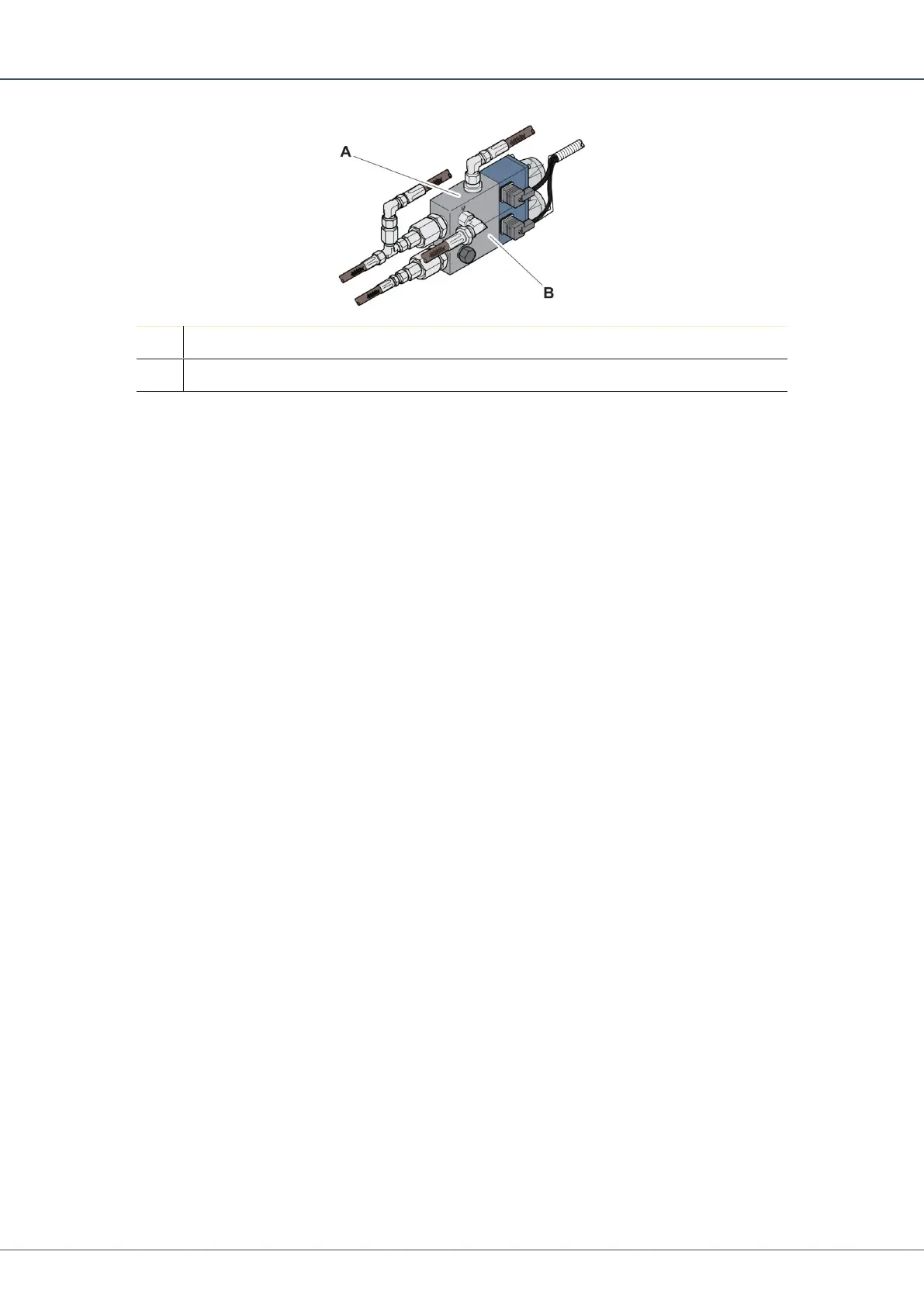

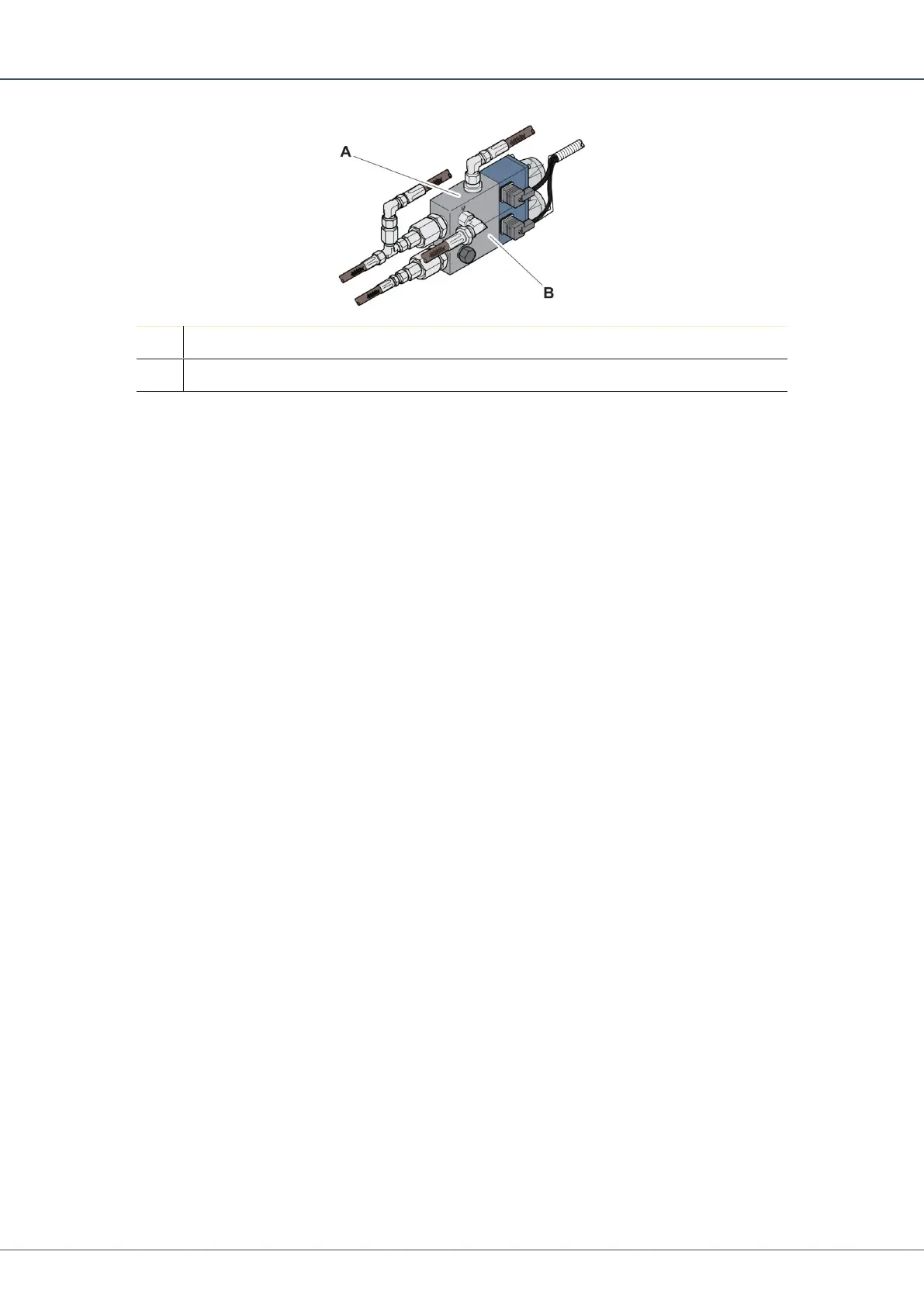

SmartROC T35/T40 10 Lubrication System for Rock Drill

54 No: 7026962571.1.7027002891 en-US

A Thread lubrication pump (ECG)

B Rock drill lubricating pump (ECL)

10.4 Drain Water Condensation from Lubrication Tank

n

Drain water from lubrication tank.

Loading...

Loading...