1. General Maintenance Part 2: Maintenance

86

1.3 Lubrication

For this manipulator, reduction gears and ball screw spline shaft are used.

These parts require lubrication or replacing grease periodically. If lubrication is not done

properly, and the manipulator is operated with insufficient grease, sliding parts will be

damaged and the efficiency of the manipulator will be reduced. Once these parts are

damaged, a lot of time and money will be required for repairs.

Only use the grease types specified in the following table.

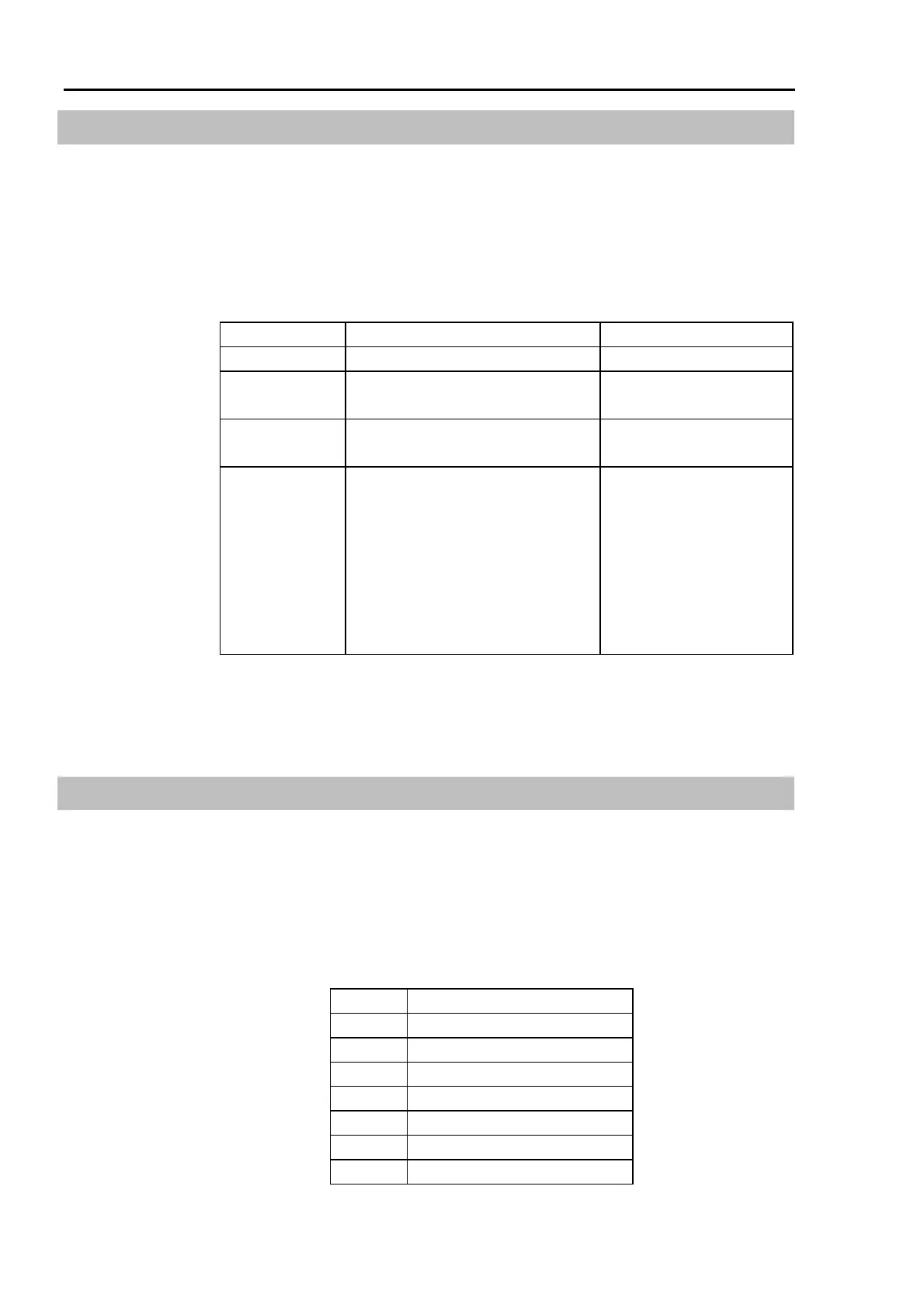

Position Joint #3 Joint #1 and #2

Greasing part Ball screw spline shaft Reduction gear unit

Greasing interval

First time: after 50 km operation

2nd or more: after 100 km operation

When replacing the motor

*

Grease type AFB grease (THK)

SK-1A

(Harmonic Drive Systems)

Refer to:

The section Greasing the Ball Screw

Spline Unit in 9. Replacing the Ball

Screw Spline Unit.

If the manipulator is a Clean model,

refer to chapter 11. Clean Model.

If the manipulator is a Protected

model, refer to chapter 13. Protected

Model.

6. Replacing the Reduction

Gear Unit.

*

It is not necessary to change grease of the reduction gear periodically under normal

condition, if the grease has been changed when replacing motor. However, in a case of

severe working condition (such as high duty, high speed, large loading, etc.), change

grease every 10,000 hours.

1.4 Tightening Torque of Bolts

Hexagon socket head cap bolts are used where mechanical strength is required in the

manipulator. At the time of construction, these bolts are fastened at the tightening torques

shown in the following table.

When additional tightening is necessary after inspection and when parts replacement is

necessary, tighten the bolts with a torque wrench.

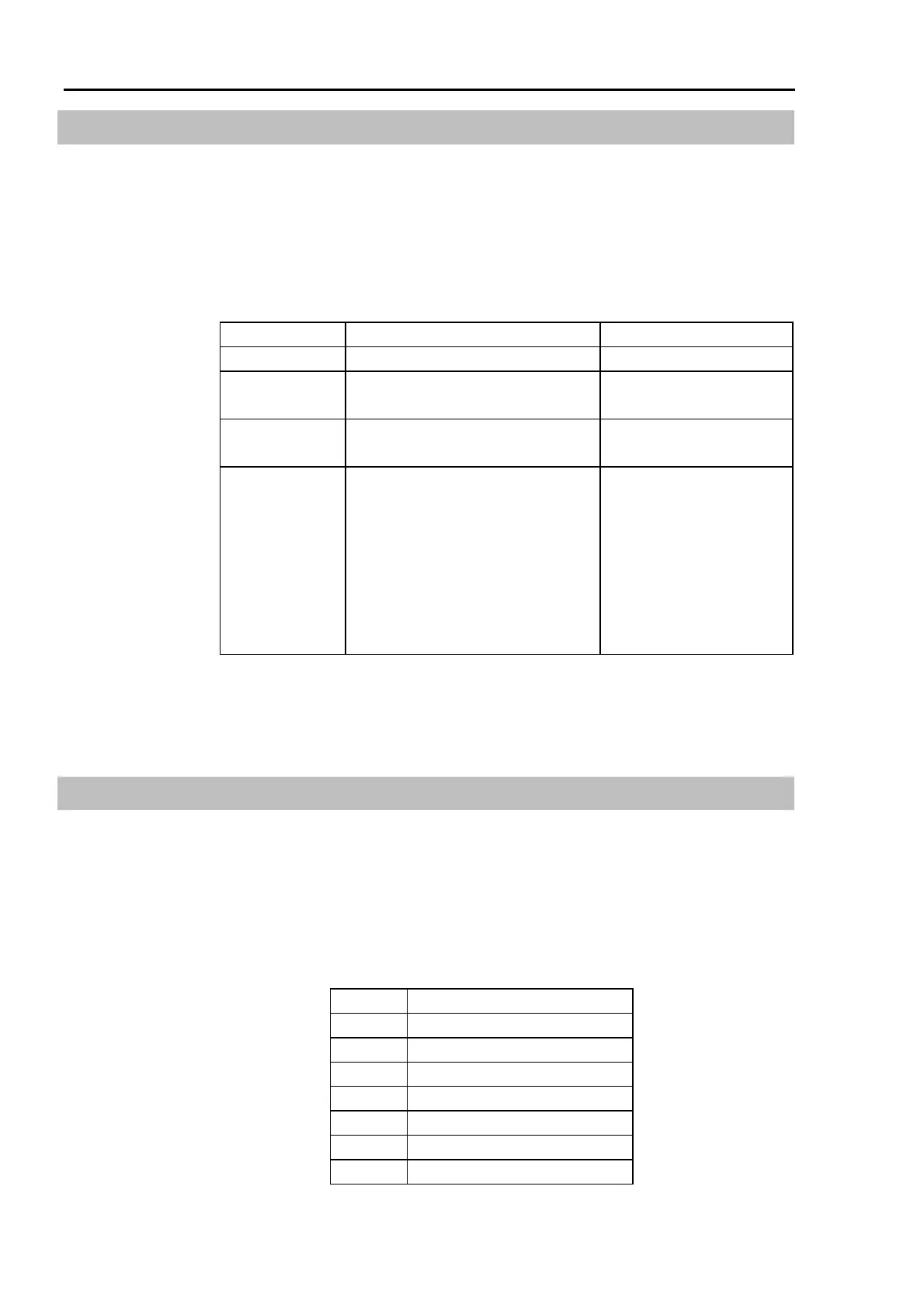

Bolts Tightening torque

M3

245 N⋅cm (25 kgf⋅cm)

M4

490 N⋅cm (50 kgf⋅cm)

M5

980 N⋅cm (100 kgf⋅cm)

M6

1760 N⋅cm (180 kgf⋅cm)

M8

3720 N⋅cm (380 kgf⋅cm)

M10

7350 N⋅cm (750 kgf⋅cm)

M12

12740 N⋅cm (1300 kgf⋅m)

Loading...

Loading...