13. Protected Model Maintenance Part 2: Maintenance

204

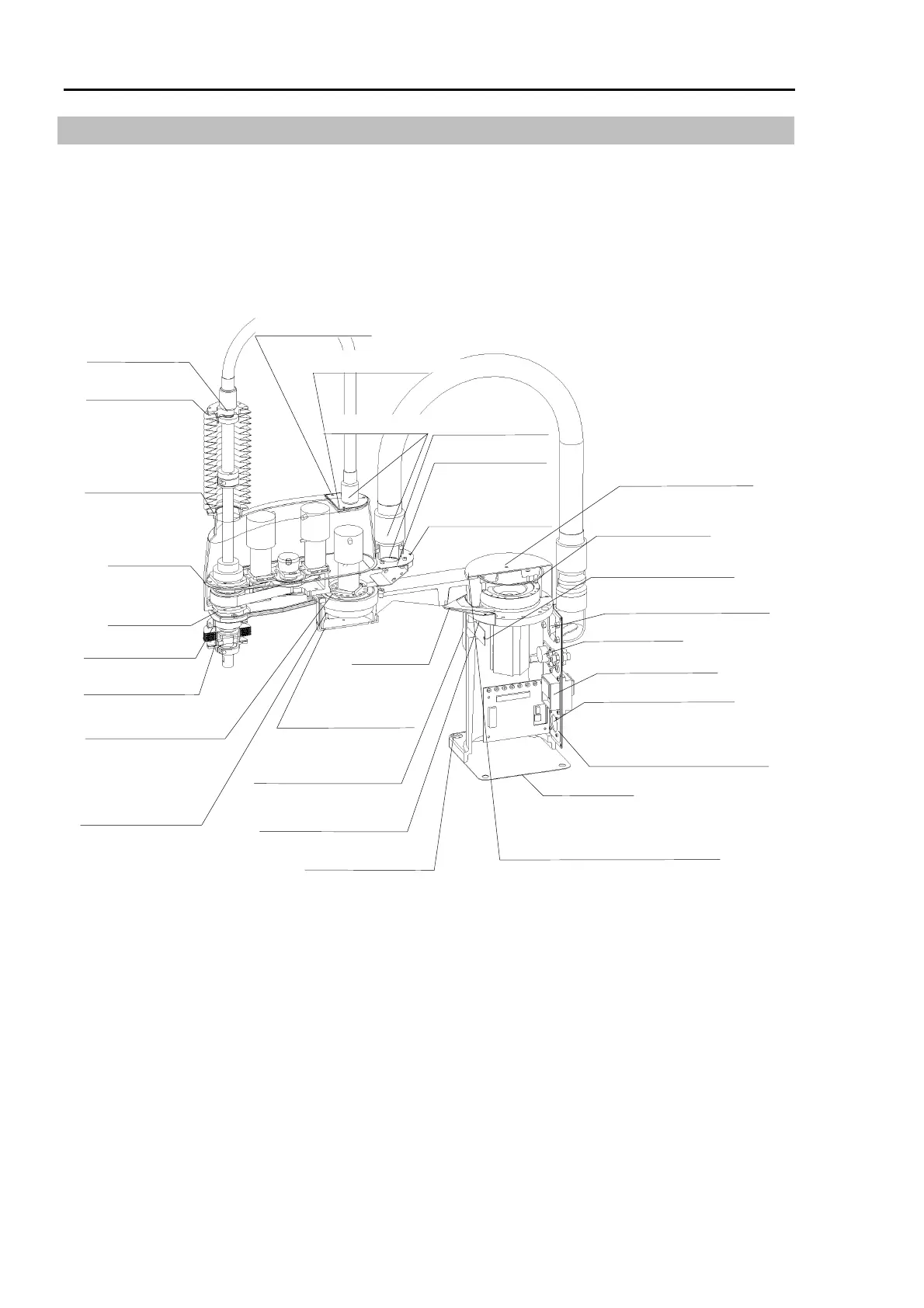

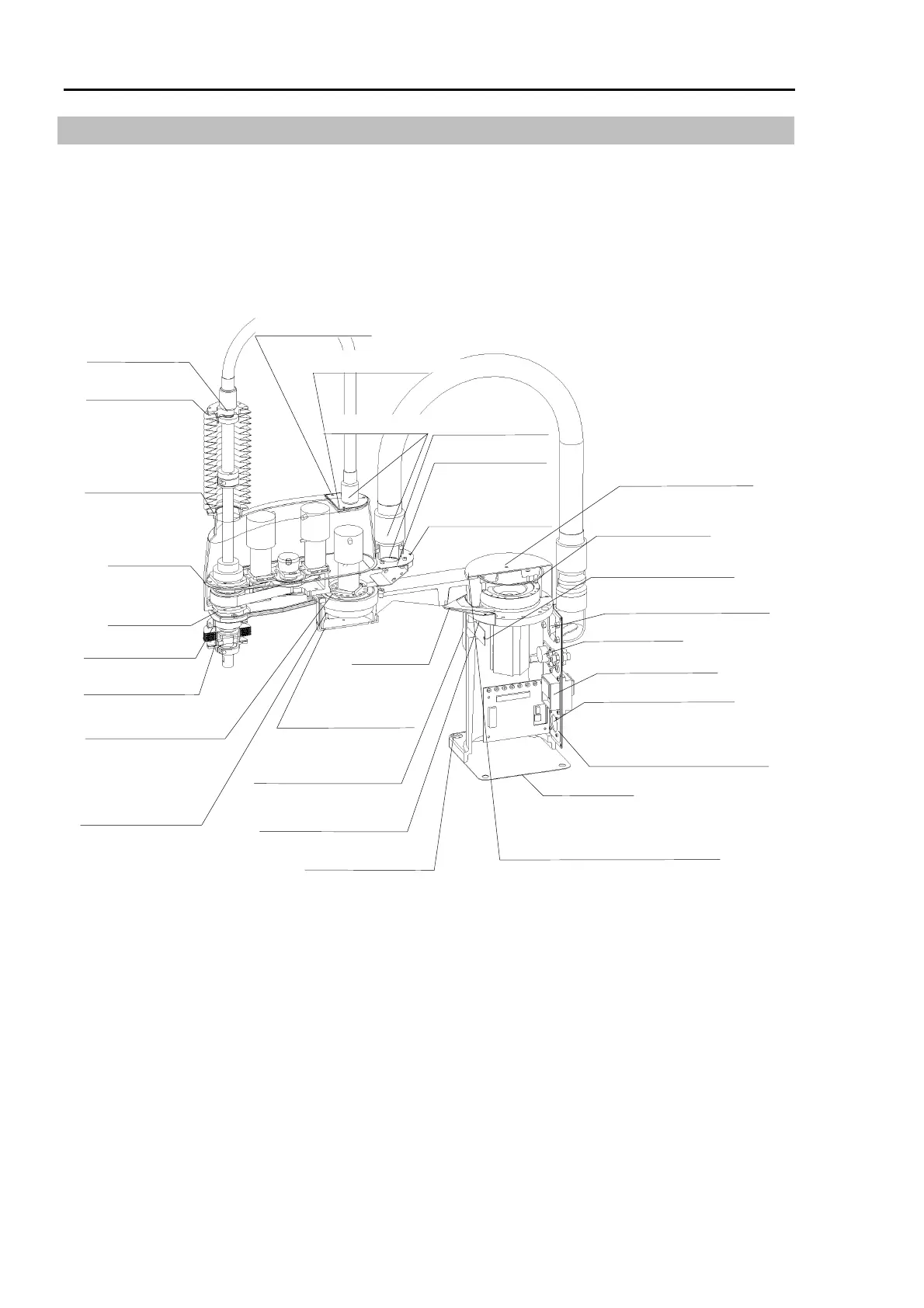

13.2 Sealing the Manipulator

The following figure shows all parts of the manipulator that must be sealed to prevent

moisture and dust. The figure also specifies the type of sealing for each part as types A, B,

C, and D.

If you break any of the seals, be sure to restore all sealing and air tightness after you finish

the maintenance operation.

Duct plate : D

Base plate : D

Maintenance plate : D

User plate

:

A+D

Receptacle : D

Cable seal box : D

Cable elbow fitting

:

C+D

Upper bellows : C

Upper bellows : C

Duct joint

:

B+D

Arm top

cover

:

A+D

Base connector plate

:

A+D

Joint #1 cover : A

Waterproof cover 2

:

watertight washers

Duct joint

:

B+D

Arm bottom

cover

:

A+D

Flange of Joint #1

reduction gear unit : C

Lower bellows : C

Lower bellows : C

Duct rotation : C

Flange of Joint #2

reduction gear unit: C

Bearing surface of

bolts for duct

plate : D

Bearing surface of

bolts for user plate

:

D

Bearing surface of

bolts for waterproof

cover3 : D

Watertight washers

Between waterproof cover 2 and

upper surface of Arm #1 : D

Arm 1# bottom

cover : D

Bearing surface of bolts

for waterproof cover 1:

D+ watertight washers

Encoder reset cover : C

Between Joint #2

reduction gear and

the arm #2 : C(ES)

D(EL)

Loading...

Loading...