Part 2: Maintenance 9. Replacing the Ball Screw Spline Unit

167

9. Replacing the Ball Screw Spline Unit

WARNING

Only trained personnel should be allowed to maintain this unit.

When replacing this unit, make sure the power is turned OFF and pull out the

power plug from the power source. Failure to turn OFF the power can result

in electric shock and malfunction.

When the motor and timing belts are removed while replacing the ball screw spline unit, the

mechanical origin position and therefore teach points change. (The mechanical origin

position is offset from the position saved in the Control Unit’s/Controller’s memory.) The

operation to offset the mechanical origin position is called “calibration.”

For calibration, the most suitable point to check the calibration accuracy must be selected

from the teach points. (Refer to chapter 11. Calibration.)

Types of ball screw spline units

There are six types of the ball screw spline unit. Specify the Z code when ordering a ball

screw spline unit for replacement.

Name

Stroke of Joint #3

Specification Old code New code

Ball screw spline unit for Z170

170 mm BNS2020A-385B

ZA001208 R13ZA00120800

Ball screw spline unit for Z320

320 mm BNS2020A-535B

ZA001209 R13ZA00120900

Clean model

Ball screw spline unit for Z150

150 mm BNS2020A-385B+CL

ZA001216

R13ZA00121600

Clean model

Ball screw spline unit for Z300

300 mm BNS2020A-535B+CL

ZA001217

R13ZA00121700

Protected model

Ball screw spline unit for Z150

150 mm BNS2020A-385B+P

ZA001218

R13ZA00121800

Protected model

Ball screw spline unit for Z300

300 mm BNS2020A-535B+P

ZA001219

R13ZA00121900

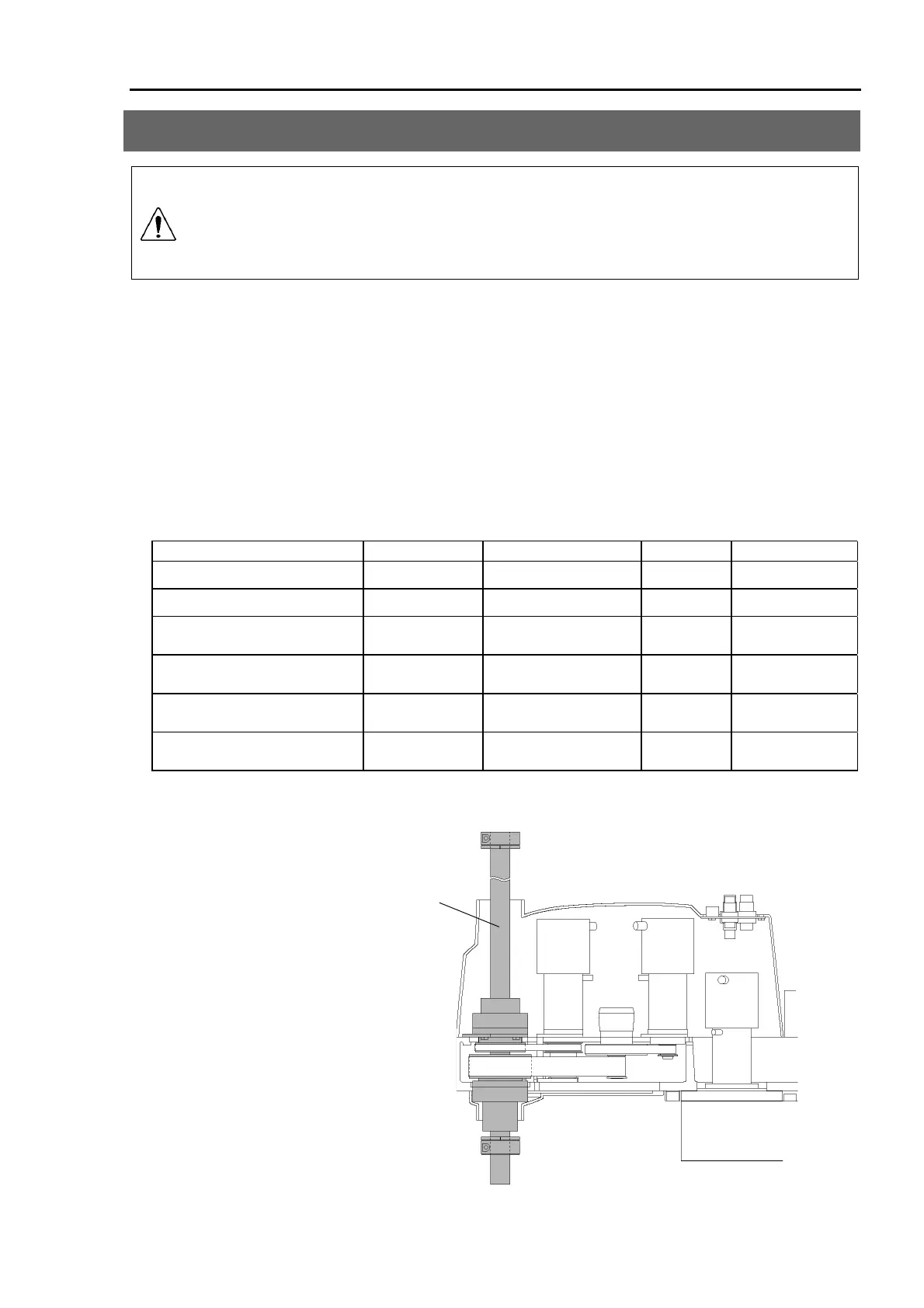

Location of the ball screw spline unit

Ball screw spline unit

NOTE

Loading...

Loading...