SmartROC T35/T40 18 Track Frames

111 No: 7026962571.1.7027002891 en-US

18 Track Frames

18.1 Check Tension of Crawler Tracks

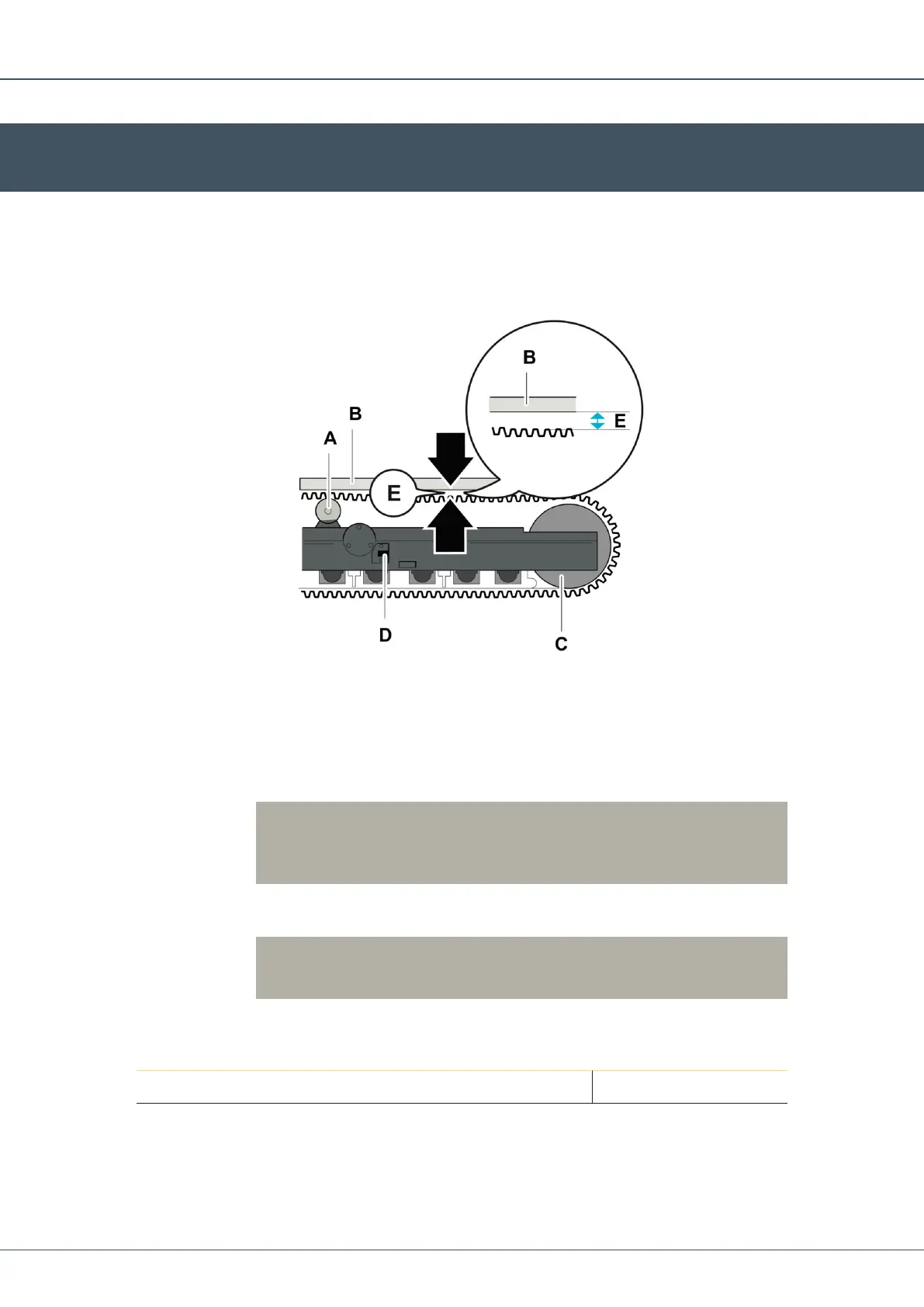

Track tension is checked between the front wheel (C) and carrier roller (A).

Precondition

p

The machine is parked on a flat and level surface.

p

Tracks are under normal load.

1.

Place a leveling board (B) on top of each track and maintain a clearance (E) between

them.

!

NOTE: If the tracks do not have a carrier roller (A), position the lev-

eling board between the end wheels with a maximum of 50 mm

(1.96 in) slack in the center.

2.

Fill grease through the nipple (D) to tension the track.

!

NOTE: Do not use this grease nipple during lubrication, it is used

only during this procedure.

3.

If the track tension becomes too tight, grease can also be drained from the tension

cylinder by loosening the nipple (D).

Clearance (E) 5–15 mm

Loading...

Loading...