Part 2: Maintenance 8. Replacing the Timing Belts

155

8. Replacing the Timing Belts

WARNING

Only trained personnel should be allowed to maintain this part.

When replacing the timing belts, make sure the power is turned OFF and pull

out the power plug from the power source. Failure to turn OFF the power can

result in electric shock and malfunction.

Lower Joint #3 carefully to prevent it from colliding with nearby equipment. Joint #3 can

be moved while the brake release button (See Figure 11 in the chapter End Effectors in Part

1) is being pushed when the power is turned ON. The brake on the joint #3 motor, which

normally prevents the end effector lowering under its own weight when either the power or

the motor itself is turned OFF, does not work while the timing belt is being replaced.

The power should be OFF while replacing the timing belt.

Once the timing belt is removed or replaced, the origin position changes. As a result, the

teach points you have been using also deviate from position. In order to use the original

teach points, you need to adjust the origin position.

You need to choose one point from among the currently held teach points. The accuracy of

the selected point should be easy to check. Adjust the origin point as described in chapter

11. Calibration.

Types of timing belts

The timing belt is used one on Joint #3 and two on Joint #4. Specify the manipulator type

name and corresponding joint name when ordering a replacement timing belt.

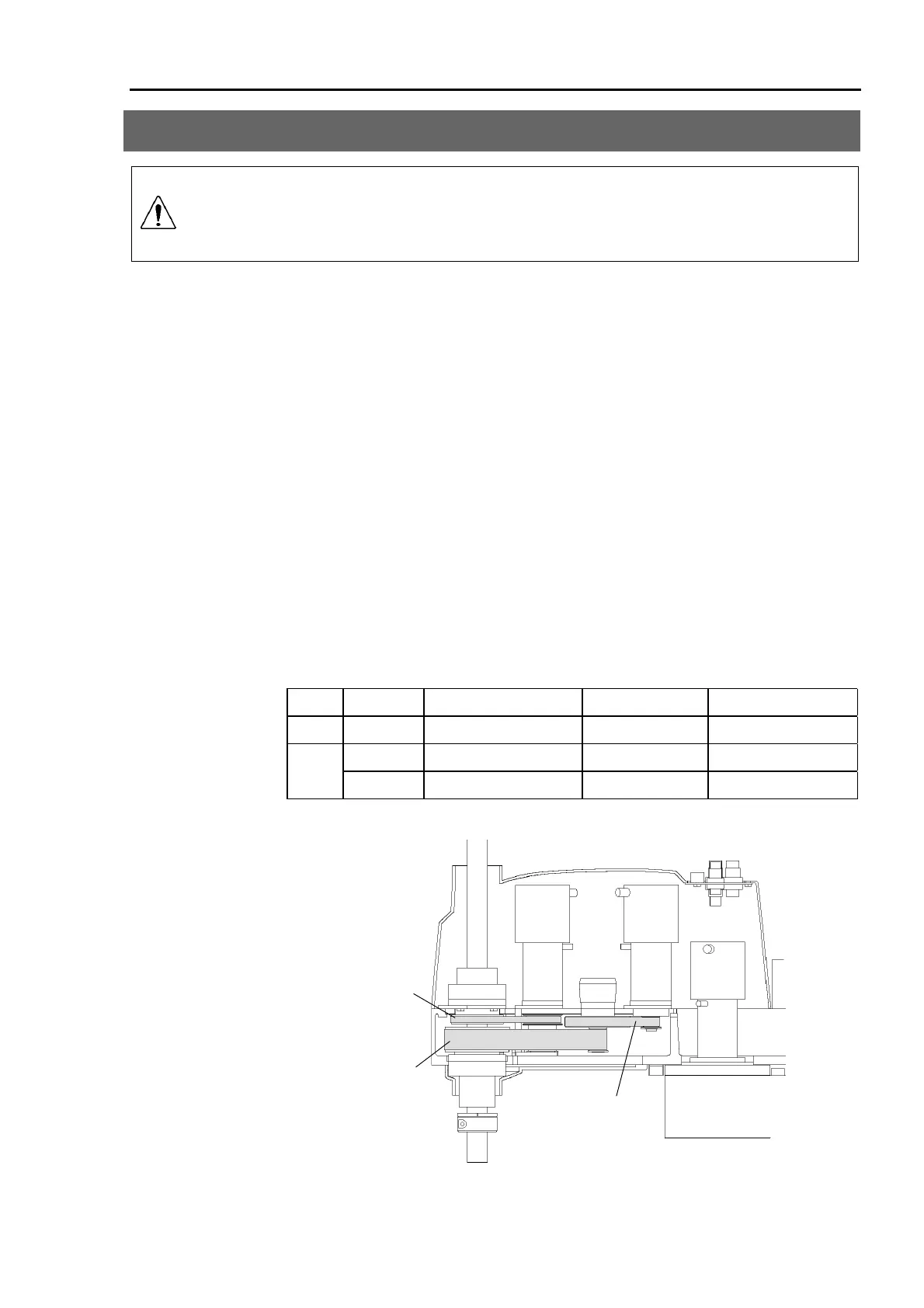

Joint Name Specification Old code New code

#3 Z belt 264-2GT-6 ZA003214 R13ZA00321400

U1 belt 264-2GT-9-T434N1 ZA003213 R13ZA00321300

#4

U2 belt 264-2GT-20-T434N1 ZA003212 R13ZA00321200

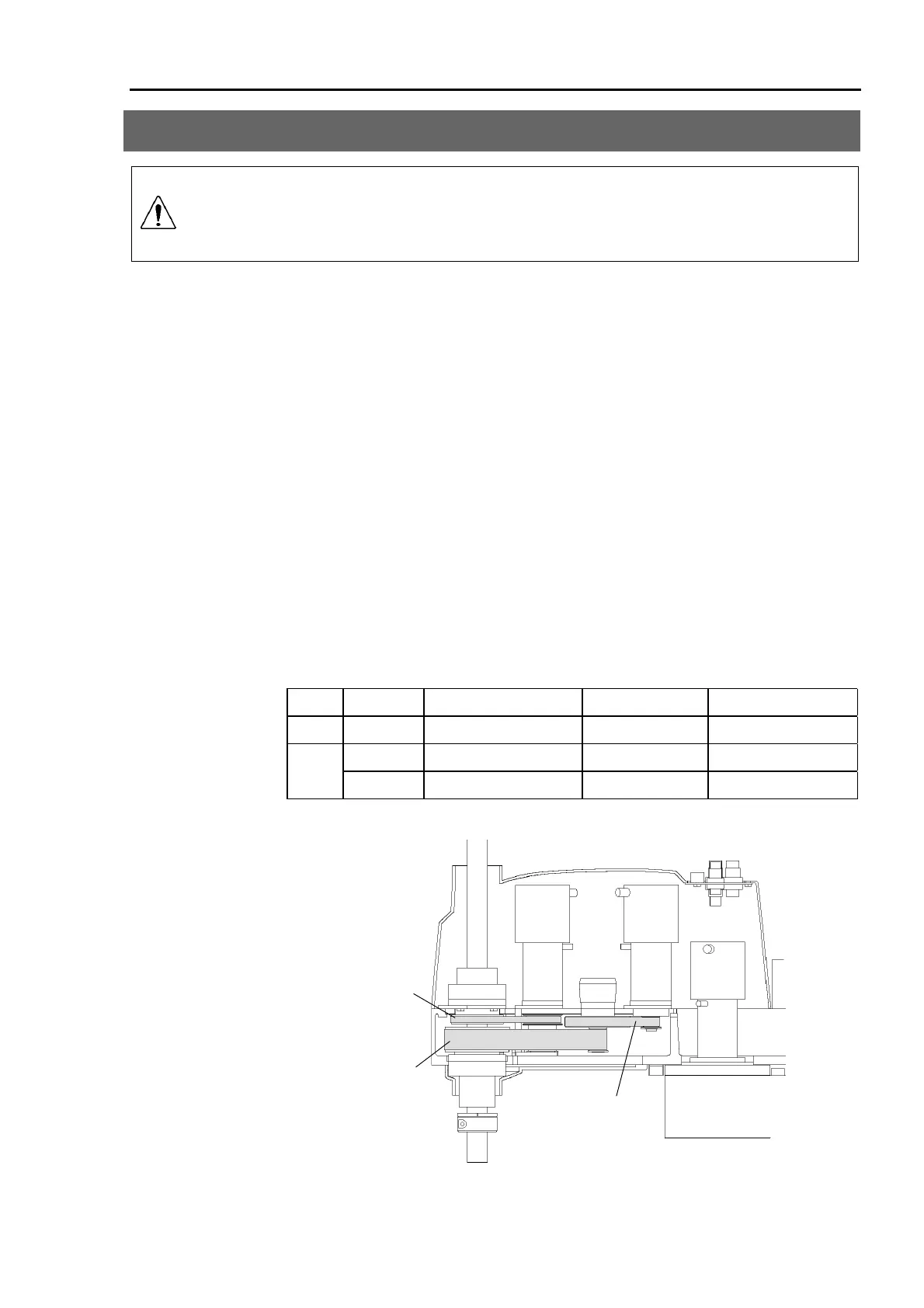

Locations of timing belts

Z belt (6 mm)

U2 belt (20 mm)

U1 belt (9 mm)

NOTE

NOTE

Loading...

Loading...