Part 2: Maintenance 13. Protected Model Maintenance

205

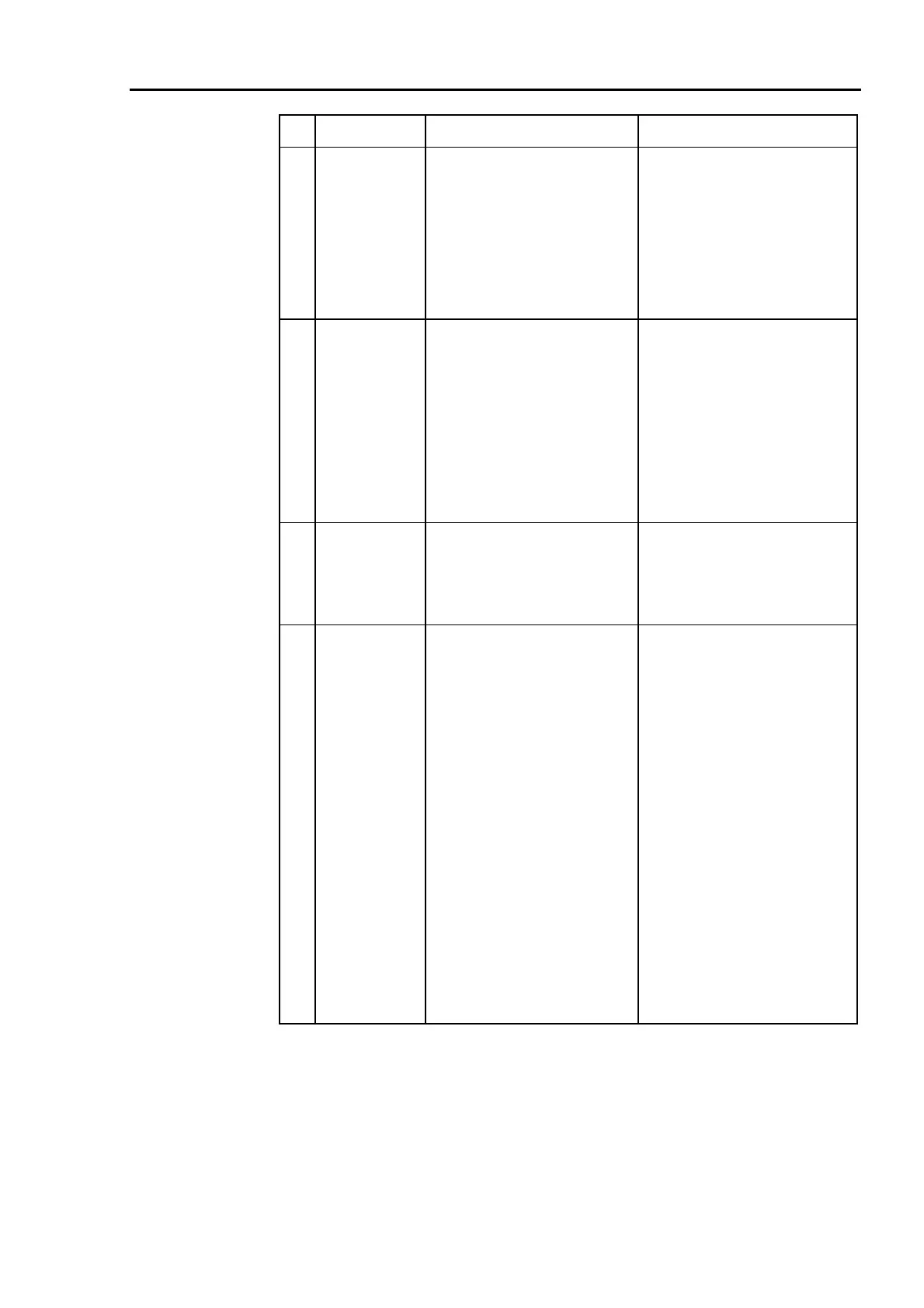

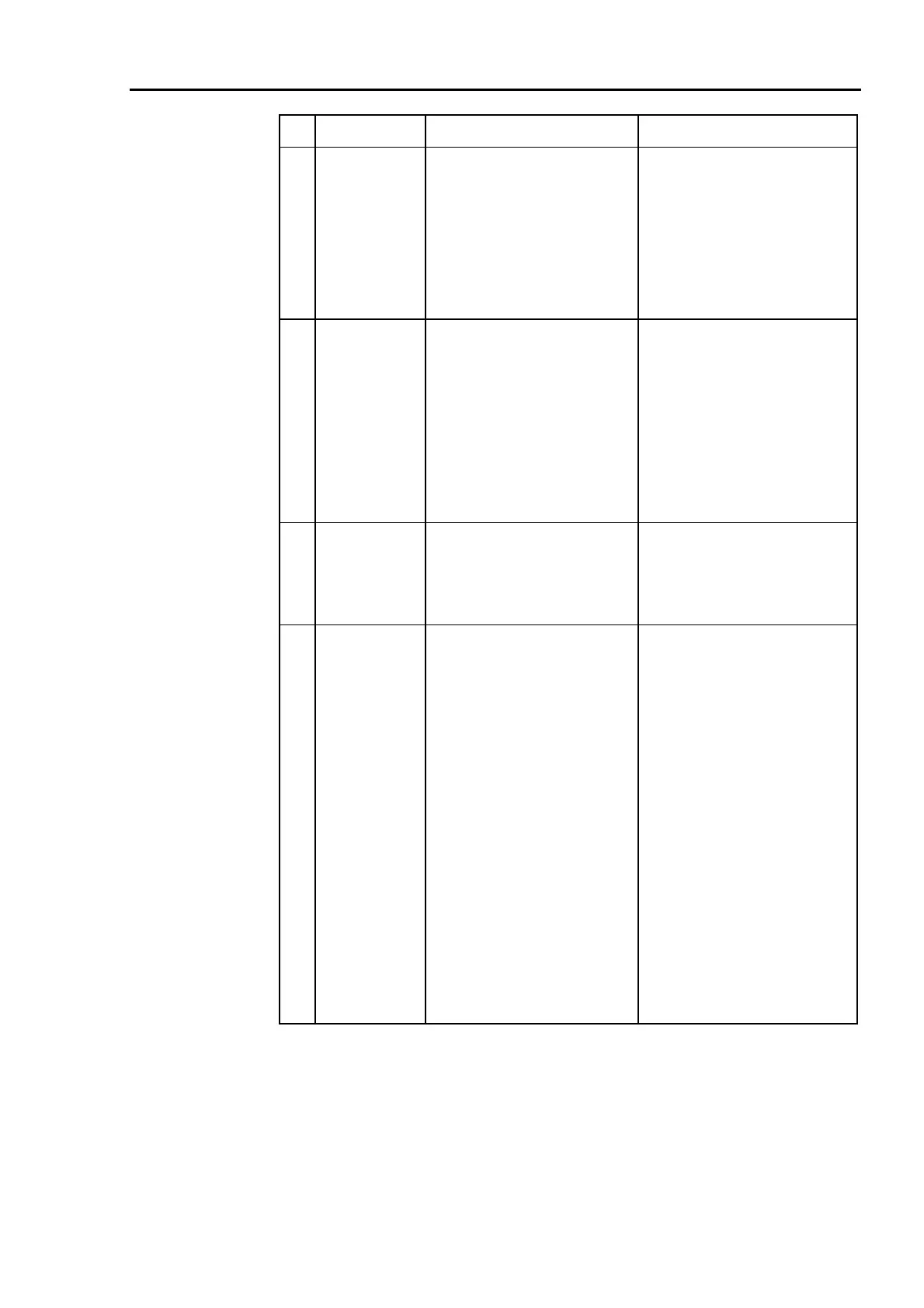

Name Specification NOTE

A

Silicon Rubber

Sheet

A sheet of 1 mm-thick silicon

rubber to be used for sealing

covers with liquid gasket

Make sure the rubber sheet has

been sealed up with the cover all

around by tightening the bolts

on the cover. Do not fasten the

bolts too tight. Fastening too

tight may cause the rubber to be

bulged out or torn.

B

Rubber

Packing

A ring-shaped rubber packing

to be applied on the duct joint

with liquid gasket

This packing does not need to

be detached when you follow

the maintenance operation

method described in this

manual.

Make sure that the rubber

packing has been sealed up.

Do not screw the duct joint too

tight. Screwing the joint too

tight may cause the rubber to be

bulged out or torn.

C

O-ring packing A rubber packing to be applied

on bellows, flange of reduction

gear, encoder reset cover and

main cable elbow fitting.

Make sure that the rings are not

squeezed nor deformed.

D

*Liquid gasket The liquid gasket supplied with

the manipulator to be applied

on the cover, plate, duct joint,

cable bracket, bolts, cable seal

box, and receptacle.

When using for covers, plates

and duct joint, apply the gasket

on its joint after installing the

cover, plate or duct joint.

When using for cable bracket,

bolts, cable seal box and

receptacle, apply the gasket on

one of the surfaces to be put

together before assembling.

Wipe the surplus.

The gasket dries in about 30

minutes and becomes rubbery in

15 to 16 hours in normal

temperature. For more details,

refer to the instructions printed

on the liquid gasket box.

*The liquid gasket for protected model is different from the gasket for standard and

clean model. Use the liquid gasket (1212).

Loading...

Loading...