Part 2: Maintenance 13. Protected Model Maintenance

213

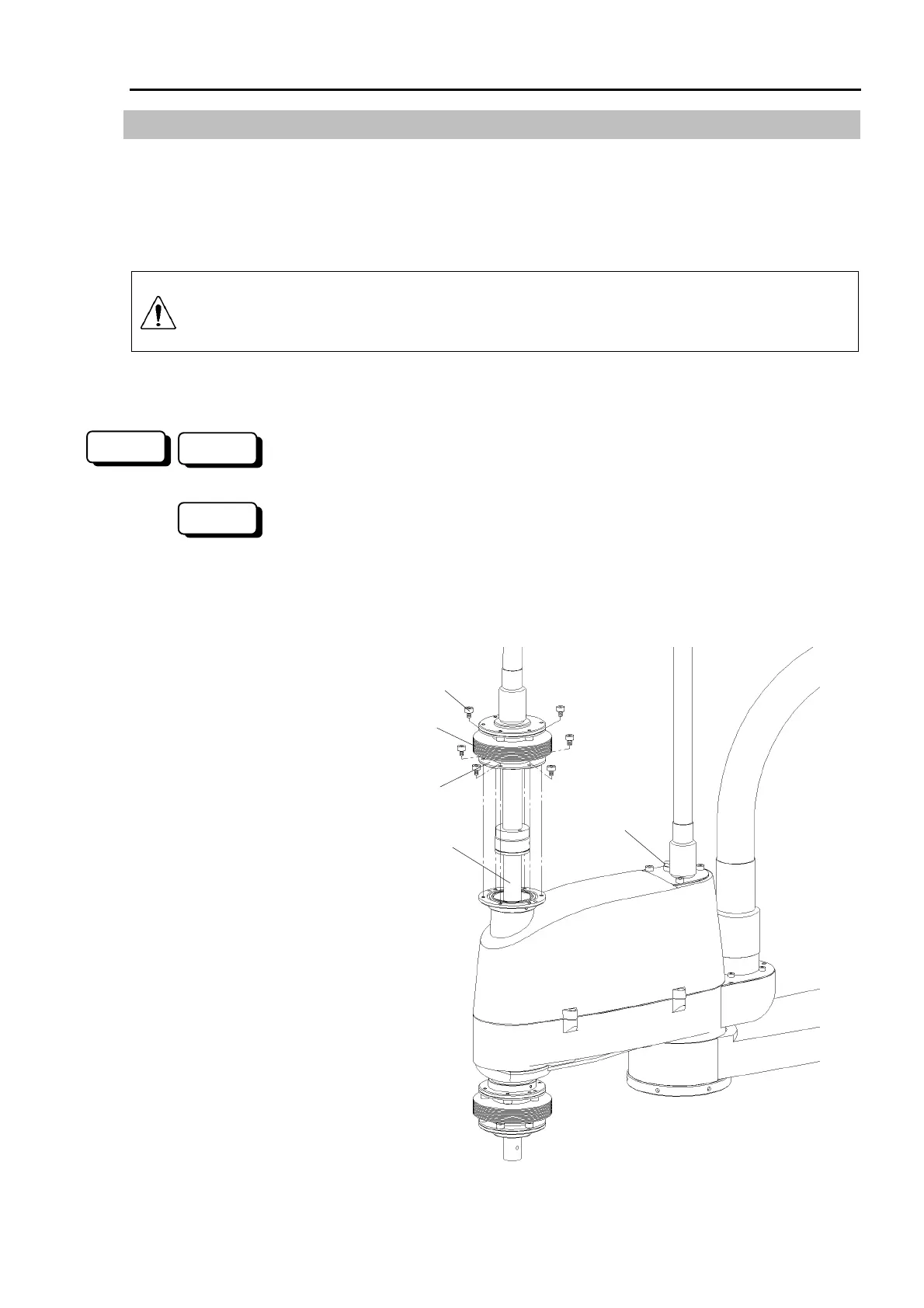

13.7 Greasing the Ball Screw Spline Unit

For basic information about the ball screw spline unit, refer to chapter 9. Replacing the Ball

Screw Spline Unit.

Follow the standards specifications concerning the type of grease to use and the areas to be

greased. Note that the bellows must be removed before greasing the shaft.

WARNING

When you open the bellows, do not allow water or any foreign substance to get

inside. Otherwise, electric shock or malfunction can occur when power is

connected.

When greasing, do not allow any grease to get on the outside of the bellows. Grease may

drip. Cover peripheral units with a sheet if necessary.

(1) Disengage the motors using the motor <OFF> button or command while keeping the

Drive Unit power ON.

(1) Disengage the motors using the MOTOR OFF command while keeping the Controller

power ON.

(2) Raise the shaft manually to its upper limit while pushing the brake release button.

(3) Remove the six bolts (M4×6) from the lower mounting ring of the upper bellows, then

slide the upper bellows upward.

Brake release

button

Upper bellows

Shaft

6-M4×6

Mounting ring

300

RC+

SPEL 95

Loading...

Loading...