Part 2: Maintenance 9. Replacing the Ball Screw Spline Unit

173

9.2 Greasing the Ball Screw Spline Unit

When greasing the ball screw spline unit, follow the procedure on this page.

∗ If the manipulator is a Clean model, refer to the section Greasing the Ball Screw

Spline Unit in chapter 12. Clean Model Maintenance.

∗ If the manipulator is a Protected model, refer to the section Greasing the Ball Screw

Spline Unit in chapter 13. Protected Model Maintenance.

(1) Disengage the motors from servo control using the motor <OFF> button on the Robot

Control Panel and keep the Drive Unit power ON.

(1) Disengage the motors by the MOTOR OFF command while keeping the Controller

power ON.

(2) Move the arm to a position where Joint #3 can be moved in full stroke. If necessary,

cover the surrounding area so that grease will not damage the end effector and

peripheral equipment, etc.

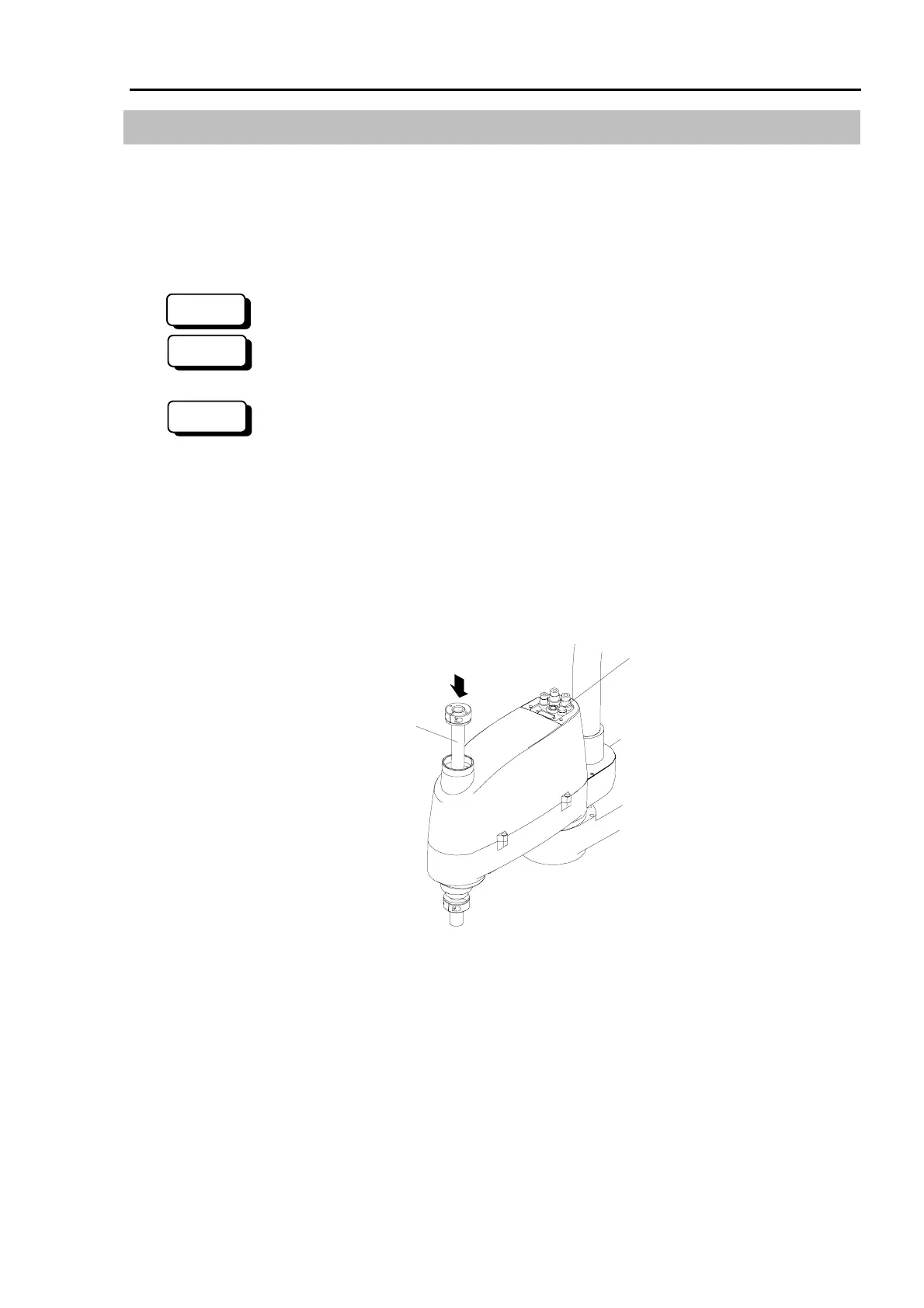

(3) Lower the shaft manually to its lower limit while pushing the Joint #3 brake release

button.

Push

Joint #3 brake release button

Shaft

(4) Fill the grooves on the lower end of the shaft with grease.

(5) Raise the shaft manually to its upper limit while pushing the brake release button.

(6) Fill the grooves on the upper end of the shaft with grease.

(7) Move the shaft up and down several times to smooth out the grease on the shaft.

Wipe off excess grease.

300

RC+

SPEL 95

Loading...

Loading...