

solid wire

6~7

1.5mm

2

(16AWG)

0.2 mm

2

(24AWG)

5 Kg-cm

(4.3 lb-in.)

(0.49 Nm)

Conductor cross section

stranded wire

Control

Terminals

Conductor cross section

solid wire

9

0.75mm

2

(18AWG)

0.2 mm

2

(24AWG)

Conductor cross section

stranded wire

Stranded with ferrules with

plastic sleeve

9

Loading...

Loading...